近年來,隨著科技的發展與全球市場的競爭加劇,各行各業紛紛注重提升生產力與效率。在製造業中,機械設計與製造領域更是面臨了全新的挑戰與機遇。本篇文章將探討三個非地區性但有關連的關鍵字:CNC、機械、自動化設備,並探索未來的發展趨勢。

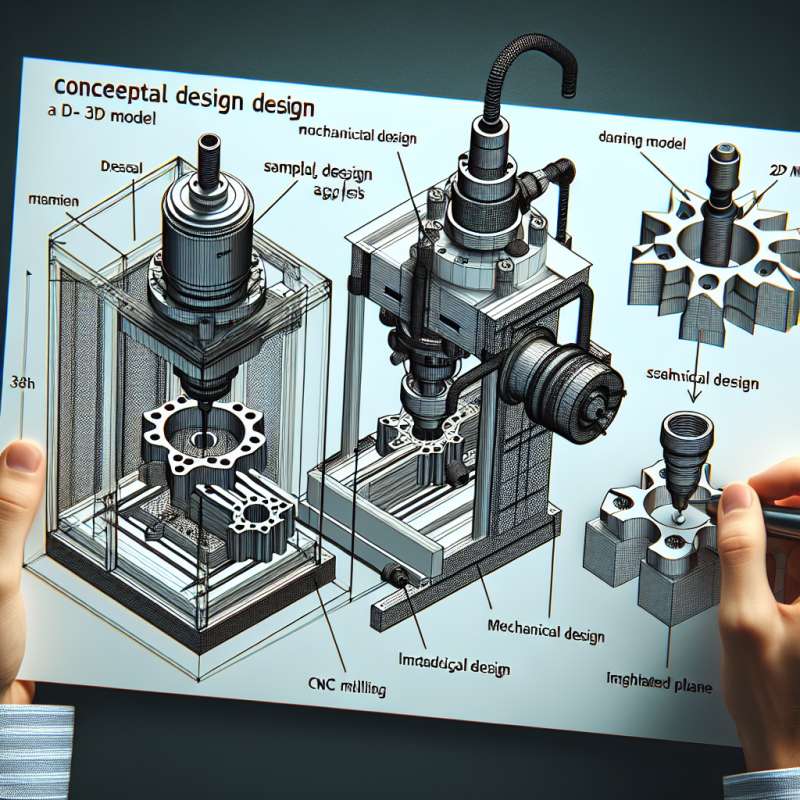

CNC(Computer Numerical Control)是一種透過電腦控制機械運動的技術。在現代製造業中,CNC已經成為了主流,因為它可以提高生產效率、降低人為錯誤。隨著數位化的發展,CNC機械設計也處於不斷創新與優化之中。例如,透過機器學習和人工智慧的應用,CNC機械可以更加智能化,自動調整加工參數,實現更高的精度和效能。

機械設計是將理論轉化為實際機械產品的過程,它涉及到許多技術領域,如材料科學、工程力學、電子技術等。在未來的發展中,機械設計將更加注重可持續發展和綠色製造。舉例而言,設計師們將致力於開發更節能且環保的機械產品,減少能源消耗和環境汙染。同時,機械設計也將更加融合數位化技術,如虛擬現實和擴增實境,以提供更直觀的設計和測試體驗。

自動化設備是指能夠自主執行一系列工序的裝置或系統。在現代製造業中,自動化已經成為了必然的趨勢。隨著人工智慧、大數據和物聯網的發展,自動化設備將更加智能化和高效率。未來,自動化設備將進一步整合CNC技術和機器學習,實現智慧工廠的概念。例如,製造業可以透過自動化設備搭載AI辨識系統,在生產過程中偵測產品的品質問題,避免不良品的生成,提高生產效率。

總結來說,CNC、機械設計和自動化設備是未來製造業發展的重要方向。隨著科技的不斷進步,這些領域將會呈現更多的創新和突破,為製造業帶來更高效率、更精確、更環保的解決方案。

關鍵字: CNC, Machine, Automation Equipment, Design, Wholesale of Unclassified Machinery and Equipment

標題: The Trend of Mechanical Design and Manufacturing in the Era of Automation and Digitization

In recent years, with the advancement of technology and the intensification of global competition, industries from all sectors have been focusing on enhancing productivity and efficiency. In the field of manufacturing, the design and production of machinery face new challenges and opportunities. This article explores three non-regional but interconnected keywords: CNC, machine, and automation equipment, and delves into their future development trends.

CNC (Computer Numerical Control) is a technology that involves controlling the movement of machinery through computer programming. In modern manufacturing, CNC has become mainstream due to its ability to improve production efficiency and reduce human errors. With the development of digitization, CNC machine design is constantly evolving and optimizing. For instance, by incorporating machine learning and artificial intelligence, CNC machinery can become more intelligent, automatically adjusting processing parameters to achieve higher precision and performance.

Machine design is the process of transforming theories into practical mechanical products, involving various technological fields such as material science, engineering mechanics, and electronics. In future developments, machine design will focus more on sustainable development and green manufacturing. For example, designers will strive to develop energy-efficient and environmentally friendly machinery products, reducing energy consumption and environmental pollution. At the same time, machine design will increasingly integrate digitization technologies such as virtual reality and augmented reality to provide a more intuitive design and testing experience.

Automation equipment refers to devices or systems that can independently perform a series of processes. In modern manufacturing, automation has become an inevitable trend. With the development of artificial intelligence, big data, and the Internet of Things, automation equipment will become more intelligent and efficient. In the future, automation equipment will further integrate CNC technology and machine learning to realize the concept of smart factories. For example, the manufacturing industry can use automation equipment equipped with AI recognition systems to detect quality issues during the production process, avoiding the generation of defective products and improving production efficiency.

In conclusion, CNC, machine design, and automation equipment are important directions for the future development of the manufacturing industry. With constant technological advancements, these fields will continue to showcase innovation and breakthroughs, providing manufacturing with solutions that are more efficient, precise, and environmentally friendly.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)