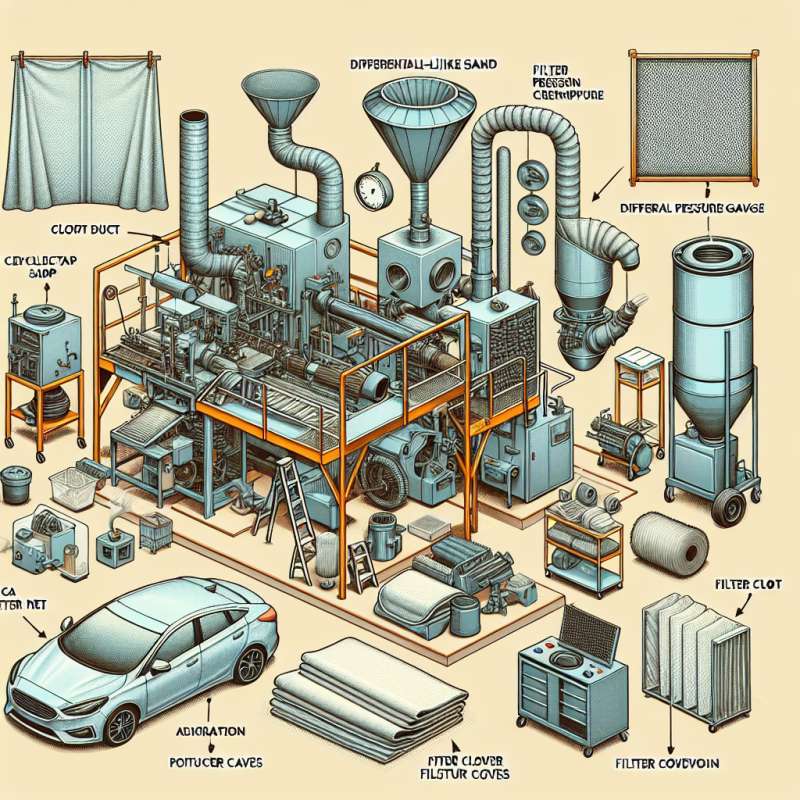

隨著全球環境問題日益嚴重,污染防治設備製造業正逐漸備受重視。在這個領域中,接板機、裁版機和配管等設備扮演著重要的角色,它們不僅可以提高生產效率,還能確保產品質量和符合環保標準。

未來發展趨勢顯示,智慧製造將成為污染防治設備製造業的主要方向。通過引入人工智慧、大數據和物聯網技術,製造商可以實現設備的自動化控制和監控,提高生產效率和產品質量。例如,配管設備可以通過智能感應器自動調節流量,從而節省能源和減少排放。

此外,污染防治設備製造業也將注重環保和可持續發展。製造商將致力於開發更環保的材料和技術,並加強污染防治設備的效能和耐用性。透過不斷創新和改進,這些設備將更好地滿足市場需求,同時保護環境和人類健康。

總的來說,未來污染防治設備製造業將朝著智慧製造和環保可持續發展的方向發展,接板機、裁版機和配管等設備將在這個過程中扮演著重要的角色。

Keywords: Board feeder, Cutting machine, Piping, Pollution control equipment manufacturing

Title: Future Trends: The Application of Smart Manufacturing in Pollution Control Equipment Manufacturing

Article: With the increasing severity of global environmental issues, the pollution control equipment manufacturing industry is gradually gaining more attention. In this field, equipment such as board feeders, cutting machines, and piping play important roles, not only improving production efficiency but also ensuring product quality and compliance with environmental standards.

Future trends indicate that smart manufacturing will become the main direction of the pollution control equipment manufacturing industry. By introducing artificial intelligence, big data, and Internet of Things technology, manufacturers can achieve automation control and monitoring of equipment, enhancing production efficiency and product quality. For example, piping equipment can automatically adjust flow rates through smart sensors, saving energy and reducing emissions.

Furthermore, the pollution control equipment manufacturing industry will also focus on environmental protection and sustainable development. Manufacturers will strive to develop more environmentally friendly materials and technologies, and enhance the efficiency and durability of pollution control equipment. Through continuous innovation and improvement, these equipment will better meet market demands while protecting the environment and human health.

In conclusion, the future of the pollution control equipment manufacturing industry will move towards smart manufacturing and environmentally sustainable development, with board feeders, cutting machines, and piping playing important roles in this process.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)