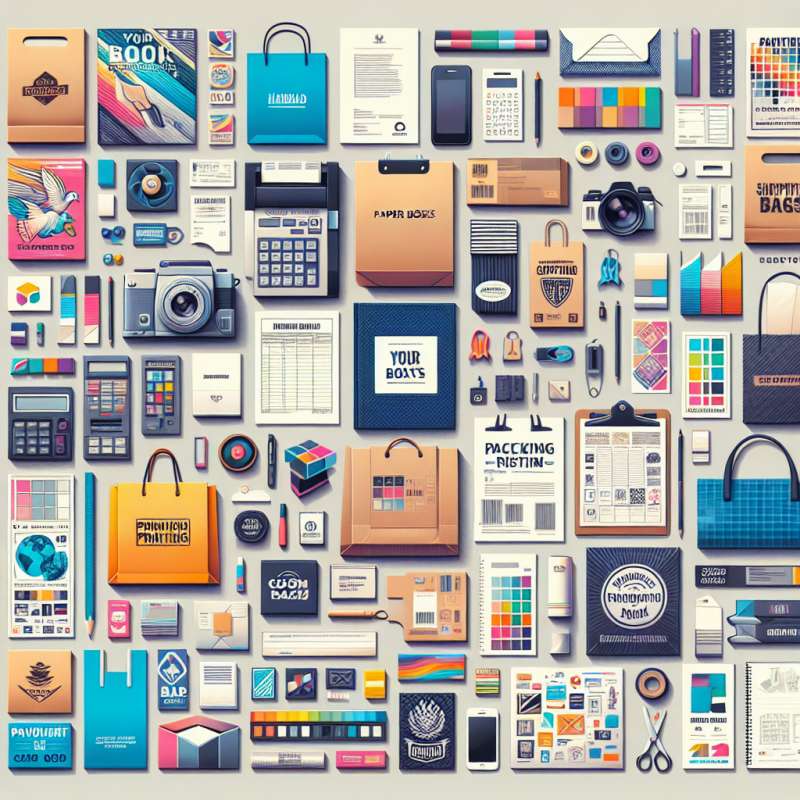

傳統的印刷業一直是許多公司推廣商品和品牌形象的重要方式之一。印刷品如說明書、產品目錄和彩盒等,能夠提供詳細的產品資訊和精美的品牌包裝,吸引消費者的注意力。而在印刷品製作的過程中,印刷品裝訂及加工是不可或缺的一環。

印刷品裝訂及加工是指將印刷過的紙張進行裝訂、整理和後續加工處理的過程。這項工藝既能保護印刷品的完整性,又能增加印刷品的實用性和觀賞性。隨著市場需求和科技的不斷發展,印刷品裝訂及加工領域也在進行著不斷的創新和改進。

首先,印刷品裝訂及加工的未來趨勢是與數位技術相結合。傳統的印刷品裝訂及加工通常是手工完成的,這樣的方式效率較低且容易出錯。而隨著數位技術的普及和進步,可以應用自動化和智能化設備來提高裝訂和加工效率。例如,可以使用數字化刀模裝訂機器,通過電腦控制裝訂刀模的位置和壓力,實現快速、準確的裝訂。

其次,印刷品裝訂及加工的未來趨勢是個性化和定制化製作。傳統的裝訂和加工方式通常是大規模的批量生產,無法滿足個別客戶的需求。而隨著消費者對個性化和定制化商品的需求增加,印刷品裝訂及加工業也開始朝著這個方向發展。例如,可以使用數字印刷技術,根據客戶的需求快速印刷和裝訂符合其要求的產品。

最後,印刷品裝訂及加工的未來趨勢是綠色環保。傳統的印刷和裝訂過程中,常常使用大量的紙張和化學藥劑,對環境造成一定的壓力。而綠色環保已經成為社會的共識和發展趨勢,印刷品裝訂及加工業也需要跟上這個潮流。例如,可以選擇使用環保紙張和綠色裝訂材料,減少對環境的影響。

總之,印刷品裝訂及加工的未來發展趨勢是與數位技術結合、個性化和定制化製作以及綠色環保相結合。隨著科技和市場的不斷進步,相信印刷品裝訂及加工業將朝著更高效、個性化和環保的方向發展。

關鍵字:Printing, Instruction manual, Product catalog, Color box, Changhua, Printing binding and processing

標題:The Future Trends of Printing Binding and Processing

The traditional printing industry has always been an important way for many companies to promote products and brand image. Printed materials such as instruction manuals, product catalogs, and color boxes provide detailed product information and beautifully designed brand packaging, attracting the attention of consumers. In the process of producing printed materials, printing binding and processing are indispensable.

Printing binding and processing refer to the process of binding, organizing, and further processing printed paper. This process not only protects the integrity of the printed materials but also improves their practicality and aesthetics. With the continuous development of market demand and technology, the field of printing binding and processing is constantly innovating and improving.

Firstly, the future trend of printing binding and processing is integrating with digital technology. Traditional printing binding and processing are usually done manually, which is inefficient and prone to errors. With the popularization and advancement of digital technology, automation and intelligent equipment can be used to improve binding and processing efficiency. For example, digital die-cutting machines can be used, and the position and pressure of the die-cutting can be controlled by computers to achieve fast and accurate binding.

Secondly, the future trend of printing binding and processing is personalized and customized production. Traditional binding and processing methods are usually mass-produced and cannot meet the individual needs of customers. With the increasing demand for personalized and customized products, the printing binding and processing industry is also moving in this direction. For example, digital printing technology can be used to quickly print and bind products that meet customers' requirements.

Lastly, the future trend of printing binding and processing is green and environmentally friendly. The traditional printing and binding processes often use a large amount of paper and chemical agents, which puts pressure on the environment. Environmental protection has become a consensus and development trend in society, and the printing binding and processing industry needs to keep up with this trend. For example, choosing environmentally friendly paper and green binding materials can reduce the impact on the environment.

In conclusion, the future trends of printing binding and processing are integrating with digital technology, personalized and customized production, and green and environmentally friendly practices. With the continuous progress of technology and the market, it is believed that the printing binding and processing industry will develop towards more efficient, personalized, and environmentally friendly directions.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)