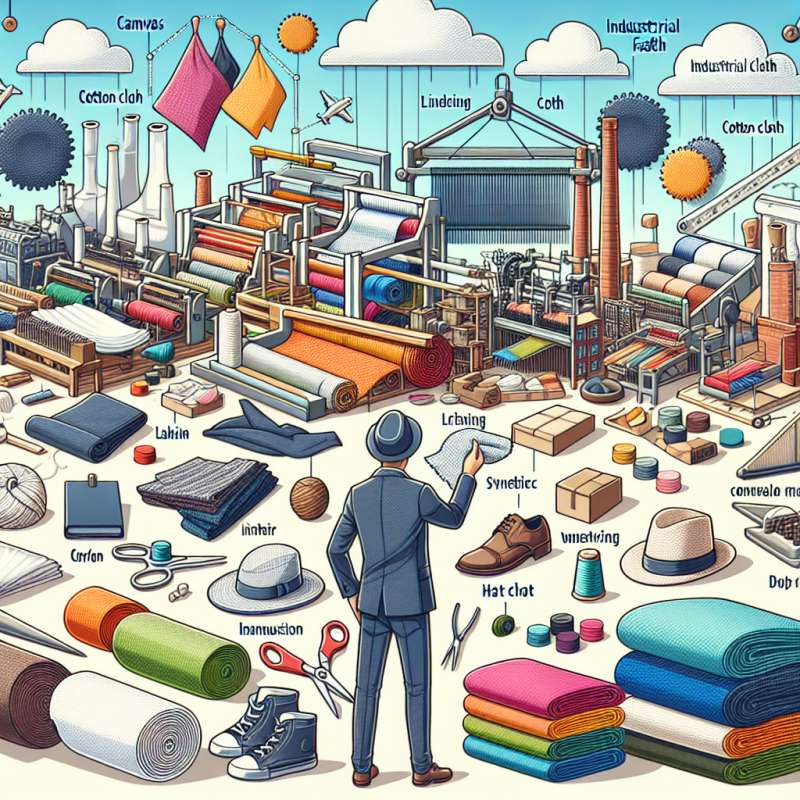

在現代化的製造業中,人造纖維是一種被廣泛應用的材料。人造纖維是透過化學方法合成的纖維,質地柔軟且有著良好的耐磨性和耐久性,因此廣泛應用於製造衣物、家具、車輛內飾等領域。

製造人造纖維的過程需要一系列的化學反應和機械製造,其中梭織布是一種常見的人造纖維應用。梭織布是利用機械經過梭織的方式編織而成,具有良好的透氣性和舒適度。

在製造梭織布的過程中,人造纖維經過染色、拉絲、織造等多道工序,最終形成一塊塊的布料。製造過程中需要嚴格的品質控制和檢驗,以確保最終產品的質量符合標準。

人造纖維的應用領域不斷擴大,越來越多的製造廠商開始使用這種環保且性能優越的材料。梭織布作為人造纖維的一種應用形式,在各個行業都有著廣泛的應用,為不同產品帶來更好的性能和舒適度。

Keywords: artificial fiber, woven fabric, manufacturing

Title: The manufacturing process of woven fabric and the application of artificial fibers

Article: In the modern manufacturing industry, artificial fibers are widely used materials. Artificial fibers are fibers synthesized through chemical methods, with soft texture and good wear resistance and durability, so they are widely used in the manufacturing of clothing, furniture, vehicle interiors and other fields.

The manufacturing process of artificial fibers requires a series of chemical reactions and mechanical manufacturing, among which woven fabric is a common application of artificial fibers. Woven fabric is woven by machines through the shuttle weaving process, with good breathability and comfort.

In the process of manufacturing woven fabric, artificial fibers undergo processes such as dyeing, drawing, weaving, etc., and finally form pieces of fabric. Strict quality control and inspection are required in the manufacturing process to ensure that the quality of the final product meets standards.

The application of artificial fibers is expanding, and more and more manufacturers are beginning to use this environmentally friendly and high-performance material. Woven fabric, as a form of application of artificial fibers, has a wide range of applications in various industries, bringing better performance and comfort to different products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)