近年來,代工業正朝著全自動化的方向發展。隨著科技的進步和製造流程的優化,越來越多的代工廠商開始導入全自動化生產線,以提高生產效率和品質。

其中一個與代工業息息相關的關鍵字是刷機。刷機是指將電子設備上的軟體或韌體更換或升級的過程。在過去,刷機主要是以手動方式進行,需要操作員逐一處理。然而,隨著全自動化技術的引進,現在已經有許多代工廠商開始將刷機工序自動化,以提高生產效率並減少人為錯誤。

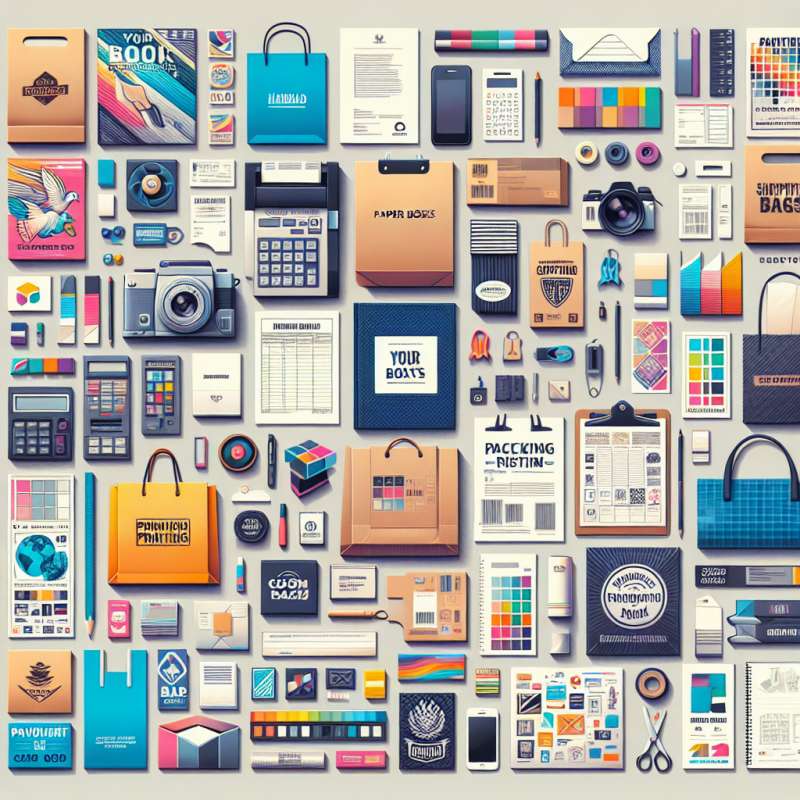

另一個與代工業相關的關鍵字是印刷品裝訂及加工。印刷品裝訂及加工是指將已印製完成的印刷品進行裝訂和加工處理,以產生最終成品。同樣地,隨著全自動化的興起,越來越多的代工廠商開始將印刷品裝訂及加工工序自動化,如自動紙張切割機、自動摺疊機等。這不僅提高了生產效率,還保證了裝訂和加工的準確性和一致性。

未來發展趨勢方面,代工業將繼續朝著全自動化的方向發展。隨著人工智能和機器學習的不斷進步,全自動化生產線將更具智能化和自主性。例如,代工廠商可以利用機器學習技術來分析和優化生產過程,以達到更高的生產效能和品質水準。

此外,隨著全自動化技術的成熟和成本的下降,越來越多的中小型代工廠商也開始導入全自動化生產線。這將使代工業更具競爭力和彈性,同時也促進了行業的發展和創新。

總之,代工業正經歷著全自動化的革命,改變了傳統的生產方式。刷機、印刷品裝訂及加工是與代工業密切相關的關鍵字,而全自動化是未來代工業發展的主要趨勢。我們可以預見,隨著科技的不斷進步和創新,代工業將實現更高效率、更高品質的全自動化生產線。

關鍵字: OEM, Fully automated, Flashing, Manual, Printing and finishing.

標題: The Future Trends of OEM Industry towards Full Automation

In recent years, the OEM industry is heading towards full automation. With advancements in technology and optimization of manufacturing processes, more and more OEM manufacturers are introducing fully automated production lines to improve productivity and quality.

One of the keywords strongly associated with the OEM industry is flashing. Flashing refers to the process of changing or upgrading software or firmware on electronic devices. In the past, flashing was mainly performed manually, requiring operators to handle it one by one. However, with the introduction of fully automated technology, many OEM manufacturers have started automating the flashing process to enhance production efficiency and reduce human errors.

Another keyword related to the OEM industry is printing and finishing. Printing and finishing involve binding and processing the printed materials to produce the final products. Similarly, with the rise of full automation, an increasing number of OEM manufacturers are automating the printing and finishing processes with automated paper cutting machines, folding machines, and more. This not only improves production efficiency but also ensures accuracy and consistency in binding and processing.

Looking towards the future trends, the OEM industry will continue to move towards full automation. With advancements in artificial intelligence and machine learning, fully automated production lines will become more intelligent and autonomous. For instance, OEM manufacturers can utilize machine learning techniques to analyze and optimize production processes for higher efficiency and quality standards.

Furthermore, as fully automated technology matures and costs decrease, more small and medium-sized OEM manufacturers are also introducing fully automated production lines. This renders the OEM industry more competitive and flexible while fostering its growth and innovation.

In conclusion, the OEM industry is undergoing a revolution towards full automation, transforming traditional manufacturing methods. Flashing and printing and finishing are keywords closely associated with the OEM industry, while full automation remains the primary trend for future OEM industry development. We can foresee that with continuous technological advancements and innovations, the OEM industry will achieve highly efficient and top-quality fully automated production lines.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)