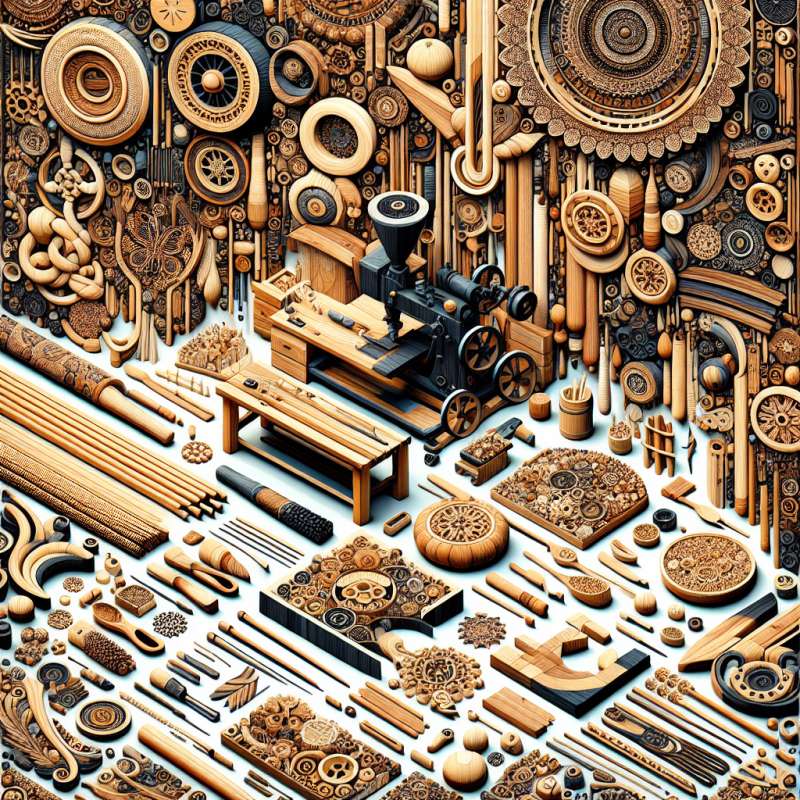

木竹是一種常見的植物,其質地堅硬且耐用,因此常被用來製造各種製品。製造木竹製品的過程需要經過多道工序。

首先,製造木竹製品的第一步是選擇優質的木竹原料。只有選擇質地優良的木竹,才能製造出高品質的製品。接著,原料需要經過加工處理,包括削皮、切割、磨光等步驟,以確保木竹表面平整且無瑕疵。

製造木竹製品的下一步是設計和製作模具。根據製品的形狀和尺寸,製作出專用的模具,以便製品能夠符合設計要求。接著,將加工處理過的木竹原料放入模具中,進行壓制和成型的過程。

最後,製造木竹製品的最後一步是進行修飾和包裝。製品需要經過修飾,包括打磨、上漆等步驟,以提升外觀質感。最後,將製品包裝好,以便運輸和銷售。

製造木竹製品的過程繁複而精細,需要嚴格控制每一個步驟,才能製造出優質的產品。

Keywords: bamboo, products, manufacturing

Title: The manufacturing process of bamboo products

Article: Bamboo is a common plant with a hard and durable texture, making it ideal for manufacturing various products. The process of making bamboo products involves multiple steps.

Firstly, the first step in making bamboo products is to select high-quality bamboo raw materials. Only by choosing high-quality bamboo can high-quality products be produced. Next, the raw materials need to undergo processing, including peeling, cutting, polishing, etc., to ensure a smooth and flawless surface.

The next step in making bamboo products is designing and making molds. According to the shape and size of the product, specialized molds are made to ensure that the product meets design requirements. The processed bamboo raw materials are then placed in the molds for pressing and shaping.

Finally, the last step in making bamboo products is finishing and packaging. The products need to be finished, including polishing, painting, etc., to enhance the appearance and quality. Finally, the products are packaged for transportation and sale.

The process of making bamboo products is complex and meticulous, requiring strict control of each step to produce high-quality products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)