隨著科技的不斷進步和人們對環境保護的重視,新產品的研究開發已成為各個領域中重要的趨勢之一。在汽車行業中,冷氣系統是不可或缺的一部分,而不織布材料的使用在該領域中具有巨大的潛力。

不織布是一種以化學纖維為主要材料並經過特殊加工製成的材料,它具有輕便、耐用、透氣性好等特點。這些特性使得不織布材料在汽車冷氣系統中的應用非常有前景。

首先,不織布材料可以用於汽車冷氣濾芯的製造。它可以有效地過濾空氣中的灰塵、花粉和細菌等有害物質,提供乘客們一個清新的車內環境。同時,不織布材料還具有較長的使用壽命,減少了更換濾芯的頻率和成本。

其次,不織布材料還可以用於汽車冷氣系統的隔離層製造。隔離層可以有效地阻擋外界的熱量進入車內,提供乘客們一個舒適的車內環境。同時,不織布材料還具有良好的隔音效果,減少車內噪音對乘客的干擾。

未來,在汽車冷氣領域中,研發新材料和新技術的趨勢將更加明顯。不織布材料作為一種新興材料,將會在汽車冷氣系統中發揮更多的作用。同時,研究開發高效能的PE材料和有機化學材料也是未來的重點。這些材料能夠提供更好的性能和更長的使用壽命,進一步提升汽車冷氣系統的效能。

總結而言,新產品的研究開發在汽車冷氣領域中取得了顯著的進展。不織布材料的應用為汽車冷氣系統提供了更好的過濾效果和隔熱效果。未來,隨著科技的不斷發展和需求的增加,研究開發新材料和新技術將成為汽車冷氣領域的主要趨勢。

關鍵字: PE, 材料, 化學, 平面, 污染防治設備製造

標題: 化學材料在平面污染防治設備製造中的應用

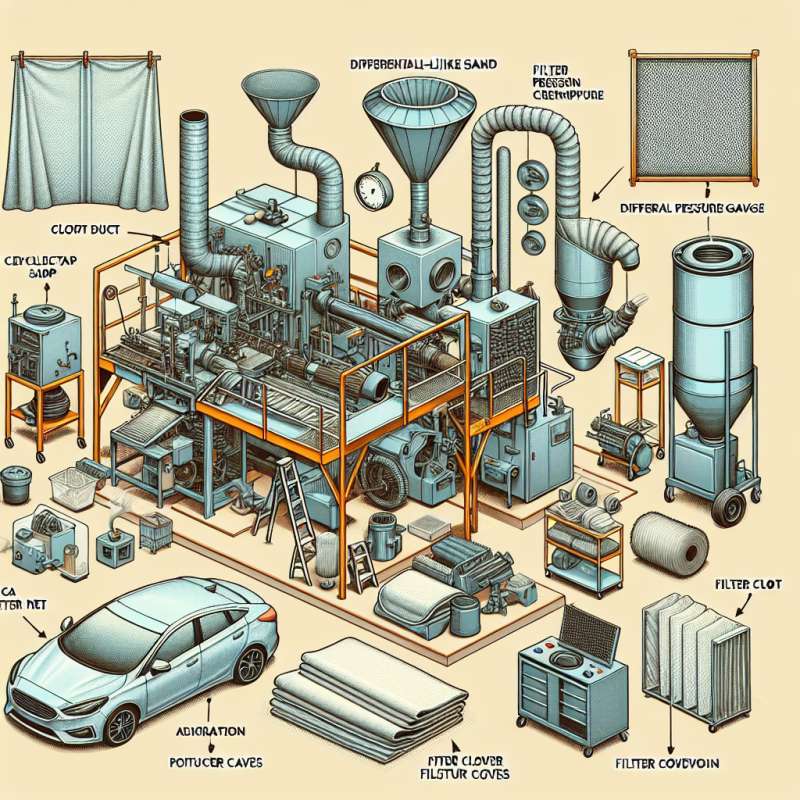

在現今社會,環境污染已成為一個全球性的問題,因此污染防治設備的研發和製造變得至關重要。化學材料是平面污染防治設備製造中一個不可或缺的元素。

PE材料是一種常見且廣泛應用的材料之一,它具有耐腐蝕、耐高溫和抗壓性能優越的特點。這些特性使得PE材料成為平面污染防治設備製造中的理想選擇。舉例而言,PE材料可以用於製造污染防治設備的管路和容器。其耐腐蝕性和耐高溫性能使得這些設備能夠有效地抵抗各種腐蝕性氣體和液體的侵蝕,保證設備的長期運行。

此外,化學材料也可以應用於平面污染防治設備的過濾媒體制造上。過濾媒體是污染防治設備中的關鍵組件,能夠有效地去除空氣和水中的污染物。化學材料的特性使得它們能夠擁有更大的表面積和更好的吸附性能,提高過濾效率和使用壽命。

展望未來,化學材料在平面污染防治設備製造中的應用將會持續增加。隨著環境問題的嚴重性和法規的不斷加強,對於高效能和環保型污染防治設備的需求也將大幅增長。因此,研究開發更多性能優越的化學材料將成為未來的重點。這些材料將擁有更高的耐化學和耐溫性能,能夠應對更嚴苛的工藝條件,提供更可靠的污染防治解決方案。

總而言之,化學材料在平面污染防治設備製造中的應用具有重要意義。PE材料的耐腐蝕和抗壓性能使其成為製造平面污染防治設備的理想材料。未來,隨著環境意識的提高和法規的加強,研究開發更多性能優越的化學材料將成為平面污染防治設備製造的未來發展趨勢。

Translation:

Keywords: new product, non-woven fabric, research and development, automotive, air conditioning

Title: Application of R&D on New Products in the Automotive Air Conditioning Sector

Article:

With the continuous advancement of technology and increasing emphasis on environmental protection, the research and development of new products has become a significant trend in various industries. In the automotive sector, air conditioning systems are an essential part, and the use of non-woven fabric materials has promising potential in this field.

Non-woven fabric is a material made from chemical fibers through special processing, known for its lightweight, durability, and good breathability. These characteristics make non-woven fabric materials highly suitable for applications in automotive air conditioning systems.

Firstly, non-woven fabric materials can be used in the manufacturing of filters for automotive air conditioning. They effectively filter out harmful substances such as dust, pollen, and bacteria, providing passengers with a fresh interior environment. Additionally, non-woven fabric materials have a longer lifespan, reducing the need for frequent filter replacements and associated costs.

Secondly, non-woven fabric materials can also be used in the production of insulation layers for automotive air conditioning systems. These layers effectively block external heat from entering the vehicle, creating a comfortable interior environment for passengers. Additionally, non-woven fabric materials offer good sound insulation properties, reducing noise interference inside the vehicle.

In the future, the development of new materials and technologies will be prominent in the automotive air conditioning sector. As an emerging material, non-woven fabric will play an even more significant role in automotive air conditioning systems. Alongside, research and development of high-performance PE materials and organic chemicals will be a key focus. These materials can provide better performance and longer lifespan, further enhancing the efficiency of automotive air conditioning systems.

In conclusion, the research and development of new products have made significant progress in the automotive air conditioning field. The application of non-woven fabric materials improves the filtration efficiency and heat insulation of automotive air conditioning systems. Looking ahead, with continuous technological advancements and increasing demand, the research and development of new materials and technologies will be the main trend in the automotive air conditioning sector.

Keywords: PE, materials, chemistry, flat, pollution control equipment manufacturing

Title: Application of Chemical Materials in Flat Pollution Control Equipment Manufacturing

Article:

In today's society, environmental pollution has become a global issue, making the development and manufacturing of pollution control equipment crucial. Chemical materials are an essential element in the manufacturing of flat pollution control equipment.

PE material is one of the commonly used and widely applied materials, known for its excellent corrosion resistance, high-temperature resistance, and compression performance. These characteristics make PE material an ideal choice for manufacturing flat pollution control equipment. For example, PE materials can be used in the production of pipelines and containers for pollution control equipment. Their corrosion resistance and resistance to high temperatures enable these devices to effectively resist various corrosive gases and liquids, ensuring prolonged equipment operation.

Additionally, chemical materials can also be applied in the manufacturing of filter media for flat pollution control equipment. Filter media are crucial components in pollution control equipment, capable of effectively removing pollutants from air and water. The characteristics of chemical materials, such as larger surface area and better adsorption performance, improve filtration efficiency and lifespan.

Looking ahead, the application of chemical materials in flat pollution control equipment manufacturing will continue to grow. With the severity of environmental issues and increasingly stringent regulations, the demand for high-performance and environmentally-friendly pollution control equipment will significantly increase. Therefore, researching and developing more superior chemical materials will be a key focus. These materials will possess higher chemical resistance and temperature resistance, allowing them to withstand harsher process conditions and provide reliable pollution control solutions.

In conclusion, the application of chemical materials in flat pollution control equipment manufacturing is of great significance. The superior corrosion resistance and compression performance of PE materials make them the ideal choice for manufacturing flat pollution control equipment. Looking to the future, with increased environmental awareness and stricter regulations, the research and development of superior chemical materials will be the future development trend in flat pollution control equipment manufacturing.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)