近年來,隨著工業用途的不斷擴大,CNC加工OEM不銹鋼零組件的市場需求逐漸增長。不銹鋼作為一種耐腐蝕、耐高溫的材料,廣泛應用於機械器具製造中。而CNC加工技術的發展使得加工精度更高,生產效率更快,因此受到廣泛青睞。

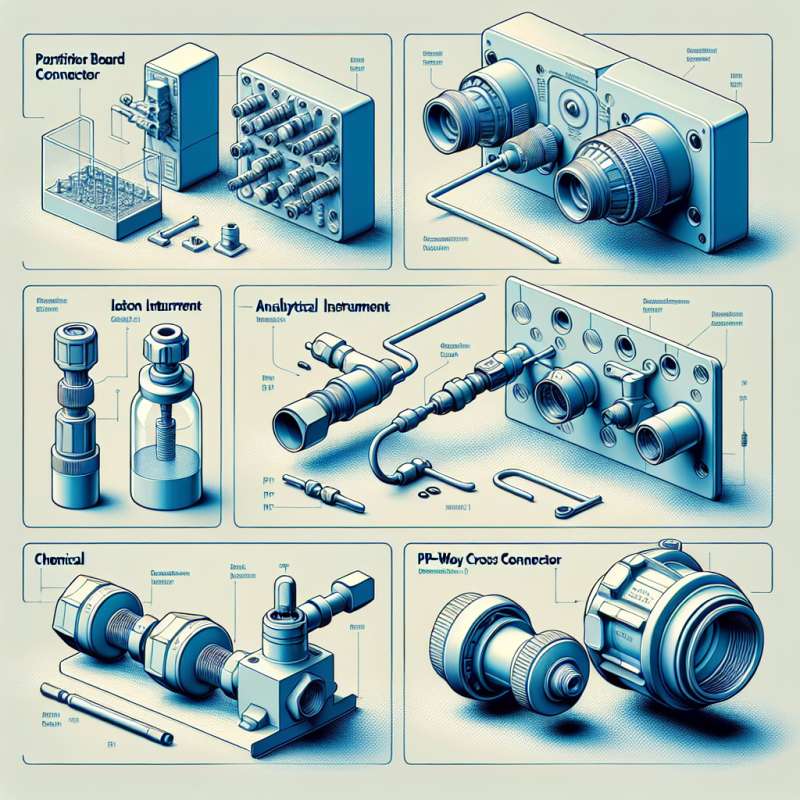

在製造過程中,CNC車床、CNC銑床等先進設備被廣泛應用,能夠實現內外徑研磨、鑽孔、SKIVING、滾齒、攻牙等多種加工工藝。同時,熱處理和表面處理技術的應用也使得不銹鋼零組件的品質得到進一步提升。

除了機械領域,不銹鋼零組件還廣泛應用於醫療、自行車等行業。在醫療領域,精密的零件加工要求尤為嚴格,而不銹鋼的材料特性正好能夠滿足這些需求。因此,代工廠商在這些領域的市場份額也在逐步擴大。

總的來說,隨著機械器具批發和基本金屬製造行業的發展,CNC加工OEM不銹鋼零組件的市場需求將會繼續增長,為相關企業帶來更多商機。

Keywords: CNC, OEM, components, stainless steel, machining, machinery

Title: Growing Market Demand for CNC Machined OEM Stainless Steel Components

Article: In recent years, with the continuous expansion of industrial applications, the market demand for CNC machined OEM stainless steel components has been gradually increasing. Stainless steel, as a corrosion-resistant and high-temperature resistant material, is widely used in the manufacturing of machinery and equipment. The development of CNC machining technology has led to higher processing accuracy and faster production efficiency, making it widely favored.

In the manufacturing process, advanced equipment such as CNC lathes and CNC milling machines are widely used, capable of various processing techniques such as internal and external diameter grinding, drilling, skiving, gear rolling, and threading. At the same time, the application of heat treatment and surface treatment technologies has further improved the quality of stainless steel components.

In addition to the machinery field, stainless steel components are also widely used in industries such as medical and bicycles. In the medical field, the precision of component machining is particularly strict, and the material characteristics of stainless steel can meet these requirements. Therefore, the market share of OEM manufacturers in these fields is gradually expanding.

Overall, with the development of machinery and basic metal manufacturing industries, the market demand for CNC machined OEM stainless steel components will continue to grow, bringing more business opportunities to related enterprises.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)