近年來,橡膠模壓零件和PVC管在工業用橡膠製品製造領域中扮演著重要的角色。橡膠模壓零件通常用於汽車、機械設備和電子產品等領域,其具有耐磨、耐油、耐高溫等優良性能。而PVC管則廣泛應用於建築、農業、化工等領域,具有耐腐蝕、耐壓力強等特點。

未來,隨著工業技術的不斷進步和市場需求的增加,橡膠模壓零件和PVC管的應用範圍將進一步擴大。特別是在環保意識日益提高的情況下,對於耐熱、耐腐蝕的材料需求將會增加,這將為橡膠模壓零件和PVC管的發展提供更多機遇。

因此,製造商應該加強對橡膠模壓零件和PVC管的研發,提高產品的品質和性能,滿足市場需求。同時,加強與其他行業的合作,拓展應用領域,促進產品的創新和升級,以應對未來的挑戰和機遇。

Keywords: Rubber molded parts, PVC pipes, Heat-resistant pipes

Title: Future Development Trends of Rubber Molded Parts and PVC Pipes

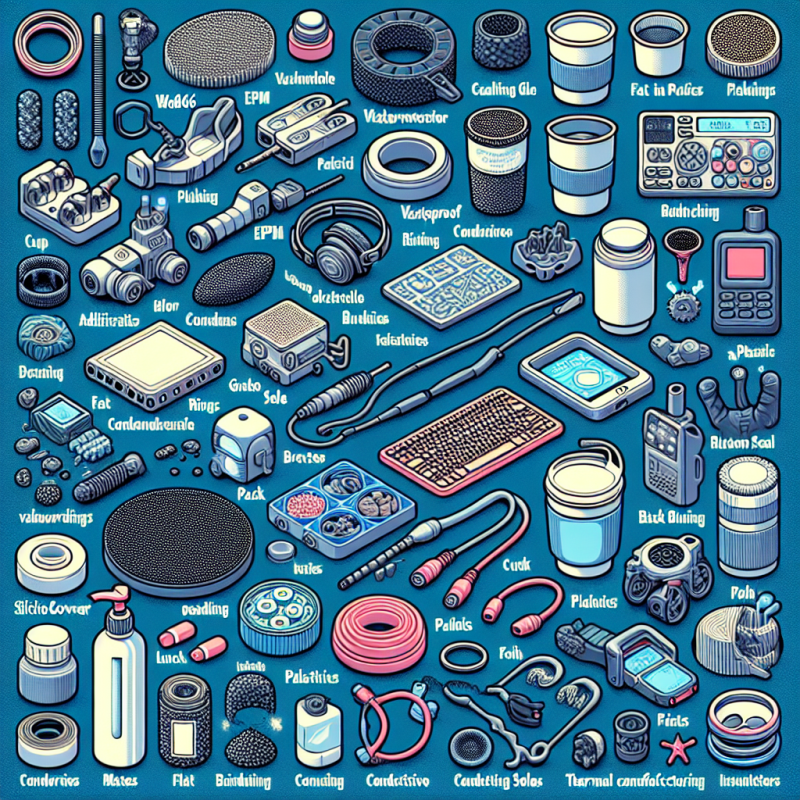

Article: In recent years, rubber molded parts and PVC pipes have played important roles in the manufacturing of industrial rubber products. Rubber molded parts are commonly used in areas such as automotive, machinery, and electronics, with excellent properties such as wear resistance, oil resistance, and high temperature resistance. PVC pipes, on the other hand, are widely used in construction, agriculture, chemical industry, and other fields, known for their corrosion resistance and high pressure resistance.

In the future, with the continuous advancement of industrial technology and increasing market demand, the application scope of rubber molded parts and PVC pipes will further expand. Particularly, with the increasing environmental awareness, the demand for materials that are heat-resistant and corrosion-resistant will rise, providing more opportunities for the development of rubber molded parts and PVC pipes.

Therefore, manufacturers should strengthen research and development of rubber molded parts and PVC pipes, improve product quality and performance to meet market demands. Additionally, enhancing collaboration with other industries, expanding application areas, promoting product innovation and upgrades will help in addressing future challenges and opportunities.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)