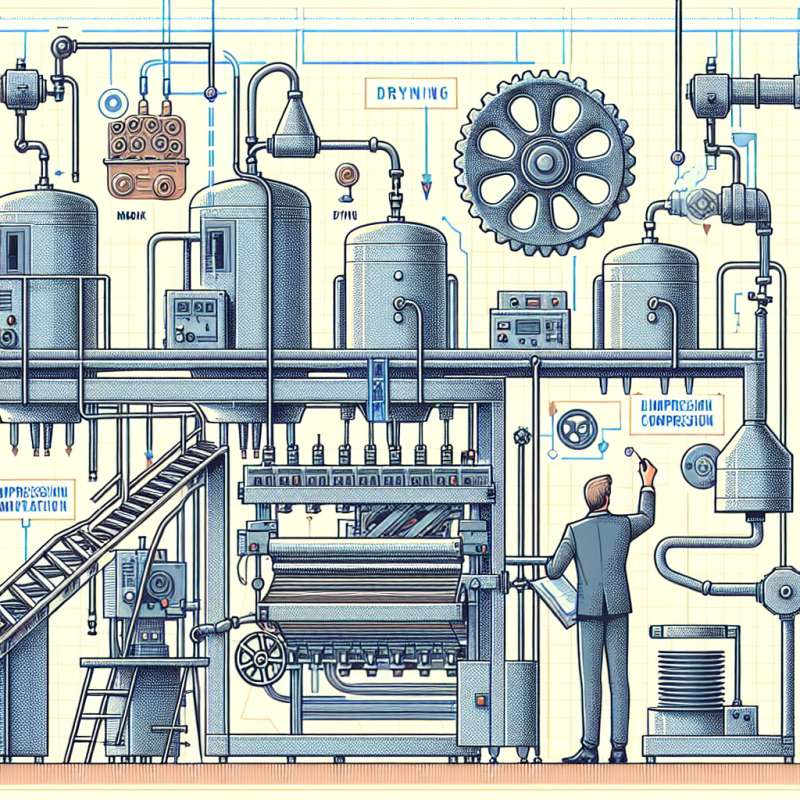

射出模真空系統是塑膠模具射出成型過程中重要的補充工具。機械助力幫浦和真空泵浦作為射出模真空系統中的核心部件,扮演著關鍵的角色。本文將介紹機械助力幫浦和真空泵浦的原理及其在射出模真空系統中的應用,並探討未來的發展趨勢。

機械助力幫浦是一種利用機械力輸出來增強流體壓力的裝置。在射出模真空系統中,機械助力幫浦可以提供更高的真空度和更穩定的運行效果,確保模具中的塑膠料充分填充。同時,它還可以降低成本,提高生產效率。機械助力幫浦的未來發展趨勢是更加節能高效,並在自動化生產中發揮更大的作用。

真空泵浦是一種利用真空技術將氣體抽出的設備。在射出模真空系統中,真空泵浦通過抽出模具中的空氣和其他不純物質,創造一個真空環境,以促進塑膠料的流動和成型。真空泵浦的選擇和使用直接影響著射出模的質量和生產效率。未來,真空泵浦將朝著更高效、更穩定和更智能化的方向發展,以符合不斷提升的產品品質和效率要求。

隨著製造業的發展,射出模真空系統的需求正在不斷增加。為了滿足市場需求,售後服務也變得非常重要。售後服務包括對機械助力幫浦和真空泵浦的維修、保養和技術支持等。提供優質的售後服務可以幫助客戶更好地使用和維護設備,延長設備的使用壽命,提高生產效率。

總結來說,機械助力幫浦和真空泵浦在射出模真空系統中的應用不可忽視。它們能夠提供所需的真空度和穩定性,降低成本,提高生產效率。未來,隨著技術的進步,這些設備也將朝著更高效、更節能和更智能化的方向發展。售後服務的重要性也在不斷提升,以滿足客戶的需求。

關鍵字: Mechanical assisted pump, Vacuum pump, Vacuum system for injection mold

Title: Application of Mechanical Assisted Pump and Vacuum Pump in Vacuum System for Injection Mold

Article:

The vacuum system for injection mold plays a vital role in the plastic mold injection process. The mechanical assisted pump and vacuum pump, as the core components of the vacuum system, are crucial. This article will introduce the principles of the mechanical assisted pump and vacuum pump, as well as their applications in the vacuum system for injection mold. The future development trends will also be discussed.

A mechanical assisted pump is a device that uses mechanical force to enhance fluid pressure. In the vacuum system for injection mold, a mechanical assisted pump provides higher vacuum level and more stable operation, ensuring the proper filling of plastic material in the mold. Additionally, it helps reduce costs and improve production efficiency. The future development trend of the mechanical assisted pump focuses on energy efficiency and plays a greater role in automated production.

A vacuum pump is a device used to remove gas by creating a vacuum. In the vacuum system for injection mold, a vacuum pump creates a vacuum environment by extracting air and other impurities from the mold, promoting the flow and molding of plastic material. The choice and use of vacuum pumps directly affect the quality and production efficiency of injection molds. In the future, vacuum pumps will develop towards higher efficiency, stability, and intelligence to meet the increasing demands for product quality and efficiency.

With the development of the manufacturing industry, the demand for vacuum systems for injection mold is continuously increasing. After-sales service becomes essential to meet market demands. After-sales service includes maintenance, servicing, and technical support for mechanical assisted pumps and vacuum pumps. Providing high-quality after-sales service helps customers better utilize and maintain the equipment, prolonging their lifespan and improving production efficiency.

In conclusion, the application of mechanical assisted pumps and vacuum pumps in the vacuum system for injection mold cannot be ignored. They provide the required vacuum level and stability, reducing costs and improving production efficiency. In the future, with technological advancements, these devices will develop towards higher efficiency, energy savings, and intelligence. The importance of after-sales service is also increasing to meet customer needs.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)