隨著科技的不斷進步,超音波加工在塑膠五金機械設備製造領域中發揮著越來越重要的作用。這種高效率、無污染的加工方式,已成為製造業界的一大趨勢和引領未來發展的關鍵。

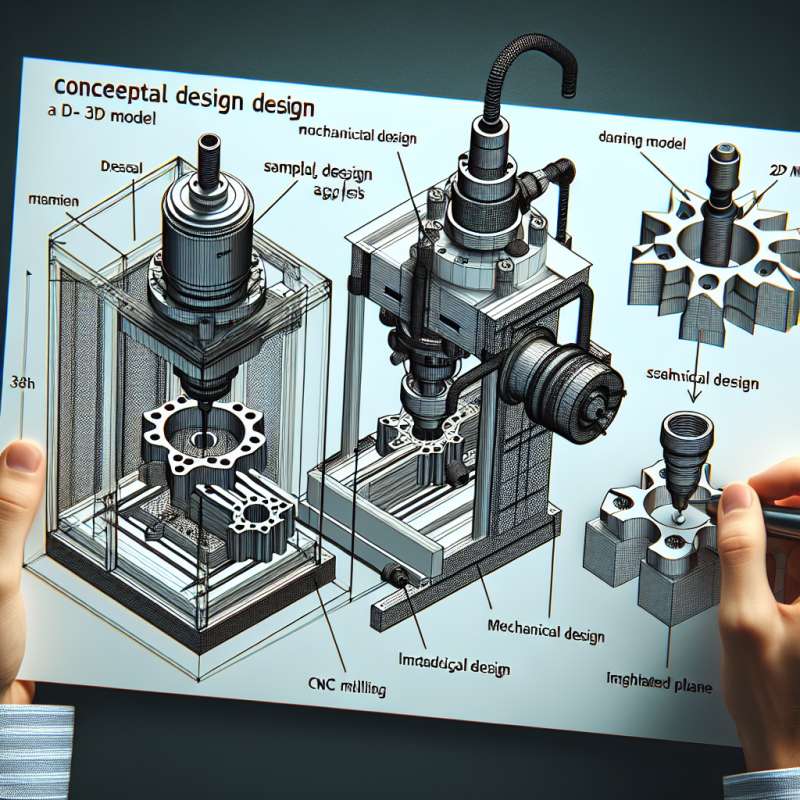

超音波加工技術是指利用超音波振動的能量來進行物料加工和塑膠金屬的焊接。透過超音波的震盪作用,將機械設備所需的螺絲、螺帽、鉚釘等五金產品與塑膠材料快速、精準地結合。這種加工方式具有許多優點,例如高效率、低能耗、無污染和精確度高等,已經被廣泛應用於各個領域。

塑膠五金機械設備批發行業對超音波加工的需求越來越大。隨著市場對塑膠五金產品的需求不斷增加,相應的加工設備也需要不斷升級和改進。超音波加工的高效率和精確度,使得製造商能夠提供更優質的產品,滿足市場需求。

未來,超音波加工技術在塑膠五金機械設備製造領域將繼續發展壯大。首先,隨著科技的進步,超音波加工設備將變得更加智能化和自動化。這將進一步提高生產效率和品質,減少人工成本。其次,超音波加工技術有著廣闊的應用範圍,不僅僅局限於塑膠五金製造領域。它也可以應用於醫療、汽車、航空航天等行業,推動這些領域的發展。

總之,超音波加工對塑膠五金機械設備製造領域具有重要的影響力和發展潛力。應該加大對超音波加工技術的研發和應用力度,進一步提高產品品質和競爭力。這將促進塑膠五金機械設備行業的發展,帶來更多商機和利益。

關鍵字: Ultrasonic, machining, plastic, hardware, machinery equipment

Title: The Future Development Trend of Ultrasonic Machining in Plastic Hardware Machinery Equipment

Article:

With the continuous advancement of technology, ultrasonic machining plays an increasingly important role in the manufacturing of plastic hardware machinery equipment. This efficient and non-polluting processing method has become a major trend in the industry, leading the way for future development.

Ultrasonic machining technology refers to the use of the energy generated by ultrasonic vibration to process materials and weld plastic and metal. Through the oscillation of ultrasonic waves, hardware products such as screws, nuts, and rivets, which are needed for machinery equipment, are quickly and accurately joined with plastic materials. This processing method has many advantages, such as high efficiency, low energy consumption, pollution-free, and high precision, and has been widely applied in various fields.

The demand for ultrasonic machining in the wholesale industry of plastic hardware machinery equipment is growing. With the increasing market demand for plastic hardware products, corresponding processing equipment needs to be constantly upgraded and improved. The high efficiency and precision of ultrasonic machining enable manufacturers to provide higher quality products to meet market demands.

In the future, ultrasonic machining technology will continue to develop and grow in the manufacturing of plastic hardware machinery equipment. Firstly, with technological advancements, ultrasonic machining equipment will become more intelligent and automated. This will further improve production efficiency and quality while reducing labor costs. Secondly, ultrasonic machining technology has a wide range of applications, not only limited to the manufacturing of plastic hardware. It can also be applied in industries such as medical, automotive, and aerospace, driving the development of these fields.

In conclusion, ultrasonic machining has significant influence and development potential in the manufacturing of plastic hardware machinery equipment. Efforts should be made to enhance research and application of ultrasonic machining technology to improve product quality and competitiveness. This will promote the development of the plastic hardware machinery equipment industry, bringing more business opportunities and benefits.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)