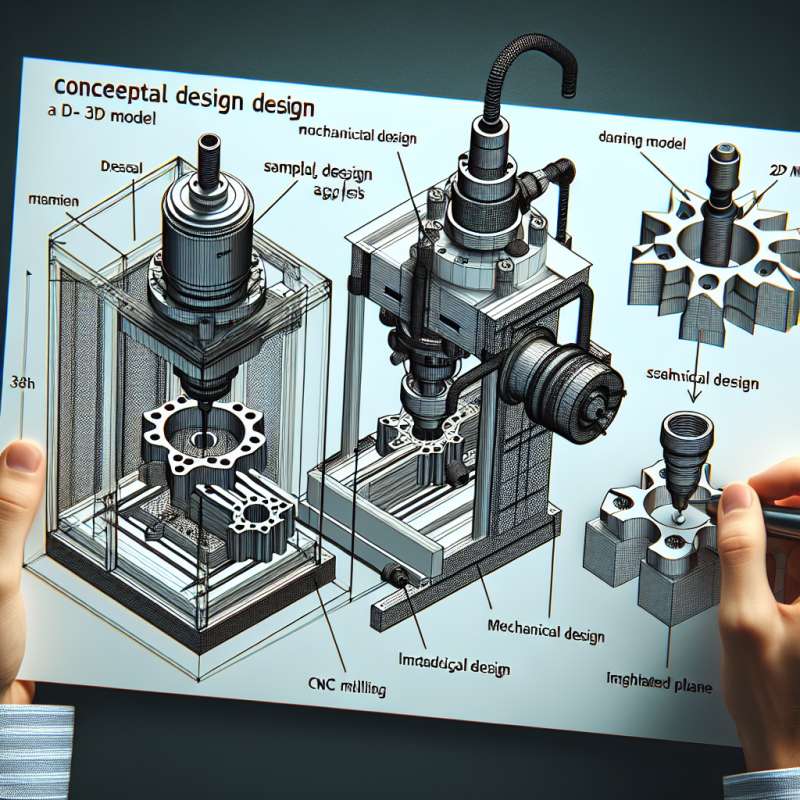

近年來,隨著科技的不斷進步,CNC技術在產業用機械設備領域中扮演著越來越重要的角色。CNC(Computer Numerical Control)是利用電腦控制數字指令來操作機械器具,使得生產過程更精確、效率更高。

在製造過程中,機械加工通常會伴隨著金屬切削過程中產生的油霧。為了保持工作環境的衛生和安全,油霧回收機成為了必不可少的設備。通過有效收集和處理油霧,不僅能降低環境污染,也能延長機器設備的使用壽命。

此外,隨著製造業的發展,產業用機械設備的安裝與維修服務需求也逐漸增長。冠通、誠泰、中義等公司為機械器具批發商,提供了專業的維修及安裝服務,確保客戶機器的正常運轉和性能。

在機械器具的表面處理方面,DLC(Diamond-Like Carbon)鍍層技術以及TiALN、TIN、TICN等黑鋁鈦材質的應用也日益普及。這些表面處理技術不僅能提升機械器具的硬度和耐磨性,還能延長其使用壽命,更適用於類鑽、車床、模具等產業用機械設備上。

總之,隨著產業用機械設備市場的需求增長,相關產品和服務的市場也將繁榮發展。這為機械器具批發、產業用機械設備維修及安裝、電腦及電腦週邊設備批發等行業帶來了新的商機和挑戰。

Keywords: CNC, DLC, Oil Mist Recovery System, Industrial Machinery Equipment Maintenance and Installation

Title: Growth in Market Demand for Industrial Machinery Equipment Driven by CNC Technology and Oil Mist Recovery Systems

Article: In recent years, with the advancement of technology, CNC technology has been playing an increasingly important role in the field of industrial machinery equipment. CNC (Computer Numerical Control) uses computer-controlled numerical instructions to operate machinery, making the production process more precise and efficient.

During the manufacturing process, metal cutting typically generates oil mist. To maintain a hygienic and safe work environment, oil mist recovery systems have become essential equipment. By effectively collecting and treating oil mist, not only can environmental pollution be reduced, but the lifespan of machinery equipment can also be extended.

Furthermore, with the development of the manufacturing industry, there is a growing demand for installation and maintenance services for industrial machinery equipment. Companies like Guan Tong, Cheng Tai, and Zhong Yi, who are wholesalers of machinery equipment, provide professional maintenance and installation services to ensure the normal operation and performance of clients' machines.

In terms of surface treatment of machinery equipment, DLC (Diamond-Like Carbon) coating technology and the application of TiALN, TIN, TICN, and other black aluminum titanium materials are also becoming increasingly popular. These surface treatment technologies not only improve the hardness and wear resistance of machinery equipment but also extend its lifespan, making them more suitable for industries such as drills, lathes, molds, etc.

In conclusion, with the growing demand in the market for industrial machinery equipment, related products and services will also prosper and develop. This brings new opportunities and challenges for industries such as wholesaling of machinery equipment, maintenance and installation of industrial machinery equipment, and wholesaling of computer and computer peripheral equipment.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)