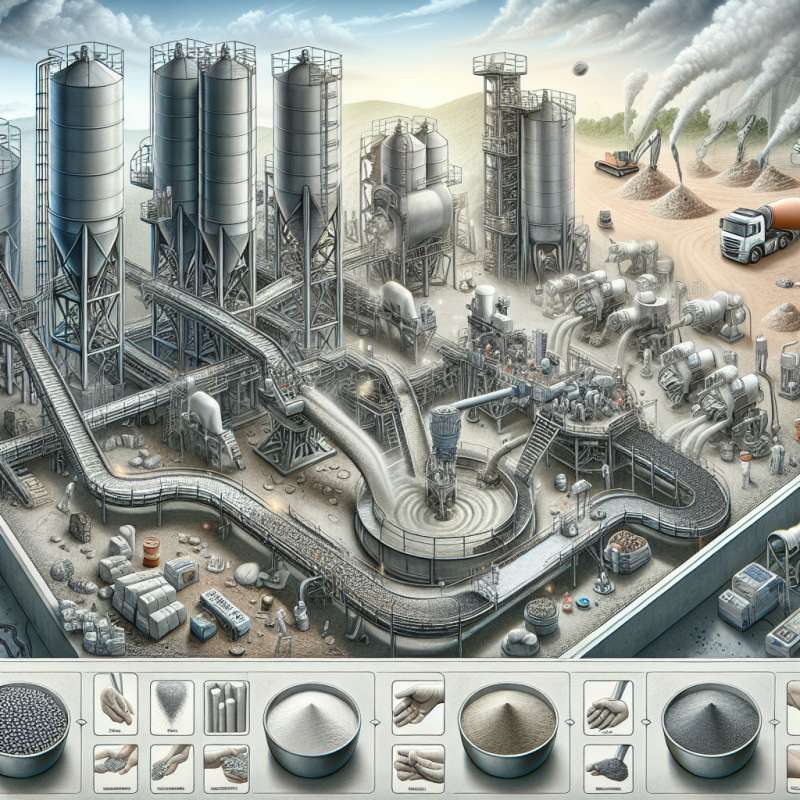

預拌混凝土是一種在工廠中生產的混凝土,它使用預先配製好的混凝土配方,通過添加水泥、硅酸鹽、砂、石子等原料進行製造。在生產過程中,品質控制是非常重要的環節,以確保最終產品符合標準。

生產工藝是影響混凝土品質的關鍵因素之一。生產工藝包括攪拌、密實、集料等步驟,每一個步驟都需要嚴格控制,以確保混凝土的組成均勻且符合配方要求。此外,設備的選擇和維護也對生產工藝起著至關重要的作用。

品質控制是確保預拌混凝土產品符合標準的關鍵。通過混凝土測試,如強度和耐久性測試,可以確保產品的品質。在施工過程中,施工質量也受到品質控制的影響,因此在施工現場和施工環境中也需要進行監控。

總的來說,預拌混凝土的生產需要嚴格控制原料的品質、遵循混凝土配方、掌握生產工藝、進行品質控制等步驟,以確保最終產品符合標準且具有良好的混凝土特性。

Keywords: Precast Concrete, Raw Materials, Quality Control

Title: Quality Control in Precast Concrete Production

Article: Precast concrete is a type of concrete produced in a factory using pre-mixed concrete formulas, with ingredients such as cement, silicates, sand, and gravel. Quality control is crucial in the production process to ensure the final product meets standards.

Production processes play a key role in determining concrete quality. Steps such as mixing, compacting, and aggregating must be carefully controlled to ensure uniform composition and adherence to the formula. Additionally, equipment selection and maintenance are vital in the production process.

Quality control is essential in ensuring precast concrete products meet standards. Concrete testing, including strength and durability tests, helps guarantee product quality. Quality control also impacts construction quality during the building process, necessitating monitoring at construction sites and environments.

In conclusion, strict control of raw material quality, adherence to concrete formulas, mastery of production processes, and quality control are essential in precast concrete production to ensure the final product meets standards and exhibits desirable concrete characteristics.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)