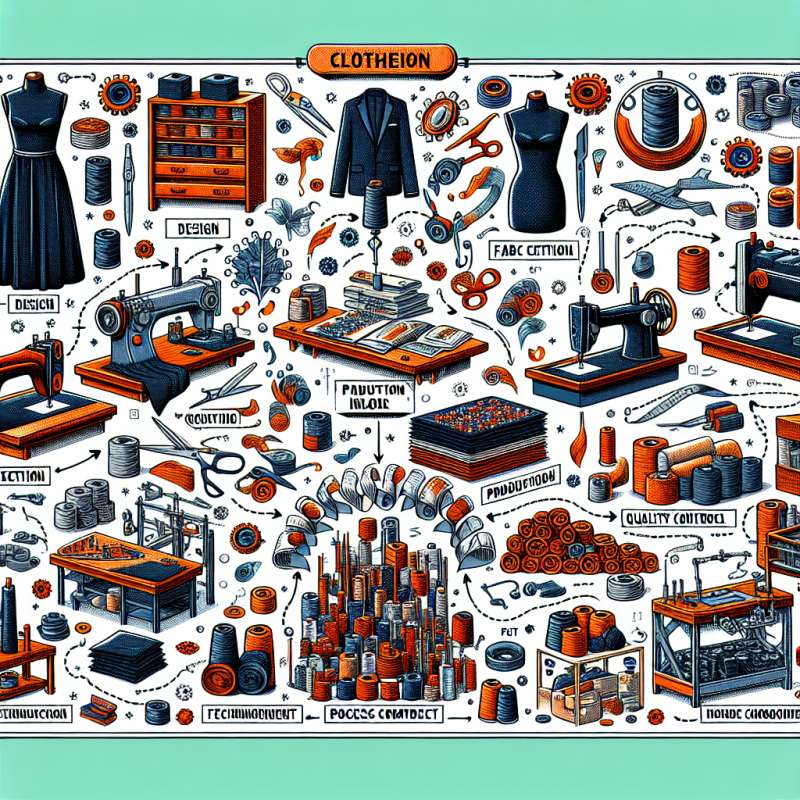

在製造業中,設計與裁剪是其中非常重要的兩個步驟。設計階段決定了產品的外觀和功能,而裁剪則是確保布料能夠有效利用並縫製出符合設計要求的成品。在這個工藝過程中,品質控制也是至關重要的一環,確保產品符合客戶的需求和標準。

製造流程中的設計階段通常由設計師負責,他們會根據市場需求和趨勢來設計新款式或改良現有產品。而裁剪則是將設計圖紙上的設計轉換為實際的布料零件。透過精確的裁剪,可以節省布料的浪費並提高生產效率。

生產技術在製造過程中也扮演了重要角色,依靠先進的設備和技術,可以提高生產效率並保證產品的品質。流程管理則是確保製造過程中的每一個步驟都能夠順利進行,做到無廢料和高效率。

總的來說,製造過程中的設計和裁剪是非常重要的環節,需要精準的技術和品質控制來保證產品的品質。這些步驟必須緊密配合,才能製造出令客戶滿意的產品。

Keywords: Manufacturing, Design, Cutting

Title: Design and Cutting Techniques in the Manufacturing Process

Article: In the manufacturing industry, design and cutting are two crucial steps in the process. The design phase determines the appearance and functionality of the product, while cutting ensures that the fabric is efficiently utilized to sew the final product that meets the design requirements. Quality control is also an essential part of this process, ensuring that the products meet customer needs and standards.

The design phase of the manufacturing process is typically led by designers, who create new styles or improve existing products based on market demands and trends. Cutting, on the other hand, transforms the design on paper into actual fabric parts. Precise cutting saves fabric wastage and increases production efficiency.

Production technology plays a significant role in the manufacturing process, utilizing advanced equipment and techniques to improve efficiency and ensure product quality. Process management ensures that every step of the manufacturing process runs smoothly, achieving zero waste and high efficiency.

In conclusion, design and cutting are crucial aspects of the manufacturing process, requiring precise techniques and quality control to ensure product quality. These steps must work closely together to manufacture products that satisfy customers.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)