近年來,隨著科技的進步和創新的應用,數位化製造技術正逐漸成為工廠生產中的重要趨勢。在製造過程中,CNC(電腦數控)技術被廣泛應用,可以實現精密控制和高效率生產。控制系統的自動化程度也在不斷提高,透過智能化的機器人和感測器,可以實現更高水準的生產效率和產品品質。

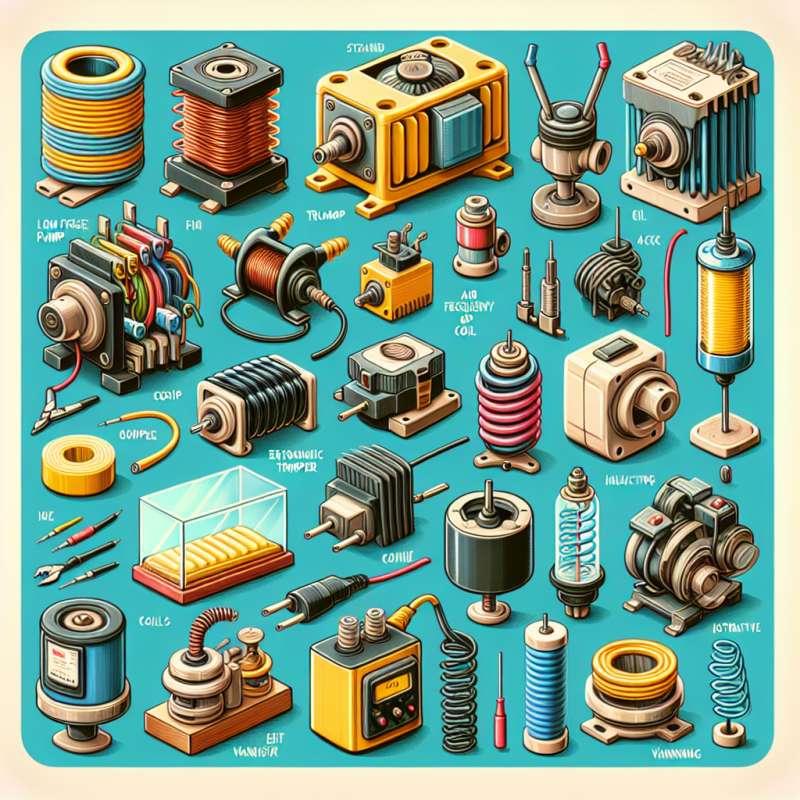

在精密製造領域,精密加工技術已經達到非常高的水準,甚至可以實現微納米級的加工精度。同時,電力用變壓器製造也在不斷採用最新的數位化製造技術,提高工廠生產效率和產品質量。

未來,數位化製造技術將持續進步和發展,例如更智能化的CNC系統、更高效率的控制系統、更靈活的製造流程等。透過創新技術的應用,工廠生產將變得更加靈活和高效,同時產品的精密度和品質也將不斷提升。

關鍵字: CNC, Control, Innovation, Precision, Transformer Manufacturing for Electrical Power

Title: Future Trends of Digital Manufacturing Technology

Article: In recent years, with advances in technology and innovative applications, digital manufacturing technology is becoming an important trend in factory production. In the manufacturing process, CNC (Computer Numerical Control) technology is widely used to achieve precise control and efficient production. The level of automation in control systems is also continuously improving, with the use of intelligent robots and sensors to achieve higher levels of production efficiency and product quality.

In the field of precision manufacturing, precision machining technology has reached a very high level, even achieving micron-level machining accuracy. At the same time, transformer manufacturing for electrical power is also adopting the latest digital manufacturing technology to improve factory production efficiency and product quality.

In the future, digital manufacturing technology will continue to progress and develop, such as more intelligent CNC systems, more efficient control systems, and more flexible manufacturing processes. Through the application of innovative technologies, factory production will become more flexible and efficient, while the precision and quality of products will continue to improve.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)