近年來,電著產業全球發展迅速,為了因應市場競爭壓力與提升效能,許多企業紛紛尋求自動化規劃與前處理設備的協助。這些設備不僅能夠提高製造流程的效率,還能確保產品品質的一致性,並減少人為失誤。

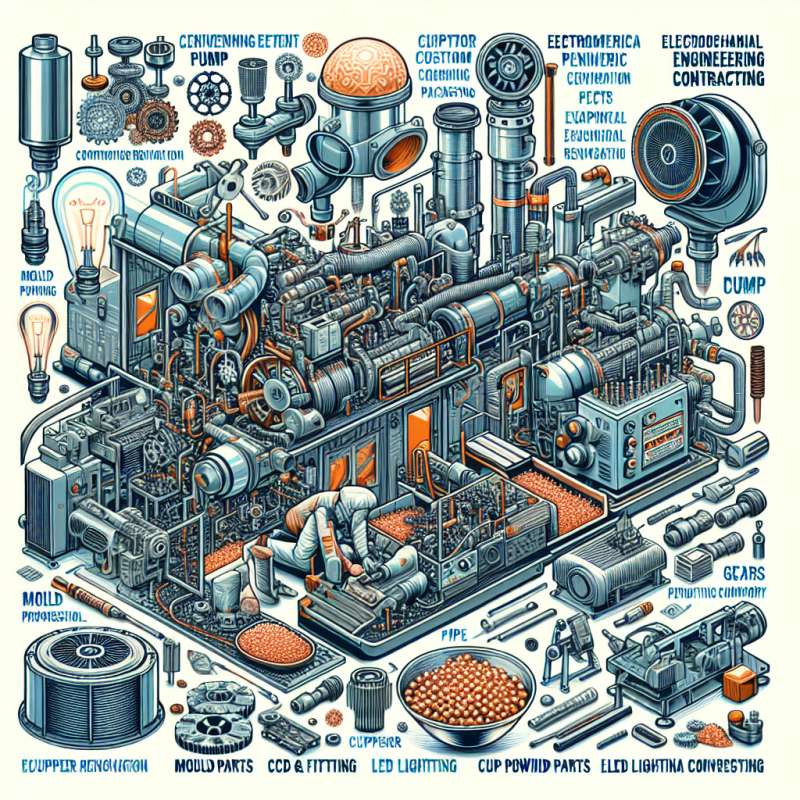

自動化規劃是未來發展的趨勢之一。透過自動化系統,企業能夠實現生產線的製程連續化,從而大幅提升生產效率。自動化規劃不僅包括自動物流儲運系統的組立和生產輸送設備的操作,還包括整廠自動化的設計與布局。這些自動化系統的應用,可以大大減少人為操作的瑕疵,同時降低生產成本。

另一個重要趨勢是前處理設備的應用。前處理設備在電著產業中扮演著重要的角色,它能夠對產品進行清潔、除銹、除油等處理,確保良好的附著性和表面質量。隨著市場對於品質和效能的要求越來越高,前處理設備的自動化和智能化亦將越來越重要。例如,透過機器視覺和感應技術,可以實現對產品表面的自動檢測和處理,大大提高生產效率和品質控制。

生產輸送設備也是未來發展的一個關鍵領域。這些設備在電著產業中扮演著搬運、組裝和生產的重要角色,它們不僅需要擁有高度的自動化和智能化功能,還需要具備高效能、節能減排的特點。此外,隨著乾燥爐等設備的發展和應用,對於乾燥爐各式洗淨和安全防護的需求也越來越高。

面對未來電著產業的發展趨勢,企業應該加強對自動化規劃和前處理設備的研發和應用。同時,也應該關注生產輸送設備的改進和升級,以符合市場的需求和環保的要求。只有不斷創新和引進新技術,企業才能夠在競爭激烈的電著產業中保持競爭力。

Title: Future Development Trends of Automation Planning and Pre-treatment Equipment in the Electrocoating Industry

Article:

The electrocoating industry has been rapidly developing globally in recent years. In order to cope with market competition and improve efficiency, many companies are seeking the assistance of automation planning and pre-treatment equipment. These equipment not only improve the efficiency of manufacturing processes but also ensure consistent product quality and reduce human errors.

Automation planning is one of the future development trends. Through automated systems, companies can achieve continuous process flow and significantly enhance production efficiency. Automation planning includes not only the assembly of automated logistics and transportation systems but also the design and layout of fully automated plants. The application of these automation systems can greatly reduce human errors and lower production costs.

Another important trend is the application of pre-treatment equipment. Pre-treatment equipment plays a crucial role in the electrocoating industry as it can clean, derust, degrease, and treat products to ensure good adhesion and surface quality. With increasing market demands for quality and performance, automation and intelligence of pre-treatment equipment will become essential. For example, through machine vision and sensing technologies, automatic detection and treatment of product surfaces can be achieved, greatly improving production efficiency and quality control.

Production transportation equipment is also a key area for future development. These equipment play important roles in handling, assembly, and production in the electrocoating industry. They need to possess high automation and intelligence functions as well as high efficiency and energy-saving features. Additionally, with the development and application of drying furnaces, there is an increasing demand for various cleaning and safety protection measures.

In the face of future development trends in the electrocoating industry, companies should strengthen research, development, and application of automation planning and pre-treatment equipment. They should also focus on improving and upgrading production transportation equipment to meet market demands and environmental requirements. Only through continuous innovation and the adoption of new technologies can companies maintain competitiveness in the competitive electrocoating industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)