近年來,環保議題已成為全球關注的焦點。在製造業中,如何以環保的方式生產產品成為了一個重要的課題。在這個趨勢下,PVC材料在加工設計中展現出了創新的潛力。

PVC材料是一種具有優良性能的塑料材料,其廣泛應用於各種行業。而在加工設計中,PVC材料更是能夠實現客製化的需求。客製化是一種個性化的生產模式,能夠根據客戶的需求進行量身訂製,提供更多元化的產品選擇。PVC材料的可塑性高,可以輕易地進行加工,使得客製化成為可能。

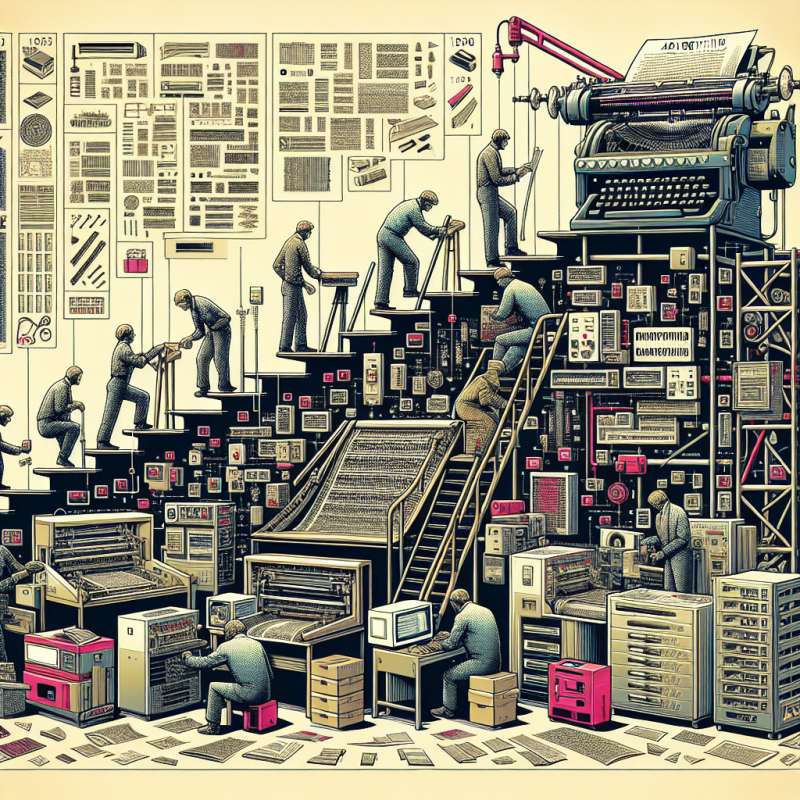

此外,PVC材料的加工能夠實現設計上的創新。加工過程中可以將PVC材料進行熔接、打印、刻印等多種技術處理,使其具有更多的功能和美感。這種設計上的創新性能夠滿足客戶對產品個性化、時尚化的需求,增加產品的附加價值。

然而,隨著環保趨勢的崛起,對於塑料材料的使用和處理也提出了更高的要求。PVC材料本身具有可回收性和可重複加工性,符合環保要求。同時,加工過程中也需要採取環保措施,如合理控制工廠的排放、選擇環保的物流方式等,減少對環境的影響。

未來,PVC材料的加工設計將更加注重環保和創新。從材料的選擇到產品的設計,環保將成為一個不可或缺的考慮因素。同時,加工工廠也需要提高生產效率,降低能源消耗和排放。隨著技術的發展,更多的環保材料可能會應用於PVC加工設計中,實現更環保、更持續發展的目標。

關鍵字: PVC, processing, materials, design, environmental protection

標題: Environmental Innovation in PVC Processing and Design

In recent years, environmental issues have become a global concern. In the manufacturing industry, producing products in an environmentally friendly manner has become an important issue. In this trend, PVC materials have shown innovative potential in processing and design.

PVC materials are plastic materials with excellent performance and are widely used in various industries. In processing and design, PVC materials can meet the demand for customization. Customization is a personalized production model that can tailor products according to customers' needs, providing more diversified product choices. PVC materials have high plasticity and can be easily processed, making customization possible.

Furthermore, PVC processing allows for innovative design. Various techniques such as welding, printing, and engraving can be applied to PVC materials during processing, enhancing their functionality and aesthetics. This design innovation meets customers' demands for personalized and fashionable products, increasing the added value of the products.

However, with the rise of the environmental trend, higher requirements have been placed on the use and treatment of plastic materials. PVC materials themselves are recyclable and can be processed repeatedly, meeting environmental requirements. At the same time, environmental protection measures need to be taken during processing, such as controlling factory emissions and choosing environmentally friendly logistics methods, to reduce environmental impact.

In the future, PVC processing and design will focus more on environmental protection and innovation. From material selection to product design, environmental protection will be an essential consideration. Processing factories also need to improve production efficiency, reduce energy consumption and emissions. With technological advancements, more environmentally friendly materials may be applied in PVC processing and design to achieve more environmentally friendly and sustainable goals.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)