近年來,木材製造業逐漸走向數位化的製程,以提高生產效率及品質。傳統的木材加工方式包括鋸製和鉋製,然而隨著科技的進步,製程也會有所改變。

未來的發展趨勢之一是透過數位化技術來改善製程。利用電腦控制系統和自動化設備,可以提高生產效率,降低製造成本,並且可以生產更精確的產品。透過數據分析和監控系統,製造商可以即時掌握生產狀況,並做出適時的調整。

除了提高製程效率,未來的趨勢也會注重可持續性和環保性。木材是一個可再生的資源,因此製造商必須重視其使用過程中對環境的影響。透過採用綠色製造技術,減少浪費和碳排放,可以使製造業在未來更具競爭力。

總的來說,木材製造製程的未來趨勢是朝向數位化、自動化和環保化的方向發展。透過不斷創新和技術更新,木材製造業將會更具競爭力,同時也能為環境和社會做出更多的貢獻。

Keywords: lumber, sawing, planing, process, digitalization

Title: The Future Trends of Wood Manufacturing Process

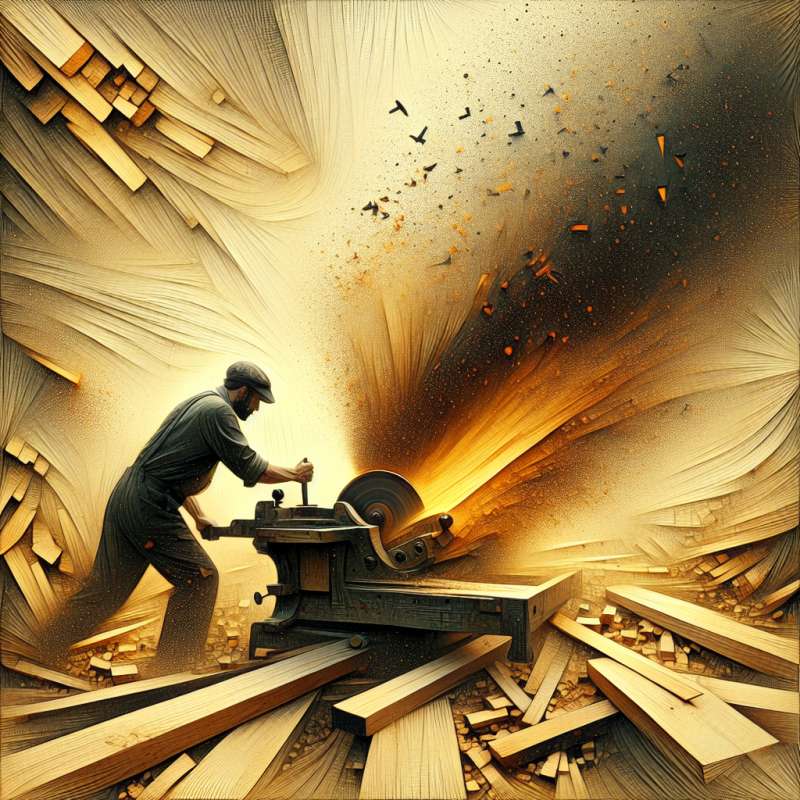

Article: In recent years, the wood manufacturing industry has been gradually moving towards digitalization of processes to improve production efficiency and quality. Traditional wood processing methods include sawing and planing, but with technological advancements, the processes will also undergo changes.

One of the future trends is to improve processes through digitalization technology. By utilizing computer control systems and automation equipment, production efficiency can be enhanced, manufacturing costs reduced, and more precise products can be produced. By using data analysis and monitoring systems, manufacturers can have real-time insights into production conditions and make timely adjustments.

In addition to improving process efficiency, future trends will also focus on sustainability and environmental friendliness. Wood is a renewable resource, so manufacturers must pay attention to its environmental impact during the use. By adopting green manufacturing techniques to reduce waste and carbon emissions, the manufacturing industry can be more competitive in the future.

In conclusion, the future trends of wood manufacturing processes are towards digitalization, automation, and environmental friendliness. Through constant innovation and technological updates, the wood manufacturing industry will become more competitive and make more contributions to the environment and society.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)