在酒精飲料製造過程中,品質控制是至關重要的一環。從原料的選擇到釀造、蒸餾、醞釀,再到瓶裝和標籤,每一個步驟都需要嚴格的品質控制來確保最終產品的優質。

首先,原料的品質直接關係到最終產品的口感和醇度。酒廠通常會選擇優質的水果或其他原料來進行釀造,以確保產品的品質。在發酵和蒸餾過程中,酵母的選擇也是至關重要的,它將直接影響酒精含量和口感。

此外,生產工藝也是影響品質的重要因素。酒廠需要擁有先進的蒸餾設備和生產工藝,以確保產量和品質的穩定。同時,品牌推廣和市場需求也是影響酒精飲料品質的因素之一,酒廠需要根據市場需求來進行飲品開發,並通過品牌推廣來提高產品的知名度和銷量。

總的來說,酒精飲料製造的品質控制是一個綜合性的過程,需要從原料的選擇到生產工藝的控制,再到市場需求的調整,都需要酒廠不斷努力和改進,才能生產出優質的產品。

Keywords: Alcoholic beverages, Manufacturing, Quality control

Title: Quality Control in the Manufacturing of Alcoholic Beverages

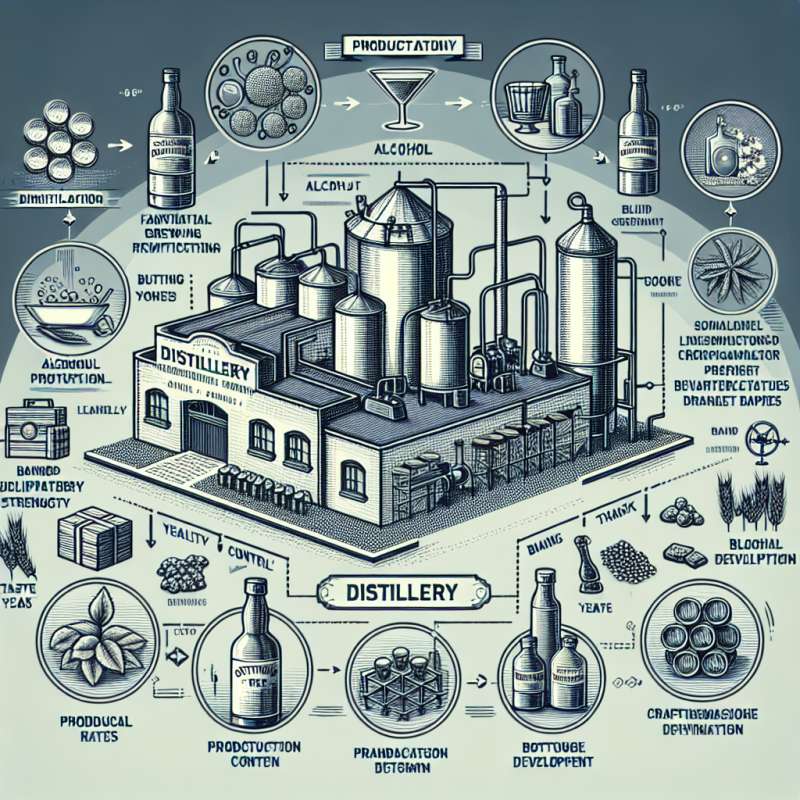

Article: In the manufacturing process of alcoholic beverages, quality control is crucial. From the selection of raw materials to brewing, distillation, fermentation, bottling, and labeling, each step requires strict quality control to ensure the high quality of the final product.

Firstly, the quality of raw materials directly affects the taste and alcohol content of the final product. Distilleries typically choose high-quality fruits or other raw materials for brewing to ensure product quality. The selection of yeast during fermentation and distillation is also crucial as it directly impacts the alcohol content and taste.

Furthermore, production processes are essential factors affecting quality. Distilleries need to have advanced distillation equipment and production processes to ensure stable production and quality. Brand promotion and market demand also influence the quality of alcoholic beverages. Distilleries need to develop beverages according to market demand and increase product awareness and sales through brand promotion.

In conclusion, quality control in the manufacturing of alcoholic beverages is a comprehensive process that requires continuous efforts and improvements from raw material selection to production process control and market demand adjustments to produce high-quality products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)