近年來,隨著科技的不斷進步, PCB 製造及後段加工服務的市場需求也逐漸增長。 PCB 不僅可以製作單、雙面板,還可以生產多層板,甚至高達8層板的量產,以及鋁基板等各種類型的 PCB。這些 PCB 不僅在電子產品製造中扮演著重要的角色,也廣泛應用於各種領域,如通訊、醫療、汽車等。

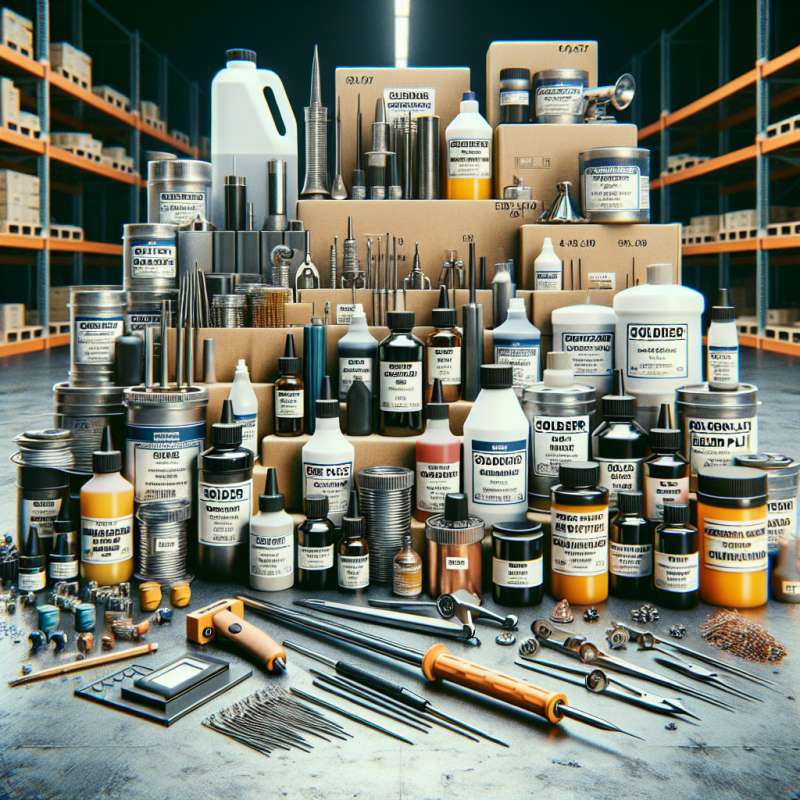

在 PCB 製造過程中, SMT 加工、插件加工、自動插件加工、打線加工等後段加工工藝也變得越來越重要。這些加工方式可以有效提高 PCB 的生產效率和品質,同時也滿足了客戶對 PCB 的不同需求。此外,組立和電子器材、電子設備的批發也成為了 PCB 製造商的一個重要業務項目。

隨著市場對高品質 PCB 的需求不斷增加, PCB 製造商需要不斷提升自身的技術水平和生產能力,以滿足客戶的需求。同時,不斷創新和開發新的 PCB 技術也是 PCB 製造商需要重視的方向之一。

English translation:

Keywords: PCB, SMT processing, multilayer board, wholesale of electronic equipment

Title: Increasing Market Demand for PCB Manufacturing and Post-Processing Services

Article: In recent years, with the continuous advancement of technology, the market demand for PCB manufacturing and post-processing services has been gradually increasing. PCBs can be produced not only as single or double-sided boards, but also as multilayer boards, with production capabilities of up to 8 layers, as well as aluminum-based PCBs and various other types. These PCBs play a crucial role not only in the manufacturing of electronic products, but also have wide applications in various fields such as communications, medical, automotive, and more.

In the PCB manufacturing process, post-processing techniques such as SMT processing, plug-in processing, automatic plug-in processing, wire bonding, and others have become increasingly important. These processing methods can effectively improve the production efficiency and quality of PCBs, while also meeting the diverse needs of customers. Additionally, assembly and wholesale of electronic equipment and devices have become important business segments for PCB manufacturers.

As the market demand for high-quality PCBs continues to increase, PCB manufacturers need to continuously enhance their technical capabilities and production capacities to meet customer requirements. At the same time, innovation and the development of new PCB technologies are also important directions for PCB manufacturers to focus on.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)