隨著科技的進步,製造業在製程監控與品質管理方面也有了新的發展趨勢。製程監控是指在生產過程中對各個環節進行監控,以確保產品符合標準。而品質管理則是指通過各種手段來確保產品的良品率,減少不良品的產生。

未來製造業將更加重視製程監控和品質管理,以提高產品的品質和競爭力。其中,監控系統將朝著自動化和智能化方向發展,可以實時監控製程中的各個參數,及時發現問題並進行調整。品管方面也將更加注重數據分析和預測,以提前發現潛在問題並加以解決。

在未來,製造業將更加注重良品率的提高,減少不良品的產生。透過製程監控和品質管理的手段,可以有效地提高產品的良品率,降低不良品率,提升企業的競爭力。

Keywords: monitoring, process, quality control, good product, defective

Title: Future Trends in Process Monitoring and Quality Management

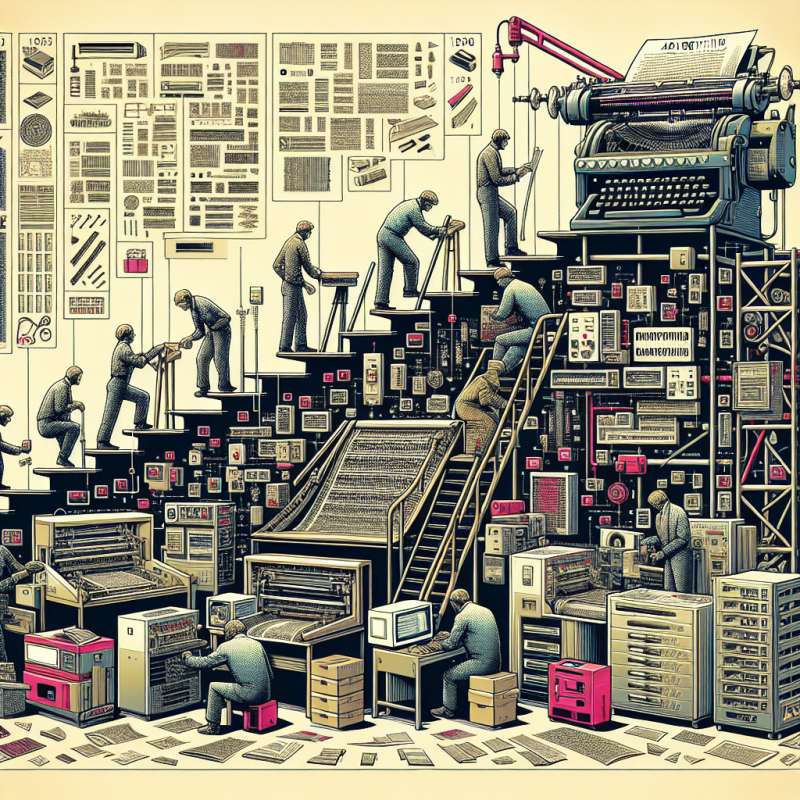

Article: With the advancement of technology, the manufacturing industry has seen new trends in process monitoring and quality management. Process monitoring involves monitoring various aspects of the production process to ensure that the products meet standards. Quality management, on the other hand, involves various methods to ensure the quality of products, reducing the occurrence of defects.

In the future, the manufacturing industry will pay more attention to process monitoring and quality management to improve product quality and competitiveness. Monitoring systems will evolve towards automation and intelligence, allowing real-time monitoring of various parameters in the process to detect and adjust issues promptly. Quality control will also focus more on data analysis and prediction to identify potential problems in advance.

In the future, the manufacturing industry will emphasize increasing the rate of good products and reducing the occurrence of defects. Through process monitoring and quality management, companies can effectively improve the rate of good products, reduce the rate of defects, and enhance their competitiveness.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)