纸张是我们日常生活中不可或缺的物品之一,而纸张的质量直接关系到用户的使用体验和满意度。在纸张制造的过程中,纸浆起到至关重要的作用。纸浆的质量决定了最终纸张的质量,因此纸张生产过程中的纸浆质量控制十分重要。

纸浆是造纸机的原材料之一,它来源于纤维素材料,如木材、废纸等。不同种类的纤维素在纸浆中的比例不同,直接影响到纸张质量的好坏。在造纸机上,纸浆被加工成纸张,并在过程中经历压榨、烘干等步骤,最终形成纸张。

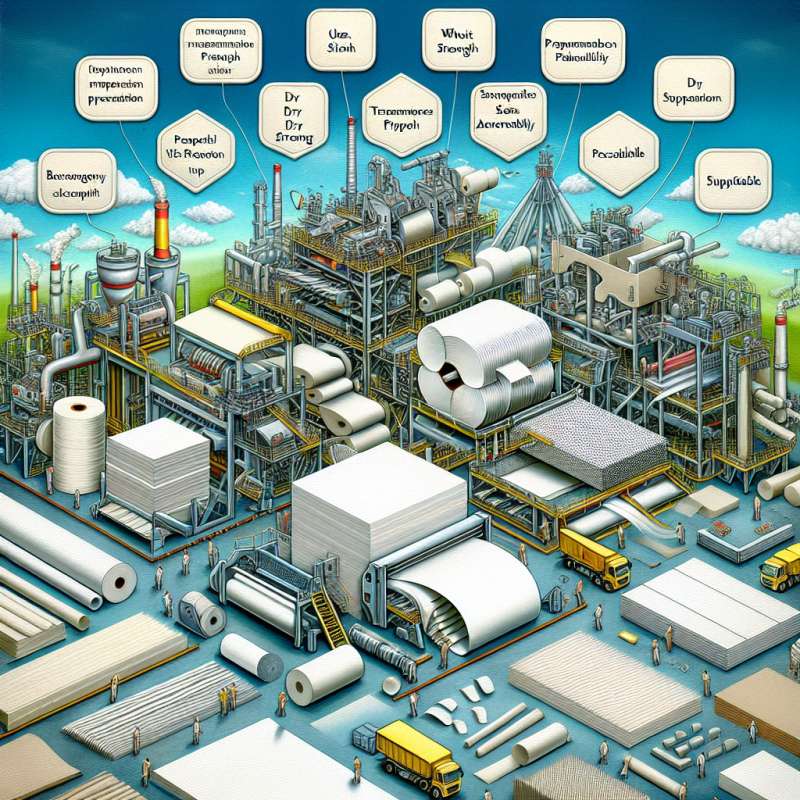

纸张的质量可以通过多个指标来评估,包括纸张厚度、湿强度、干强度、光滑度等。除了物理指标外,还有纸张通过性、透明度、白度、手感等因素也直接影响用户对纸张的评价。优质的纸张不仅要有高质量的原材料和生产工艺,还需要保证环保、可持续发展等要求。

在市场需求日益增长的背景下,纸张的生产量逐年增加,供应链也变得更加复杂。为了降低成本,提高效益,制造商们不断优化纸张生产过程,控制每一个环节的质量,并不断研究新的生产技术和材料。

纸张的用途多种多样,涵盖了书籍、报纸、包装、印刷品等多个领域。不同用途的纸张有不同的要求,因此制造商需要根据市场需求调整生产方向,灵活应对市场变化。

总的来说,纸张的质量控制是一个复杂而关键的过程,需要结合纸浆质量、制造机器、生产工艺等多个因素,以提供满足用户需求的优质纸张产品。

Keywords: pulp, paper machine, paper quality

Title: Paper Production Process and Quality Control

Article:

Paper is one of the essential items in our daily lives, and the quality of paper directly affects the user's experience and satisfaction. In the paper manufacturing process, pulp plays a crucial role. The quality of pulp determines the quality of the final paper, so quality control of pulp in the paper production process is vital.

Pulp is one of the raw materials for paper machines, derived from fibrous materials such as wood and waste paper. The proportion of different types of cellulose in pulp directly impacts the quality of paper. On the paper machine, pulp is processed into paper and undergoes processes such as pressing and drying, ultimately forming paper.

The quality of paper can be assessed by various indicators, including thickness, wet strength, dry strength, smoothness, etc. In addition to physical indicators, factors such as permeability, transparency, whiteness, and feel also directly affect the user's evaluation of paper. High-quality paper not only requires high-quality raw materials and production processes but also needs to meet requirements for environmental protection, sustainable development, etc.

Against the backdrop of growing market demand, the production volume of paper is increasing year by year, and the supply chain is becoming more complex. To reduce costs and improve efficiency, manufacturers continuously optimize the paper production process, control the quality of each link, and continually research new production technologies and materials.

Paper has a wide range of uses, including books, newspapers, packaging, printed materials, among others. Papers for different purposes have different requirements, so manufacturers need to adjust their production direction according to market demand and adapt flexibly to market changes.

In conclusion, quality control of paper is a complex and crucial process that requires the combination of pulp quality, manufacturing machinery, production processes, and other factors to provide high-quality paper products that meet user needs.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)