近年來,隨著電子產業的迅速發展,製程中所需的關鍵材料也扮演著愈來愈重要的角色。其中,薄膜、化學原材料和裁切技術更被視為電子製程中不可或缺的要素。

在製造電子產品時,薄膜被廣泛應用於保護膜、包裝材料及製造PC等產品。這些薄膜不僅提供保護,還可以增加產品的外觀效果和耐用性。同時,裁切技術也至關重要,因為它能將薄膜、膠帶和其他材料依照特定尺寸裁切,以滿足製程的需求。

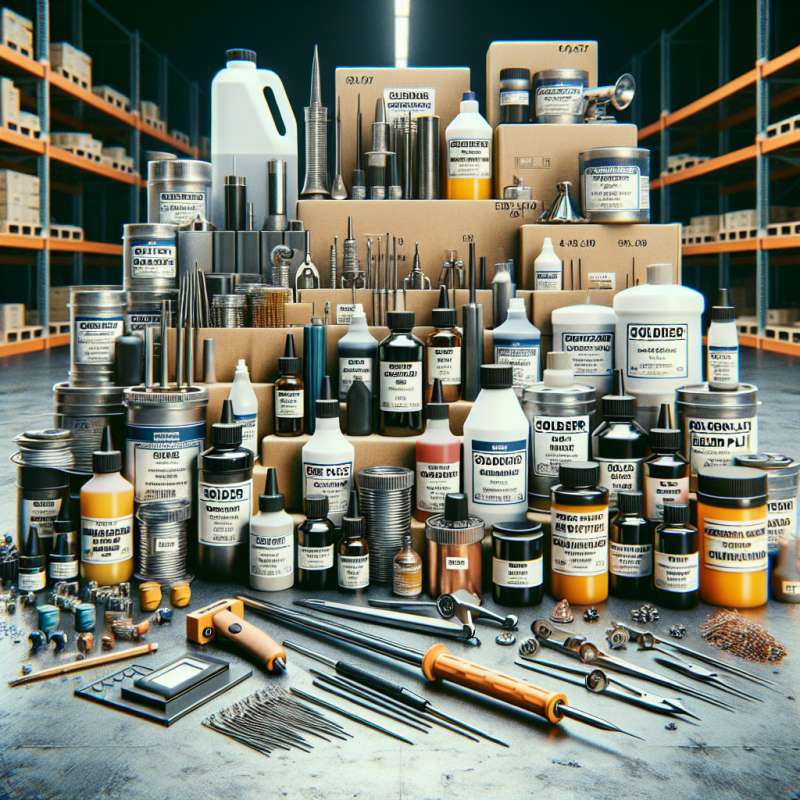

此外,電子製程中也需要大量的化學原材料。這些原材料可以用於製造雙面膠帶、耐高溫膠帶和其他工業用材料。無塵室更是在製造過程中至關重要,因為它可以確保製造出來的產品品質達到最高水準。

台北作為電子產業的中心,這些材料的需求更是日益增長。因此,代理商需要不斷地提供最新最優質的產品,以應對市場的需求。相信隨著電子產業的不斷發展,這些關鍵材料將會繼續扮演著重要的角色。

Keywords: Electronics, Cutting, Chemical Raw Materials, Film, Cleanroom

Title: Key Material Demand in Electronics Manufacturing Process

Article: In recent years, with the rapid development of the electronics industry, key materials required in the manufacturing process have become increasingly important. Among them, films, chemical raw materials, and cutting technology are considered indispensable elements in the electronics manufacturing process.

In the production of electronic products, films are widely used for protective films, packaging materials, and manufacturing of PC products. These films not only provide protection but also enhance the appearance and durability of products. Meanwhile, cutting technology is crucial as it allows materials such as films, tapes, and others to be cut to specific dimensions to meet the requirements of the process.

Furthermore, a significant amount of chemical raw materials is also needed in electronics manufacturing process. These raw materials can be used to produce double-sided tapes, high-temperature resistant tapes, and other industrial materials. Cleanrooms are especially important in the manufacturing process as they ensure the highest quality of products being manufactured.

As Taipei serves as the hub of the electronics industry, the demand for these materials is growing rapidly. Therefore, agents need to continuously provide the latest and highest quality products to meet market demands. With the continuous development of the electronics industry, these key materials are expected to continue playing crucial roles.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)