近年來,隨著科技的進步和市場需求的不斷增加,塑膠包材產業也逐漸走向多元化和智能化的發展。其中,IML(In-Mold Labeling)技術作為一種新興的包裝方式,逐漸受到製造商的青睞。IML技術是將熱轉印膜與模內標籤結合,直接在模具使用過程中將標籤與塑膠包材融合在一起,使得包裝更加美觀和耐用。

熱轉印機作為IML技術的重要設備,也在不斷升級和改進,以滿足市場對高效率和高品質包裝的需求。未來,隨著消費者對個性化包裝的追求不斷增加,塑膠包材將更加注重印刷和設計的創新,以滿足不同客戶的需求。

除了IML技術,塑膠包材的未來發展趨勢還包括HTF(Heat Transfer Film)技術的應用。HTF技術是一種將薄膜通過熱轉印的方式,將圖案或文字轉移到塑膠包裝上的技術,可以實現更加豐富多彩的包裝效果。

總的來說,塑膠包材產業將朝著智能化、個性化和環保化的方向發展,不斷引入新技術和新材料,以滿足市場對包裝的不斷變化的需求。

Keywords: IML, Heat Transfer Machine, In-Mold Label, Plastic Packaging, Future Development Trends

Title: Future Development Trends of Plastic Packaging

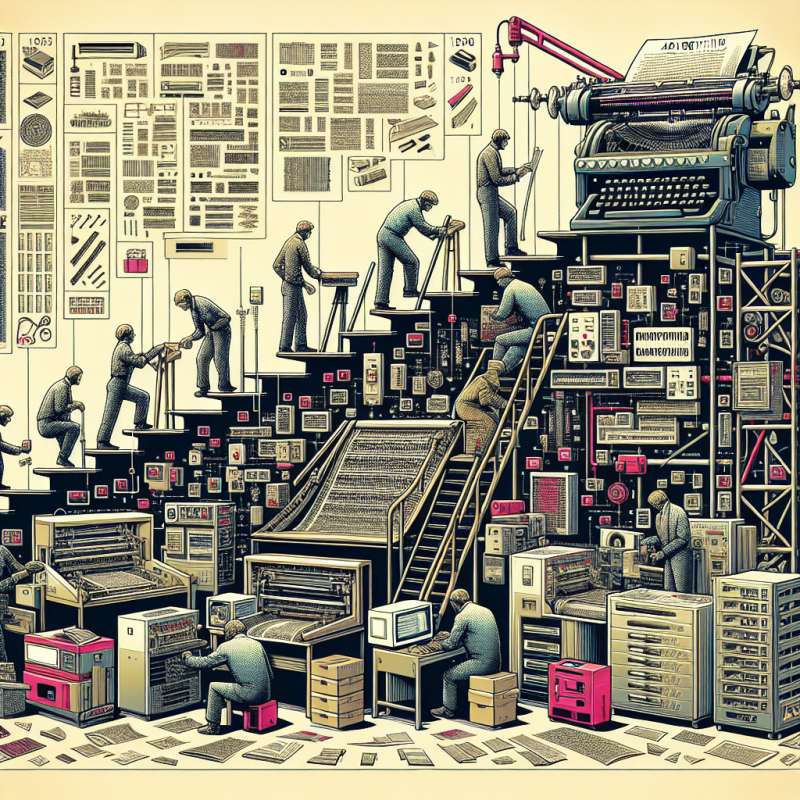

Article: In recent years, with the advancement of technology and the increasing market demand, the plastic packaging industry is gradually moving towards diversification and intelligent development. Among them, IML (In-Mold Labeling) technology, as an emerging packaging method, is gradually favored by manufacturers. IML technology combines heat transfer film with in-mold labels, directly integrating labels with plastic packaging in the mold during the molding process, making the packaging more attractive and durable.

As an important equipment for IML technology, heat transfer machines are also continuously upgraded and improved to meet the market's demand for efficient and high-quality packaging. In the future, as consumers' pursuit of personalized packaging continues to increase, plastic packaging will pay more attention to the innovation of printing and design to meet the needs of different customers.

In addition to IML technology, the future development trend of plastic packaging also includes the application of HTF (Heat Transfer Film) technology. HTF technology is a way to transfer patterns or text onto plastic packaging through heat transfer film, achieving more colorful packaging effects.

Overall, the plastic packaging industry will develop towards intelligence, personalization, and environmental protection, continuously introducing new technologies and materials to meet the ever-changing demands of the packaging market.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)