近年來,塑膠製品製造業的市場需求呈現穩定增長的趨勢。其中,高溫高壓板、押出模具和塑膠原料批發是這個行業中的重要關鍵字。高溫高壓板廣泛應用於太陽能板支架和隔熱隔音浪板等產品的製造中,其耐高溫高壓的特性使其在建築和工業領域中得到廣泛應用。押出模具則是製造塑膠浪板、五溝浪板和PVC浪板等產品的重要工具,其精密度和耐用性對產品質量有著決定性的影響。而塑膠原料批發則是整個塑膠製品製造業的基礎,為廠家提供各種原料以滿足生產需求。

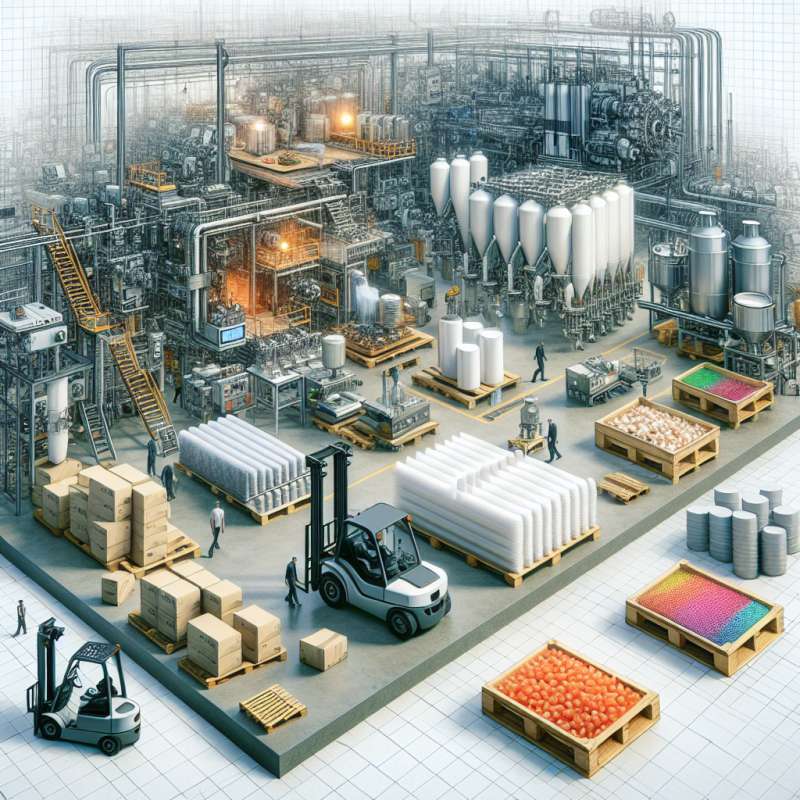

隨著環保意識的提高和科技的不斷進步,塑膠製品製造業正朝著更環保、更高效的方向發展。中古油壓機、中古造粒機和立拿機等設備的應用使生產過程更加節能環保,同時提高了生產效率。射出機、輪機和出片機等設備的使用則使產品的生產更加精密和穩定。片材平整機、發泡射出機和其他相關設備的應用也為塑膠製品製造業的發展提供了更多可能性。

總的來說,塑膠製品製造業的市場需求增長主要受到消費者對環保和品質的要求推動。隨著科技的不斷進步和生產設備的不斷更新,這個行業將會迎來更多的機遇和挑戰。

英文翻譯:

Keywords: High-temperature high-pressure board, Extrusion mold, Wholesale of plastic raw materials

Title: Market Demand Growth in the Plastic Products Manufacturing Industry

Article: In recent years, the market demand for the plastic products manufacturing industry has shown a steady growth trend. Among them, high-temperature high-pressure boards, extrusion molds, and wholesale of plastic raw materials are important keywords in this industry. High-temperature high-pressure boards are widely used in the manufacturing of products such as solar panel brackets and soundproofing wave boards, with their high-temperature and high-pressure resistance making them widely used in the construction and industrial sectors. Extrusion molds are essential tools for manufacturing products such as plastic wave boards, five-groove wave boards, and PVC wave boards, with their precision and durability having a decisive impact on product quality. Meanwhile, the wholesale of plastic raw materials is the foundation of the entire plastic products manufacturing industry, providing manufacturers with various materials to meet production needs.

With the increasing environmental awareness and continuous technological advancements, the plastic products manufacturing industry is moving towards a more environmentally friendly and efficient direction. The use of equipment such as used hydraulic presses, used granulators, and pick-and-place machines makes the production process more energy-efficient and environmentally friendly, while also improving production efficiency. The use of equipment such as injection molding machines, wheel machines, and sheet cutting machines makes product production more precise and stable. The application of equipment such as sheet flattening machines, foam injection machines, and other related equipment also provides more possibilities for the development of the plastic products manufacturing industry.

Overall, the market demand growth in the plastic products manufacturing industry is mainly driven by consumer demands for environmental protection and quality. With the continuous advancement of technology and the updating of production equipment, this industry will face more opportunities and challenges.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)