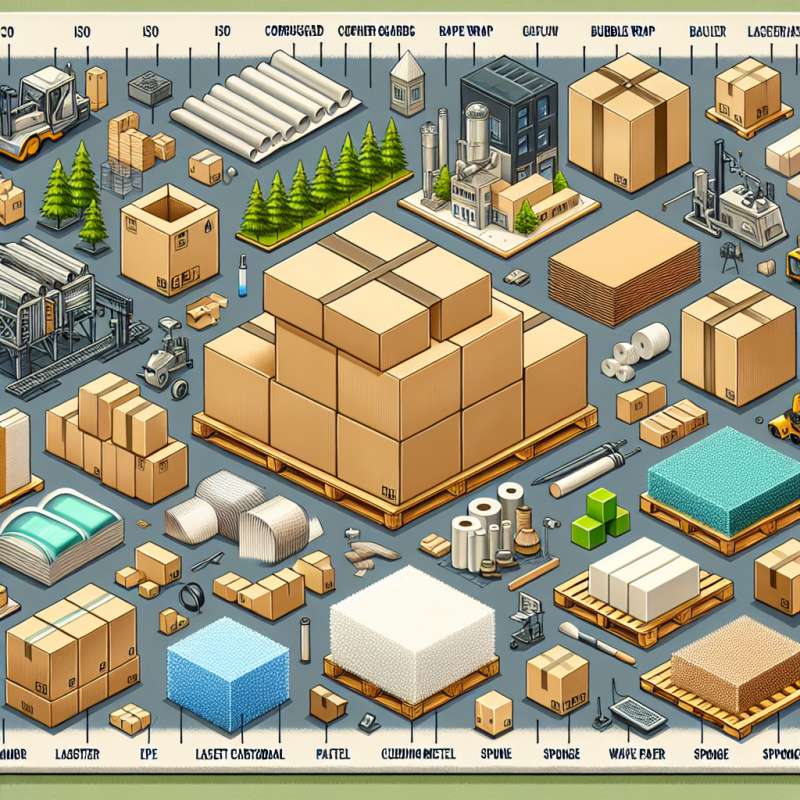

紙板製造業在近年來逐漸受到重視,隨著消費市場的不斷擴大,對紙容器的需求也逐漸增加。紙板製造廠透過一貫作業的生產流程,從原料處理到製版、印刷、貼合等工序,提供客戶高品質的紙容器產品。

設計和美工在紙板製造業中扮演著重要的角色,他們負責設計產品外觀和印刷圖案,使產品更具吸引力和競爭力。未來,隨著科技的進步,電腦輔助設計將成為紙板製造業的主流,提高生產效率和產品質量。

另外,隨著環保意識的提高,紙板製造業也將朝著環保和可持續發展的方向發展。瓦楞紙板及紙容器製造廠將會更加注重使用可再生材料和減少能源消耗,以降低對環境的影響。

總的來說,紙板製造業將會持續發展壯大,並在設計、製造和環保方面不斷創新,以滿足市場需求和保護環境。

Keywords: integrated operation, printing, design, paperboard manufacturing, future development trends

Title: Future Development Trends in Paperboard Manufacturing Industry

Article: The paperboard manufacturing industry has been gaining attention in recent years, as the demand for paper containers continues to grow with the expanding consumer market. Paperboard manufacturing plants provide high-quality paper container products to customers through an integrated operation production process, from raw material processing to plate making, printing, laminating, and other processes.

Design and graphic arts play important roles in the paperboard manufacturing industry, responsible for designing product appearances and printing patterns to make products more attractive and competitive. In the future, with the advancement of technology, computer-aided design will become mainstream in the paperboard manufacturing industry, improving production efficiency and product quality.

Furthermore, with the increasing environmental awareness, the paperboard manufacturing industry will also move towards environmental protection and sustainable development. Corrugated paperboard and paper container manufacturing plants will focus more on using renewable materials and reducing energy consumption to minimize environmental impact.

Overall, the paperboard manufacturing industry will continue to grow and innovate in design, manufacturing, and environmental protection to meet market demands and protect the environment.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)