塑膠製品在現代社會中扮演著重要的角色,它們廣泛應用於各個領域,從家庭用品到汽車部件,從電子設備到工業機械。如今,塑膠製品的需求不斷增長,同時也帶來了對設計、製造和相關行業的新需求和挑戰。

設計是塑膠製品製造過程中不可或缺的一環。隨著科技的發展,設計師現在能夠使用先進的軟體和工具來創造出更複雜、更具功能性的塑膠產品。透過應用設計技術,可以改善產品的外觀、性能和使用體驗,並提高產品在市場上的競爭力。

電子連接器(線)製造是塑膠產品製造中的一個重要領域。隨著科技的發展,電子設備越來越普及,對電子連接器的需求也越來越大。現代的電子連接器不僅需要小巧輕便,還需要具備高速傳輸、防水防塵等功能,這對塑膠製造業提出了更高的要求。

塑膠成型模具製造是塑膠產品製造中的關鍵一環。模具的設計和製造對產品的品質和生產效率有著重大影響。隨著技術的不斷進步,現代的模具可以更精確地複製產品的形狀和細節,並實現更高效的生產。研發更先進的塑膠成型模具技術將成為未來塑膠製造業發展的關鍵。

未分類其他塑膠製品製造是一個廣泛的領域,包含著各種不同類型的塑膠產品,從嬰兒用品到工業機械配件,從家居裝飾到食品包裝等等。這一領域的發展趨勢在於提高產品的品質和功能性,同時減少對環境的影響。可持續發展將成為塑膠製品製造業的未來發展方向之一。

總結而言,塑膠製品設計與製造的未來發展趨勢將朝著更先進、更高效、更環保的方向發展。隨著技術的進步和市場的需求變化,塑膠製品製造業將面臨著新的挑戰和機遇。只有不斷創新和提升專業能力,才能在激烈的市場競爭中取得成功。

關鍵字: Plastic, Design, Electronic Connector Manufacturing, Unclassified Plastic Product Manufacturing, Plastic Molding Mold Manufacturing

Title: Future Trends in Design and Manufacturing of Plastic Products

Article:

Plastic products play a crucial role in modern society, with a wide range of applications in various industries, from household items to automotive components, from electronic devices to industrial machinery. Today, the demand for plastic products is constantly growing, bringing new requirements and challenges to the design, manufacturing, and related industries.

Design is an essential part of the plastic product manufacturing process. With the advancement of technology, designers can now use advanced software and tools to create more complex and functional plastic products. By applying design techniques, product appearance, performance, and user experience can be improved, enhancing the competitiveness of the products in the market.

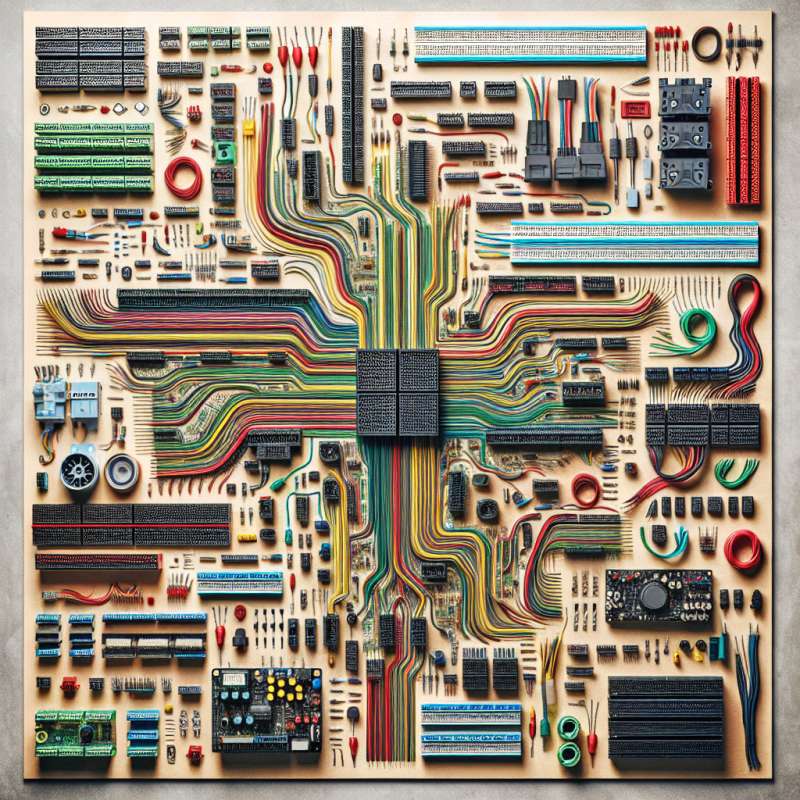

Electronic connector manufacturing is a significant area in the production of plastic products. With the development of technology, electronic devices are becoming more prevalent, leading to an increasing demand for electronic connectors. Modern electronic connectors not only need to be compact and lightweight but also require high-speed transmission and features such as water and dust resistance. This places higher demands on the plastic manufacturing industry.

Plastic molding mold manufacturing is a critical aspect of plastic product manufacturing. Mold design and manufacturing have a significant impact on product quality and production efficiency. With the continuous advancement of technology, modern molds can replicate product shapes and details more precisely, enabling more efficient production. Developing more advanced plastic molding mold technologies will be a key aspect of future developments in the plastic manufacturing industry.

Unclassified plastic product manufacturing encompasses a wide range of products, ranging from baby items to industrial machinery components, from home decor to food packaging, and more. The trend in this field is towards improving product quality and functionality while minimizing environmental impact. Sustainable development will become one of the future directions of the plastic product manufacturing industry.

In conclusion, the future trends in design and manufacturing of plastic products will focus on advanced, efficient, and eco-friendly approaches. With technological advancements and changing market demands, the plastic manufacturing industry will face new challenges and opportunities. Only through continuous innovation and improvement of professional capabilities can success be achieved in the fierce market competition.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)