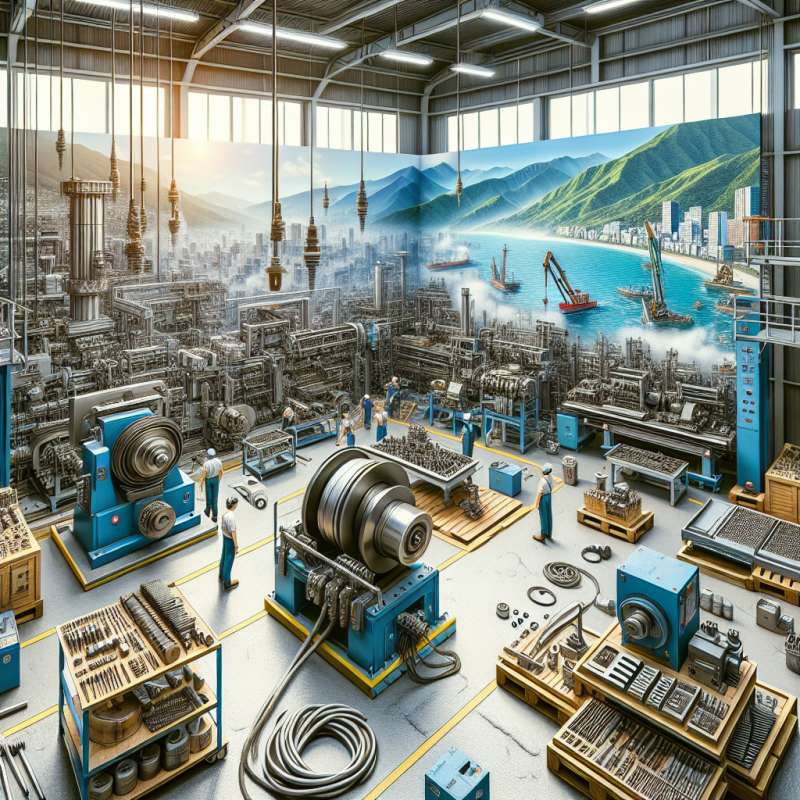

金屬加工機械在製造業中扮演著重要的角色,它們能夠將原料加工成各種形狀和尺寸的產品。然而,這些機械在長時間運轉後可能會出現故障,這時就需要進行設備維修。設備維修是確保機械正常運轉的關鍵步驟,它包括檢查零件是否磨損、潤滑油是否充足等工作。

另外,當我們購買新的金屬加工機械時,也需要進行安裝工作。安裝是確保機械能夠正確運轉的重要環節,它包括將機械組件拆卸、運輸、安裝到指定位置等步驟。在安裝過程中,需要確保每個步驟都按照操作手冊的要求進行,以免影響機械的正常運轉。

總的來說,金屬加工機械的設備維修和安裝是確保機械長期運轉的重要環節,只有做好這些工作,才能確保機械的效率和安全性。

Keywords: metal processing machinery, equipment maintenance, installation

Title: Maintenance and Installation of Metal Processing Machinery

Article: Metal processing machinery plays a crucial role in the manufacturing industry, as they are able to process raw materials into various shapes and sizes of products. However, these machines may experience malfunctions after prolonged operation, requiring equipment maintenance. Equipment maintenance is a key step in ensuring the proper operation of machinery, involving tasks such as checking for worn parts and ensuring sufficient lubrication.

Furthermore, when purchasing new metal processing machinery, installation is also necessary. Installation is an essential process to ensure the correct operation of machinery, involving steps such as disassembling machine components, transporting, and installing them in the designated location. During the installation process, it is important to follow the instructions in the operation manual for each step to avoid affecting the normal operation of the machinery.

In conclusion, equipment maintenance and installation of metal processing machinery are crucial steps in ensuring the long-term operation of machinery. Only by performing these tasks properly can the efficiency and safety of the machinery be guaranteed.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)