橡膠工業製品一直以來都在不斷地演進和創新。隨著施工、機械和工業領域的持續發展,橡膠襯套、工業橡膠製品和其他塑膠製品的需求也越來越大。本文將探討橡膠工業產品的未來發展趨勢以及相關的創新。

ISO(國際標準化組織)是一個全球性的標準制定機構,它能夠為橡膠製品制造商提供統一的品質和安全標準。遵循ISO標準將有助於促進國際貿易和提高產品競爭力。因此,橡膠製品制造商應該致力於獲得相關的ISO認證。

PVC(聚氯乙烯)是一種常用的塑料材料,廣泛應用於橡膠製品的生產。由於其良好的耐久性和可塑性,PVC製品在建築、家具和汽車等行業中非常受歡迎。

Rubberlining(橡膠襯套)是一種將橡膠層覆蓋在不同材質的表面上以提供保護的技術。橡膠襯套不僅可以提高材料的耐磨性和耐腐蝕性,還可以減緩振動和聲音。橡膠襯套被廣泛應用於各種工業領域,如化學工業、油氣行業和礦業等。

隨著中國大陸在資訊和通信技術領域的快速發展,橡膠製品製造商應該利用這些資訊技術來提高生產效率和品質控制。這將包括使用數據分析、自動化和物聯網技術來追蹤製造過程中的關鍵參數。這些資訊技術的應用將使橡膠製品製造商能夠更加靈活地應對市場需求並提供更高質量的產品。

未來,創新將是橡膠工業的重要驅動力。橡膠製品製造商應該不斷地尋求新的材料和製造技術,以提高產品的功能性和可持續性。例如,開發可回收和生物可降解的橡膠製品將有助於減少對環境的影響。

橡膠工業還應該關注污染防治設備的製造。隨著環境保護意識的提高,對於污染防治設備的需求也在增加。橡膠製品製造商可以通過開發高效、節能的污染防治設備來滿足市場需求。

最後,安全帽的製造將繼續成為橡膠工業的一個重要領域。隨著對工地安全的關注不斷增加,對高品質安全帽的需求也在增長。橡膠製品製造商可以通過利用新材料和技術,開發更輕量、舒適和保護性能更好的安全帽。

橡膠工業產品的未來發展趨勢將受到ISO標準、PVC材料、橡膠襯套、資訊技術和創新的影響。橡膠製品製造商應該密切關注這些趨勢,並采取相應的措施以提高產品的競爭力和市場地位。

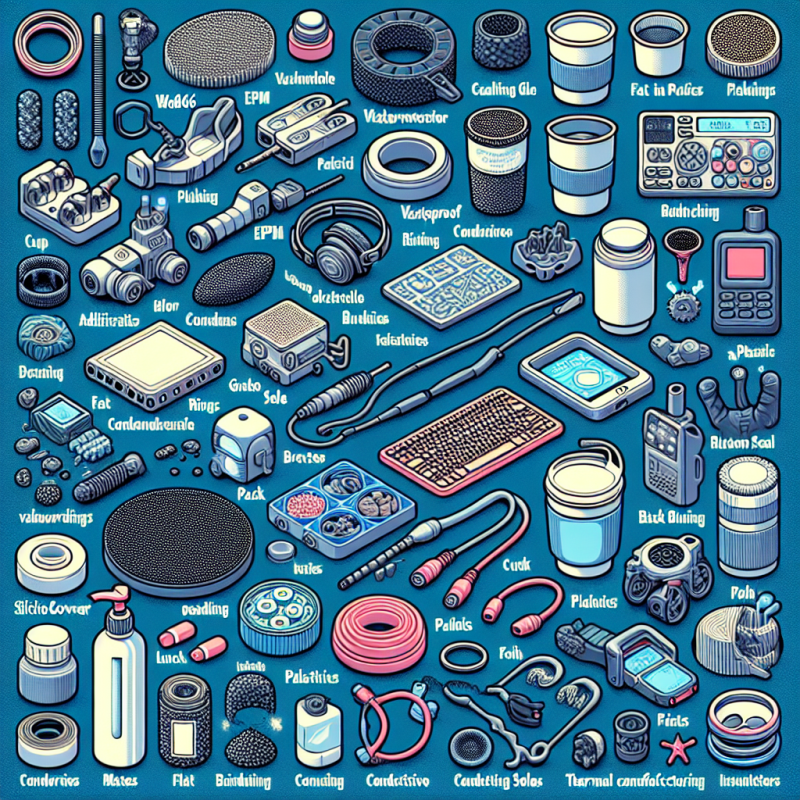

關鍵字: ISO, PVC, Rubberlining, 橡膠襯套, 資訊, 創新, 機械, 施工, 材料, 未分類其他塑膠製品製造, 安全帽製造, 污染防治設備製造, 工業用橡膠製品製造

標題: The Future Trends and Innovations in the Rubber Industry

The rubber industry has been continuously evolving and innovating. With the ongoing development in the construction, machinery, and industrial sectors, the demand for rubber linings, industrial rubber products, and other plastic products is increasing. This article explores the future trends and relevant innovations in the rubber industry.

ISO (International Organization for Standardization) is a global standard-setting body that provides unified quality and safety standards for rubber product manufacturers. Complying with ISO standards will facilitate international trade and enhance product competitiveness. Therefore, rubber product manufacturers should strive to obtain relevant ISO certifications.

PVC (Polyvinyl Chloride) is a commonly used plastic material that is widely used in the production of rubber products. Due to its excellent durability and versatility, PVC products are highly popular in industries such as construction, furniture, and automotive.

Rubber lining is a technique of applying a layer of rubber to the surface of materials to provide protection. Rubber linings not only improve the wear resistance and corrosion resistance of materials but also help reduce vibration and noise. Rubber linings are extensively used in various industrial sectors such as chemical, oil and gas, and mining.

With the rapid development of information and communication technology in Mainland China, rubber product manufacturers should utilize these information technologies to improve production efficiency and quality control. This will include the use of data analytics, automation, and Internet of Things (IoT) technologies to track key parameters during the manufacturing process. The application of these information technologies will enable rubber product manufacturers to respond more flexibly to market demands and provide higher-quality products.

Innovation will be a driving force in the future of the rubber industry. Rubber product manufacturers should continuously seek new materials and manufacturing technologies to enhance product functionality and sustainability. For example, the development of recyclable and biodegradable rubber products will help reduce the environmental impact.

The rubber industry should also focus on the manufacturing of pollution control equipment. With the increasing awareness of environmental protection, the demand for pollution control equipment is growing. Rubber product manufacturers can meet market demands by developing efficient and energy-saving pollution control equipment.

Lastly, the manufacturing of safety helmets will continue to be an important area in the rubber industry. With the increasing focus on workplace safety, the demand for high-quality safety helmets is also growing. Rubber product manufacturers can develop lighter, more comfortable, and better protective performance safety helmets by utilizing new materials and technologies.

The future trends in the rubber industry will be influenced by ISO standards, PVC materials, rubber linings, information technology, and innovation. Rubber product manufacturers should closely monitor these trends and take corresponding measures to enhance product competitiveness and market position.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)