工業自動化吸盤和機械手臂吸嘴是現代製造業中不可或缺的橡膠製品。它們廣泛應用於機器人、自動組裝線、物料處理、包裝等工業領域。這些吸盤和吸嘴關乎製造業的效率和品質,所以選擇適合的橡膠材料至關重要。

矽橡膠是一種常用的橡膠材料,具有耐高溫、抗腐蝕和耐化學物質侵蝕的特性。矽橡膠可承受極低和極高溫度,使得工業自動化吸盤和機械手臂吸嘴能在各種環境中使用。矽橡膠还具有抗靜電特性,避免靜電對製造過程帶來的干擾和危害。

彈簧橡膠防塵套是另一個重要的橡膠製品。它們通常用於保護機械零件免受灰塵、水分和其他污染物的影響。彈簧橡膠防塵套具有彈性,可根據機械零件的運動進行伸縮。這些防塵套通常是使用耐高溫的矽橡膠製成,以便在高溫環境中使用。

在工業製造中,關乎生產效率的一個關鍵因素是能夠快速更換和維修機械部件。這時,矽橡膠的優點再次體現。矽橡膠可以進行客製化設計,根據不同的機器和部件的要求進行製造,例如定製O-Ring或其他橡膠零件。此外,矽橡膠還具有高透光性,可以用於光學儀器和面板的製造。

結論上,工業自動化吸盤和機械手臂吸嘴以及其他橡膠製品在現代製造業中起著至關重要的作用。合適的橡膠材料如矽橡膠能夠提供兼具高溫耐性、抗靜電、彈性和防塵等特性,以確保生產線的順利運作和產品的品質符合要求。

關鍵字: Industrial Automation Suction Cup, Robotic Arm Nozzle, Silicone Rubber, Silicone Chemical, Spring Rubber Dust Cover

標題: The Importance of Industrial Automation Suction Cups and Robotic Arm Nozzles

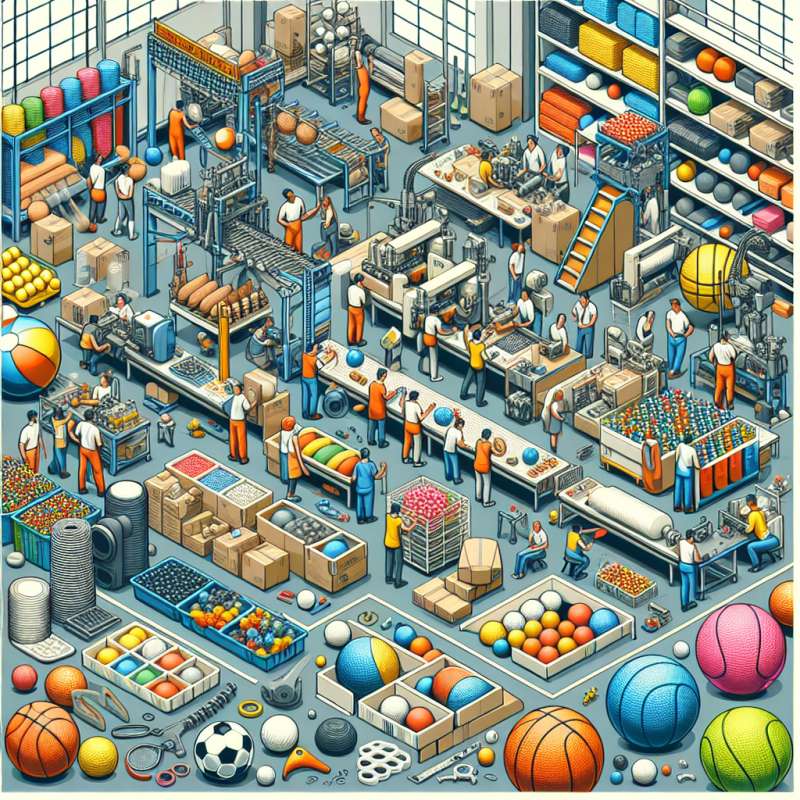

Industrial automation suction cups and robotic arm nozzles are indispensable rubber products in modern manufacturing industries. They are widely used in robotics, automated assembly lines, material handling, packaging, and other industrial applications. The efficiency and quality of these suction cups and nozzles are crucial, making it essential to select the appropriate rubber materials.

Silicone rubber is a commonly used rubber material known for its high temperature resistance, corrosion resistance, and resistance to chemical substances. Silicone rubber can withstand extremely low and high temperatures, allowing industrial automation suction cups and robotic arm nozzles to be used in various environments. Silicone rubber also possesses anti-static properties, preventing the interference and potential hazards caused by static electricity during the manufacturing process.

Another important rubber product is the spring rubber dust cover. They are typically used to protect mechanical components from dust, moisture, and other contaminants. Spring rubber dust covers are elastic, allowing them to expand and contract according to the movement of mechanical parts. These dust covers are often made from high-temperature resistant silicone rubber for use in hot environments.

In industrial manufacturing, the ability to quickly change and maintain machine parts is a key factor in production efficiency. This is where the advantages of silicone rubber come into play. Silicone rubber can be customized to meet the specific requirements of different machines and components, such as custom-made O-rings or other rubber parts. Additionally, silicone rubber has excellent transparency, making it suitable for the manufacturing of optical instruments and panels.

In conclusion, industrial automation suction cups, robotic arm nozzles, and other rubber products play a crucial role in modern manufacturing. Suitable rubber materials such as silicone rubber can provide high temperature resistance, anti-static properties, elasticity, and dust protection to ensure smooth operation of production lines and meet product quality requirements.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)