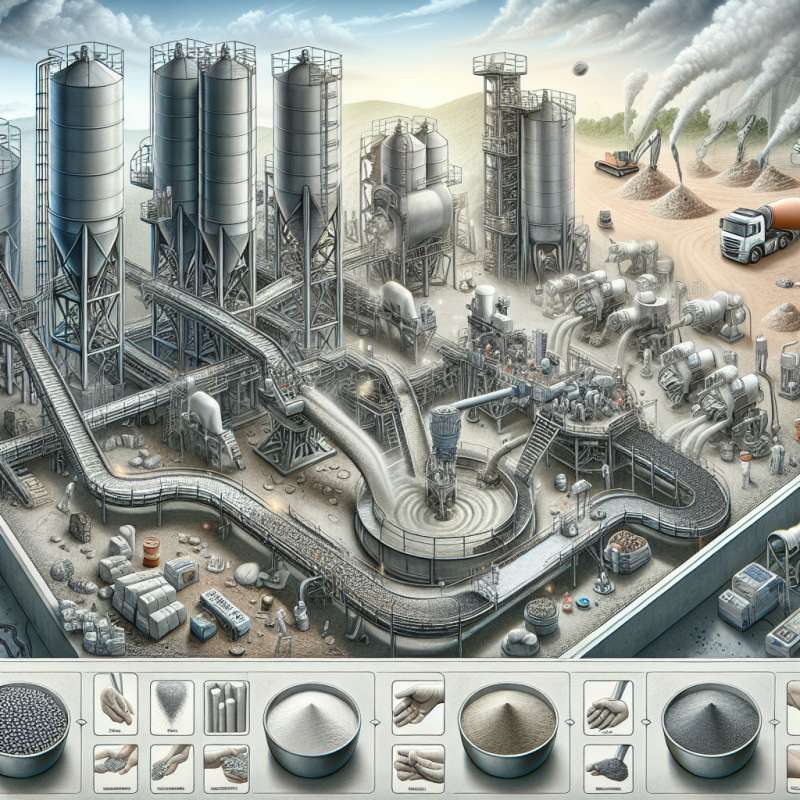

混凝土是建築工程中常用的建材之一,其品質直接關係到建築物的耐久性和安全性。在混凝土的製造過程中,混凝土配方和品質控制是至關重要的環節。

混凝土配方是指根據不同工程需求,將原料如水泥、硅酸鹽、砂、石子等按一定比例混合而成的配方。不同的混凝土配方會影響混凝土的特性,如強度、密實度等。因此,設計合理的混凝土配方對於確保混凝土的品質至關重要。

在混凝土的生產過程中,品質控制是必不可少的步驟。通過控制原料的質量、嚴格執行生產工藝、使用先進的設備等措施,可以確保混凝土的品質符合標準要求。此外,定期進行混凝土測試,如強度測試等,也是保證混凝土品質的重要手段。

對於水泥批發商來說,除了提供優質的水泥產品外,也應該重視混凝土配方和品質控制的重要性。只有確保混凝土配方合理,並加強品質控制,才能為客戶提供高品質的混凝土產品,並確保施工質量。

關鍵字: Concrete mix design, Quality control, Cement wholesale

Title: The Importance of Concrete Mix Design and Quality Control in Cement Wholesale

Article: Concrete is one of the commonly used building materials in construction projects, and its quality directly affects the durability and safety of the structures. In the manufacturing process of concrete, concrete mix design and quality control are crucial aspects.

Concrete mix design refers to the formulation of a mixture of raw materials such as cement, silicates, sand, gravel, etc., in certain proportions according to different engineering requirements. Different concrete mix designs will affect the properties of concrete, such as strength, density, etc. Therefore, designing a rational concrete mix is essential to ensure the quality of concrete.

In the production process of concrete, quality control is an indispensable step. By controlling the quality of raw materials, strictly following production processes, using advanced equipment, etc., the quality of concrete can be ensured to meet the standard requirements. In addition, conducting regular concrete tests, such as strength tests, is also an important means to ensure concrete quality.

For cement wholesalers, besides providing high-quality cement products, they should also emphasize the importance of concrete mix design and quality control. Only by ensuring reasonable concrete mix designs and strengthening quality control can high-quality concrete products be provided to customers and ensure construction quality.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)