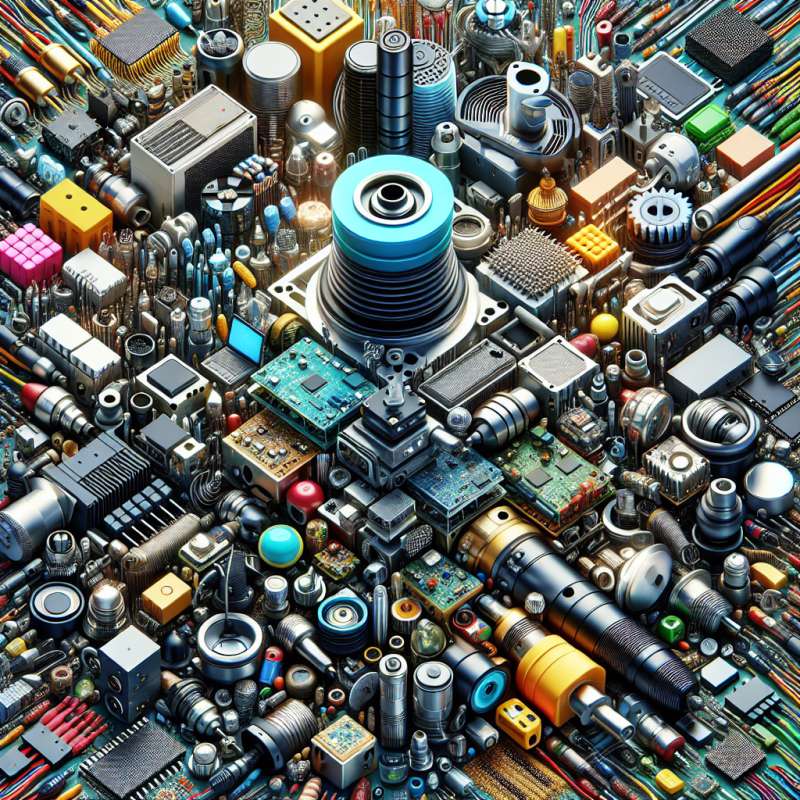

自製和自我定制已成為現代社會中普遍的趨勢。DIY (Do-It-Yourself)文化已經悄悄地滲透到不同領域,而其中一個重要的領域就是機械設備製造。近年來,隨著CNC (Computer Numerical Control,數值控制) 技術的發展,DIY市場中的機械設備DIY的趨勢不斷增加,尤其是在金屬加工、日本的CNC研發和精密零件製造方面。

DIY愛好者常常需要製造各種不同形狀和尺寸的金屬零件,以滿足自己的需求。這就需要高精度且可控制的機械設備,其中CNC是一個非常重要的技術。CNC技術能夠通過編程直接控制機械設備,使其能夠準確地製作出複雜的零件。因此,CNC機械設備在DIY市場中變得非常受歡迎。

而在CNC技術的推動下,日本成為全球CNC研發的中心之一。日本的制造業一直以來都以精密工藝聞名,而CNC技術為其提供了更高效和更精確的生產方式。日本的CNC研發團隊致力於改進CNC機械設備的性能和功能,以滿足市場需求。他們在控制系統、刀具和零件製造等方面不斷進行創新,提高了CNC機械設備的加工能力和產品的精度。

而金屬加工作為DIY市場的一個重要領域,隨著CNC技術的普及,金屬加工變得更加容易和高效。DIY愛好者們現在能夠使用CNC機械設備來製造各種精密的金屬零件,從而實現他們的創意和想法。這不僅為DIY市場帶來了更多的可能性,也促使了金屬加工行業的發展。

未來的趨勢顯示,未分類的其他專用機械設備製造、光學儀器及設備製造和電腦週邊設備製造也會成為DIY市場的重要組成部分。隨著更多DIY愛好者的加入和對個性化產品的需求不斷增加,這些設備的需求也將快速增長。

總之,DIY市場中的機械設備DIY趨勢不斷增加,尤其是在金屬加工、日本的CNC研發和精密零件製造方面。CNC技術的發展為DIY愛好者提供了更高效和更精確的製造方式,而日本的CNC研發團隊則不斷改進CNC機械設備的性能和功能。隨著未分類專用機械設備製造、光學儀器及設備製造和電腦週邊設備製造等領域的發展,DIY市場將呈現更多可能性和潛力。

關鍵字: DIY, CNC, R&D, metal, processing, Japan, precision, parts, miscellaneous specialized machinery manufacturing, miscellaneous optical instrument and equipment manufacturing, miscellaneous computer peripheral equipment manufacturing

標題: Japanese CNC R&D and Metal Processing Trends in the DIY Market

DIY and self-customization have become prevalent trends in modern society. The DIY (Do-It-Yourself) culture has quietly permeated various fields, and one important area is the manufacturing of mechanical equipment. In recent years, with the development of Computer Numerical Control (CNC) technology, the trend of DIY in the mechanical equipment market has been increasing, especially in the areas of metal processing, Japanese CNC R&D, and precision parts manufacturing.

DIY enthusiasts often need to manufacture various shapes and sizes of metal parts to meet their needs. This requires high precision and controllable mechanical equipment, with CNC being a crucial technology. CNC technology allows for direct control of mechanical equipment through programming, enabling the accurate production of complex parts. Therefore, CNC mechanical equipment has become highly popular in the DIY market.

Driven by CNC technology, Japan has become one of the centers for CNC research and development worldwide. Japan's manufacturing industry has been renowned for its precision craftsmanship, and CNC technology provides a more efficient and precise production approach. Japanese CNC research and development teams are dedicated to improving the performance and functionality of CNC mechanical equipment to meet market demands. They continuously innovate in control systems, tooling, and parts manufacturing, enhancing the processing capabilities and precision of CNC mechanical equipment.

Metal processing, as an essential area in the DIY market, has become easier and more efficient with the widespread adoption of CNC technology. DIY enthusiasts can now use CNC mechanical equipment to create various precision metal parts, realizing their creativity and ideas. This not only brings more possibilities to the DIY market but also drives the development of the metal processing industry.

Future trends indicate that miscellaneous specialized machinery manufacturing, miscellaneous optical instrument and equipment manufacturing, and miscellaneous computer peripheral equipment manufacturing will also become integral parts of the DIY market. With more DIY enthusiasts joining and the increasing demand for personalized products, the demand for these equipment will rapidly grow.

In conclusion, the trend of DIY in the mechanical equipment market, especially in the areas of metal processing, Japanese CNC R&D, and precision parts manufacturing, is continuously increasing. The development of CNC technology provides DIY enthusiasts with more efficient and precise manufacturing methods, while Japanese CNC research and development teams continuously improve the performance and functionality of CNC mechanical equipment. With the development of miscellaneous specialized machinery manufacturing, miscellaneous optical instrument and equipment manufacturing, and miscellaneous computer peripheral equipment manufacturing, the DIY market will present more possibilities and potential.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)