近年來,橡膠製品製造產業的發展日漸受到矚目。隨著科技進步及市場需求的不斷提升,製造商紛紛投入研究與開發,以應對趨勢性的需求。

AirHose 是一種耐酸、耐鹼的橡膠製品,廣泛應用於空氣管和進氣管等領域。擁有優異的性能,可有效防塵,耐油且耐氣候,適合各種惡劣環境下的使用。由於 AirHose 的特性,使其在工業和汽車製造領域受到廣泛應用。

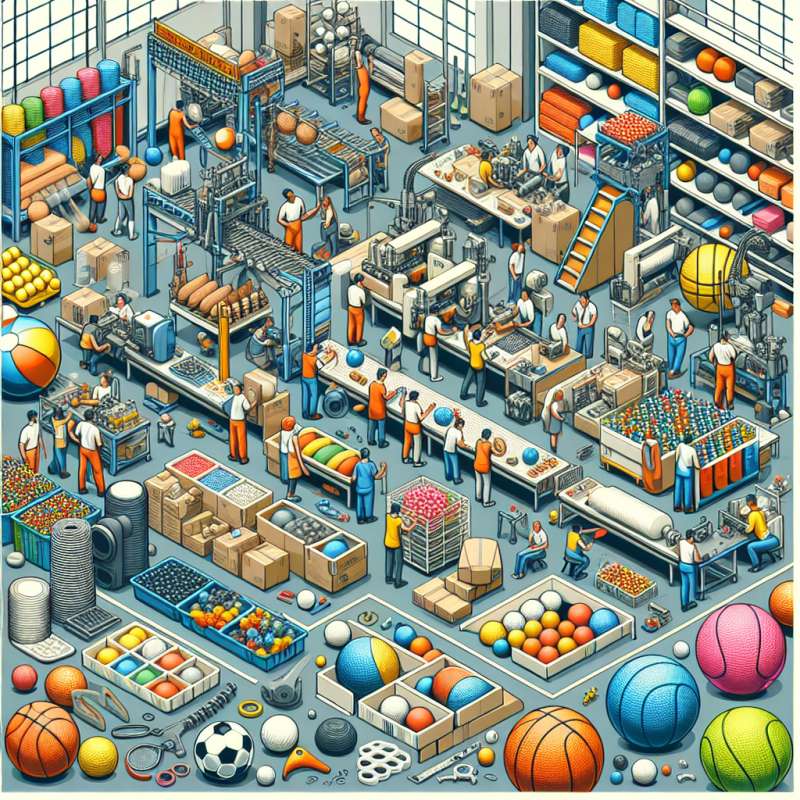

射出成型技術則是現代橡膠製品製造的重要工藝之一。透過射出成型,製造商可以快速生產出各種形狀和尺寸的橡膠製品,並確保產品的質量和一致性。這種高效率的製造方法,不僅節省生產成本,同時也提高了生產效率和產品的競爭力。

在未來,橡膠製品製造業將持續朝著更環保、更高效、更高品質的方向發展。橡膠製品製造商應該不斷創新,尋找新的材料與技術,以滿足不斷變化的市場需求。因此,橡膠製品製造業勢必在全球市場中佔據更重要的地位。

Keywords: rubber product manufacturing, AirHose, injection molding

Title: Exploring the Trends in Rubber Product Manufacturing

Article: In recent years, the development of the rubber product manufacturing industry has been increasingly attracting attention. With the advancement of technology and the continuous improvement of market demand, manufacturers have been investing in research and development to meet the trend-driven demands.

AirHose is a rubber product that is resistant to acid and alkali, widely used in areas such as air hoses and intake pipes. With excellent performance, it can effectively prevent dust, resist oil and climates, suitable for use in various harsh environments. Due to the characteristics of AirHose, it is widely used in the industrial and automotive manufacturing sectors.

Injection molding technology is one of the key processes in modern rubber product manufacturing. Through injection molding, manufacturers can quickly produce rubber products of various shapes and sizes, ensuring product quality and consistency. This highly efficient manufacturing method not only saves production costs but also increases production efficiency and product competitiveness.

In the future, the rubber product manufacturing industry will continue to develop towards more environmentally friendly, efficient, and higher quality directions. Manufacturers of rubber products should continue to innovate, search for new materials and technologies to meet the constantly changing market demands. Therefore, the rubber product manufacturing industry is bound to occupy a more important position in the global market.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)