近年來,隨著科技的快速進步,印刷電路板製造領域也迎來了新的發展趨勢。自動化加工技術的應用已經成為製造過程中不可或缺的一環,大大提高了生產效率和品質。

SMD(表面黏著元件)加工技術作為印刷電路板製造的重要組成部分,能夠實現元件更加緊湊的布局,提高產品性能和功能。隨著人工智能(AI)的應用,製造過程將會更加智能化和精準化,幫助製造商更好地滿足市場需求。

在點膠機技術的進步下,印刷電路板製造過程中的點膠工作將更加精確和高效。傳統的臥式製程正在逐漸被立式製程取代,使得製造空間得到更好的利用並提高了產品的生產效率。

總的來說,未來印刷電路板製造將會越來越智能化、自動化和精準化,從而提高整個產業的競爭力和發展空間。

Keyword: Automation processing, SMD processing, Surface adhesion

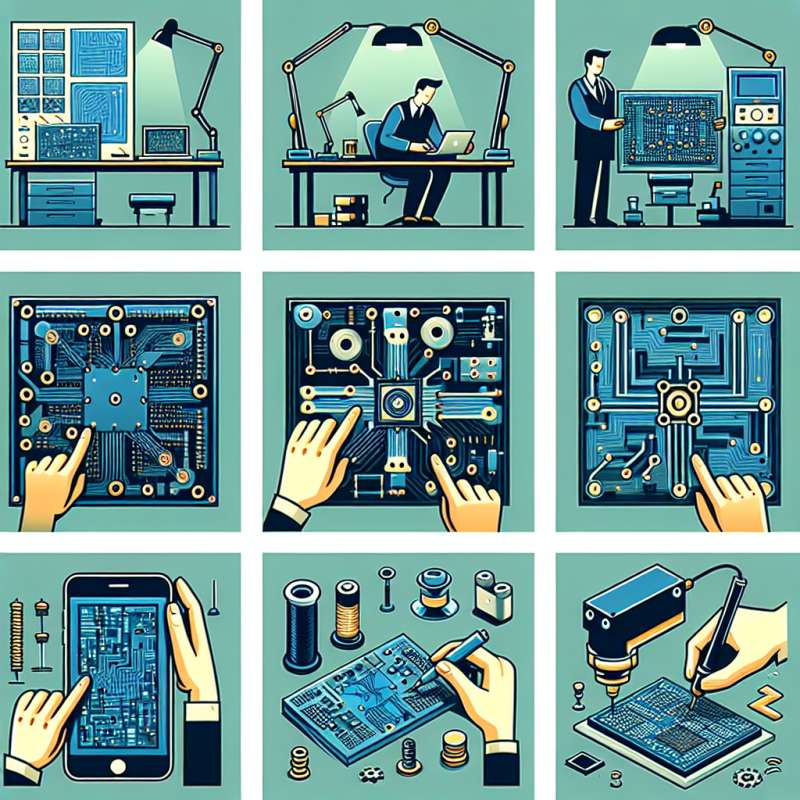

Title: Future Trends in Printed Circuit Board Manufacturing

Article: In recent years, with the rapid advancement of technology, the field of printed circuit board manufacturing has also seen new trends in development. The application of automation processing technology has become an indispensable part of the manufacturing process, greatly improving production efficiency and quality.

SMD (Surface Mount Device) processing technology, as an important component of printed circuit board manufacturing, can achieve a more compact layout of components, improving product performance and functionality. With the application of Artificial Intelligence (AI), the manufacturing process will become more intelligent and precise, helping manufacturers better meet market demands.

With the advancement of dispensing machine technology, the dispensing work in the process of printed circuit board manufacturing will be more precise and efficient. Traditional horizontal processes are gradually being replaced by vertical processes, making better use of manufacturing space and improving the production efficiency of products.

In conclusion, the future of printed circuit board manufacturing will become more intelligent, automated, and precise, thus enhancing the competitiveness and development potential of the entire industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)