近年來,隨著全球供應鏈的日趨緊密和國際貿易的頻繁發展,特殊零件製造業成為不可或缺的一環。特殊零件是指那些在特定產品或設備中使用的獨特部件,常常需要進口設備和材料來製造。在這個行業中,進口設備和電子連接器(線)製造是兩個非常重要的關鍵字。

進口設備是指從其他國家引進的製造機械和設備。特殊零件製造業通常需要高精度的機器來製造各種形狀和尺寸的零件。這些進口設備能夠提供更高的生產效率和品質保證,使得製造商能夠滿足客戶對特殊零件的需求。同時,進口設備還可以促進技術交流和合作,進一步提升產業的整體水平。

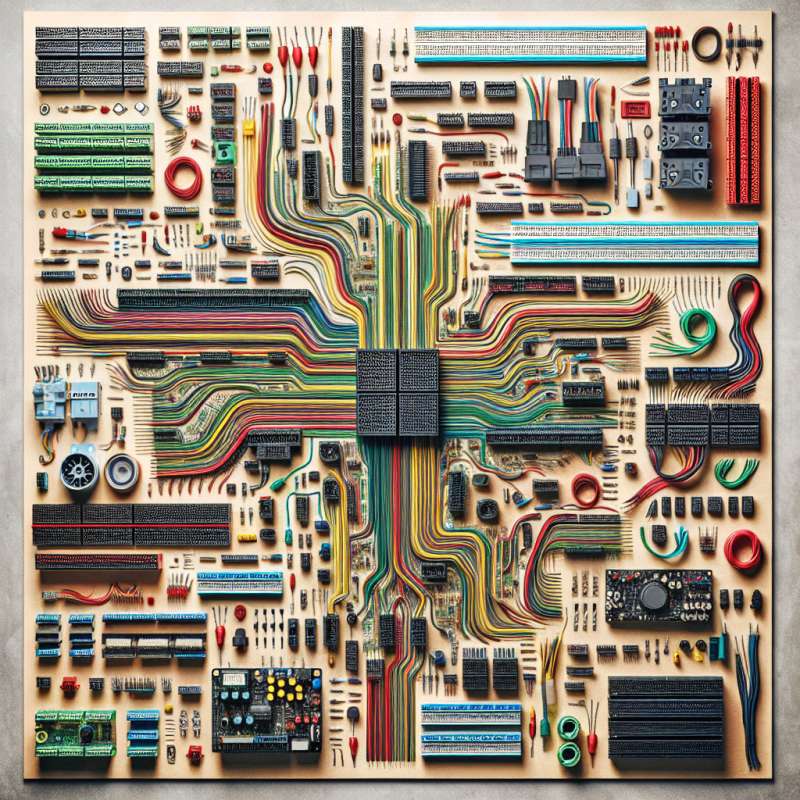

另一方面,電子連接器(線)製造是特殊零件製造業中的一個關鍵領域。隨著電子產品的不斷推陳出新和技術的不斷演進,對於高品質和高可靠性的電子連接器的需求也越來越大。這就需要製造商能夠掌握先進的生產技術和設備,以生產出符合國際標準的電子連接器。因此,電子連接器(線)製造成為特殊零件製造業中一個具有潛力和競爭力的方向。

未來,特殊零件製造業將繼續受到進口設備和電子連接器(線)製造的影響。隨著技術的進步和市場需求的變化,製造商需要不斷學習和掌握最新的製造技術和流程,以適應不斷變化的市場。在進口設備方面,製造商應該積極尋找國際合作夥伴,引進優秀的製造設備和技術,並運用自身的優勢實現自主創新。在電子連接器(線)製造方面,製造商應該注重產品品質和可靠性的提升,並根據市場需求調整產品結構和技術研發的方向。

總之,特殊零件製造業的未來發展充滿了挑戰和機遇。進口設備和電子連接器(線)製造將繼續是這個行業的重要關鍵字。製造商應該不斷學習和創新,與國際接軌,以滿足市場需求,提升競爭力。

關鍵字: Special parts, imports equipment, electronic connector (wire) manufacturing

Title: Future Trends: The Rise of Imported Equipment and Electronic Connector (Wire) Manufacturing in the Special Parts Industry

Article:

In recent years, with the increasingly close global supply chain and the frequent development of international trade, the manufacturing of special parts has become an indispensable part of the industry. Special parts refer to unique components used in specific products or equipment, often requiring imported equipment and materials for production. In this industry, imported equipment and electronic connector (wire) manufacturing are two very important keywords.

Imported equipment refers to manufacturing machinery and equipment that is brought in from other countries. The special parts manufacturing industry typically requires high-precision machines to produce various shapes and sizes of parts. These imported equipment can provide higher production efficiency and quality assurance, allowing manufacturers to meet customer demand for special parts. At the same time, imported equipment can also facilitate technological exchange and cooperation, further enhancing the overall level of the industry.

On the other hand, electronic connector (wire) manufacturing is a key aspect in the special parts manufacturing industry. With the constant emergence of new electronic products and the continuous evolution of technology, the demand for high-quality and highly reliable electronic connectors is increasing. This requires manufacturers to master advanced production techniques and equipment to produce electronic connectors that meet international standards. Therefore, electronic connector (wire) manufacturing has become a potential and competitive direction in the special parts manufacturing industry.

In the future, the special parts manufacturing industry will continue to be influenced by imported equipment and electronic connector (wire) manufacturing. With technological advancements and changes in market demand, manufacturers need to continuously learn and master the latest manufacturing techniques and processes to adapt to the ever-changing market. In terms of imported equipment, manufacturers should actively seek international partnerships, introduce excellent manufacturing equipment and technology, and utilize their own advantages to achieve independent innovation. In terms of electronic connector (wire) manufacturing, manufacturers should focus on improving product quality and reliability, and adjust product structure and technology research and development direction according to market demand.

In summary, the future development of the special parts manufacturing industry is full of challenges and opportunities. Imported equipment and electronic connector (wire) manufacturing will continue to be important keywords in this industry. Manufacturers should continuously learn and innovate, synchronize with international standards, and improve competitiveness to meet market demand.

(Keywords: Special parts, imports equipment, electronic connector (wire) manufacturing

Title: Future Trends: The Rise of Imported Equipment and Electronic Connector (Wire) Manufacturing in the Special Parts Industry

Article:

In recent years, with the increasingly close global supply chain and the frequent development of international trade, the manufacturing of special parts has become an indispensable part of the industry. Special parts refer to unique components used in specific products or equipment, often requiring imported equipment and materials for production. In this industry, imported equipment and electronic connector (wire) manufacturing are two very important keywords.

Imported equipment refers to manufacturing machinery and equipment brought in from other countries. The special parts manufacturing industry typically requires high-precision machines to produce various shapes and sizes of parts. These imported equipment can provide higher production efficiency and quality assurance, allowing manufacturers to meet customer demand for special parts. At the same time, imported equipment can also facilitate technological exchange and cooperation, further enhancing the overall level of the industry.

On the other hand, electronic connector (wire) manufacturing is a key aspect in the special parts manufacturing industry. With the constant emergence of new electronic products and the continuous evolution of technology, the demand for high-quality and highly reliable electronic connectors is increasing. This requires manufacturers to master advanced production techniques and equipment to produce electronic connectors that meet international standards. Therefore, electronic connector (wire) manufacturing has become a potential and competitive direction in the special parts manufacturing industry.

In the future, the special parts manufacturing industry will continue to be influenced by imported equipment and electronic connector (wire) manufacturing. With technological advancements and changes in market demand, manufacturers need to continuously learn and master the latest manufacturing techniques and processes to adapt to the ever-changing market. In terms of imported equipment, manufacturers should actively seek international partnerships, introduce excellent manufacturing equipment and technology, and utilize their own advantages to achieve independent innovation. In terms of electronic connector (wire) manufacturing, manufacturers should focus on improving product quality and reliability and adjust product structure and technology research and development direction according to market demand.

In summary, the future development of the special parts manufacturing industry is full of challenges and opportunities. Imported equipment and electronic connector (wire) manufacturing will continue to be important keywords in this industry. Manufacturers should continuously learn and innovate, synchronize with international standards, and improve competitiveness to meet market demand.)

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)