隨著科技的進步和全自動製造生產技術的應用,塑膠製造工廠正逐漸走向全自動化的生產模式。在過去,塑膠製造通常需要大量人力投入,但現在隨著全自動化設備的普及,製造過程更加高效和精確。

塑膠皮、塑膠布製造是塑膠製造工廠中的重要環節之一,全自動化生產線可以大大提高生產效率和產品質量。此外,塑膠板、管材等製造也可以透過全自動化設備來實現更高水準的生產。

未來,隨著全自動化技術的不斷發展和應用,塑膠製造工廠將更加智能化和高效化。透過自動化的生產線,工廠可以實現更快速的生產速度和更低的生產成本,同時提高產品的品質和一致性。

在這個全自動化的時代,塑膠製造工廠將朝著更智能、更環保的方向發展,為塑膠製品的生產帶來更多可能性和機遇。

Keywords: fully automated, manufacturing production, plastic film and fabric manufacturing, factory, future development trends

Title: Future Development Trends of Plastic Manufacturing Factories

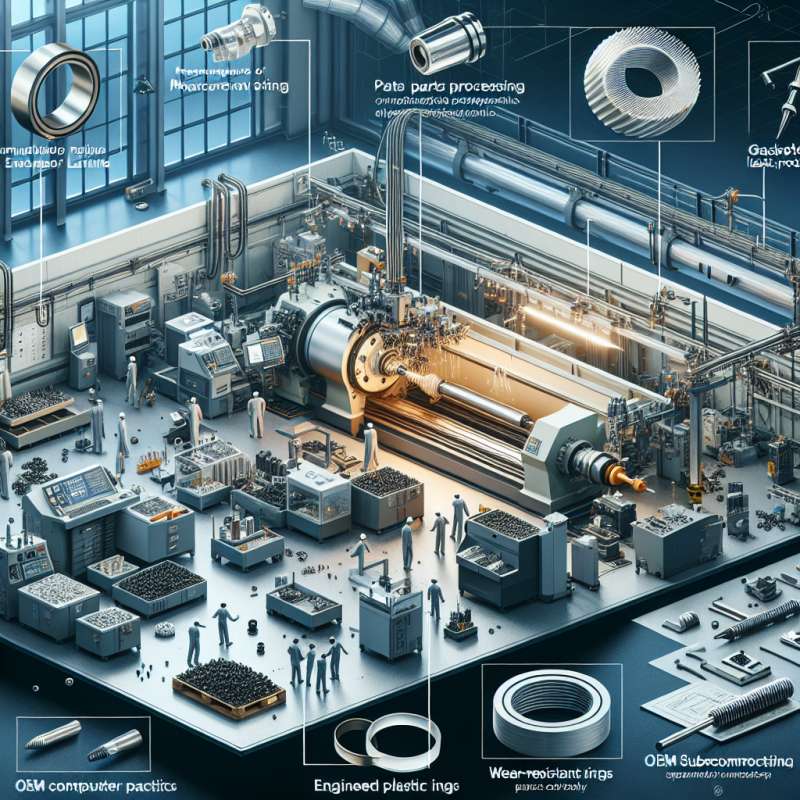

Article: With the advancement of technology and the application of fully automated manufacturing production techniques, plastic manufacturing factories are gradually moving towards a fully automated production model. In the past, plastic manufacturing typically required a large amount of manpower, but now with the widespread use of automated equipment, the manufacturing process is more efficient and precise.

The manufacturing of plastic film and fabric is an important part of plastic manufacturing factories, and fully automated production lines can greatly improve production efficiency and product quality. Additionally, the manufacturing of plastic sheets, pipes, and other products can also achieve higher levels of production through automated equipment.

In the future, with the continuous development and application of automated technology, plastic manufacturing factories will become more intelligent and efficient. Through automated production lines, factories can achieve faster production speeds, lower production costs, and improved product quality and consistency.

In this era of automation, plastic manufacturing factories will move towards a more intelligent and environmentally friendly direction, bringing more possibilities and opportunities for the production of plastic products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)