隨著科技的進步和市場需求的不斷變化,瓦楞紙板(箱)製造業正逐漸走向自動化和多功能化的方向。許多工廠已經開始導入全自動化的生產線,以提高生產效率和品質。這種趨勢不僅可以降低人力成本,還可以減少生產過程中的錯誤和廢品率。

在日本,許多瓦楞紙板製造商已經承諾將更多的資源投入自動化技術的研發和應用。他們希望通過提高生產效率和產品質量,來滿足不斷增長的市場需求。同時,瓦楞紙板製造商也開始研發兩用式的紙袋,以滿足消費者對環保和多功能性的需求。

未來,瓦楞紙板製造業將會更加注重自動化和多功能化的發展。這不僅可以提高生產效率和品質,還可以滿足消費者對環保和便利性的需求。總的來說,瓦楞紙板製造業將會在不斷創新和改進的過程中,迎接更廣闊的市場前景。

Keywords: Automation, Multifunctional, Factory, Commitment, Paper bags

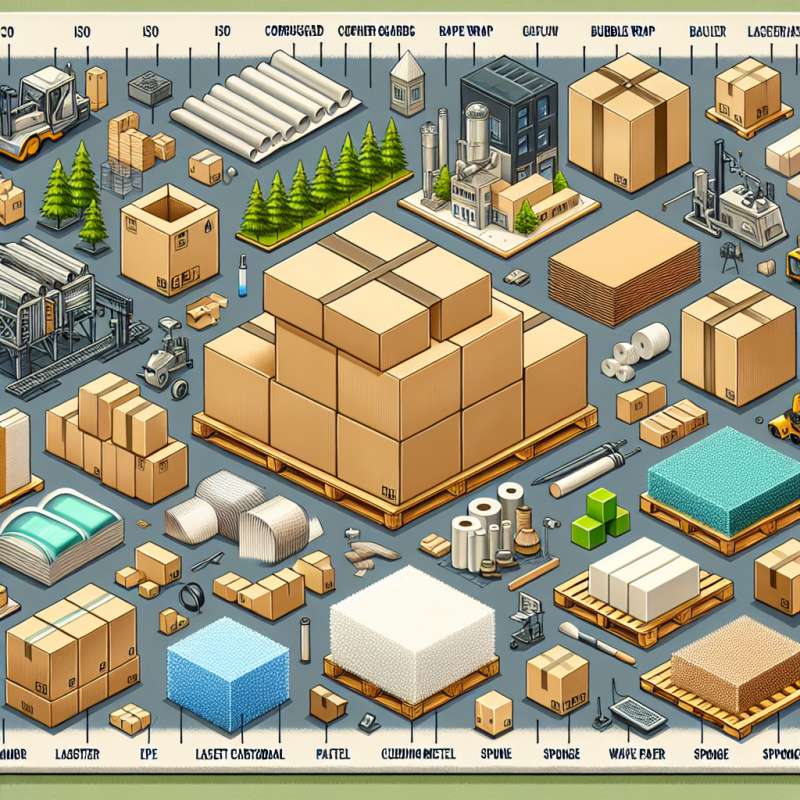

Title: Future Trends in Corrugated Cardboard Manufacturing Industry

Article: With the advancement of technology and the ever-changing market demands, the corrugated cardboard manufacturing industry is gradually moving towards automation and multifunctionality. Many factories have already started to implement fully automated production lines to improve production efficiency and quality. This trend not only reduces labor costs but also decreases errors and waste during the production process.

In Japan, many corrugated cardboard manufacturers have committed to investing more resources in the research and application of automation technology. They aim to meet the growing market demand by enhancing production efficiency and product quality. At the same time, corrugated cardboard manufacturers are also developing dual-use paper bags to meet consumers' needs for environmental protection and multifunctionality.

In the future, the corrugated cardboard manufacturing industry will focus more on the development of automation and multifunctionality. This will not only improve production efficiency and quality but also meet consumers' demands for environmental protection and convenience. Overall, the corrugated cardboard manufacturing industry will embrace broader market prospects through continuous innovation and improvement.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)