晶圓清洗機和Metaliftoff是電子製造過程中關鍵的機械設備,它們在生產晶圓和去光阻的過程中扮演著重要的角色。隨著科技的發展和需求的增加,晶圓清洗機和Metaliftoff正在進行升級和改進,以滿足更高的生產要求。

晶圓清洗機是一種用於清洗製造出的晶圓表面的設備。它的主要功能是去除晶圓表面的污染物和殘留物,以確保晶圓的純度和品質。隨著晶圓製造技術的進步,晶圓的表面越來越複雜,需要更高精度的清洗機來應對。未來,晶圓清洗機將採用更先進的清洗技術,如超聲波清洗和氣體清洗,以實現更高效率和更佳的清洗效果。

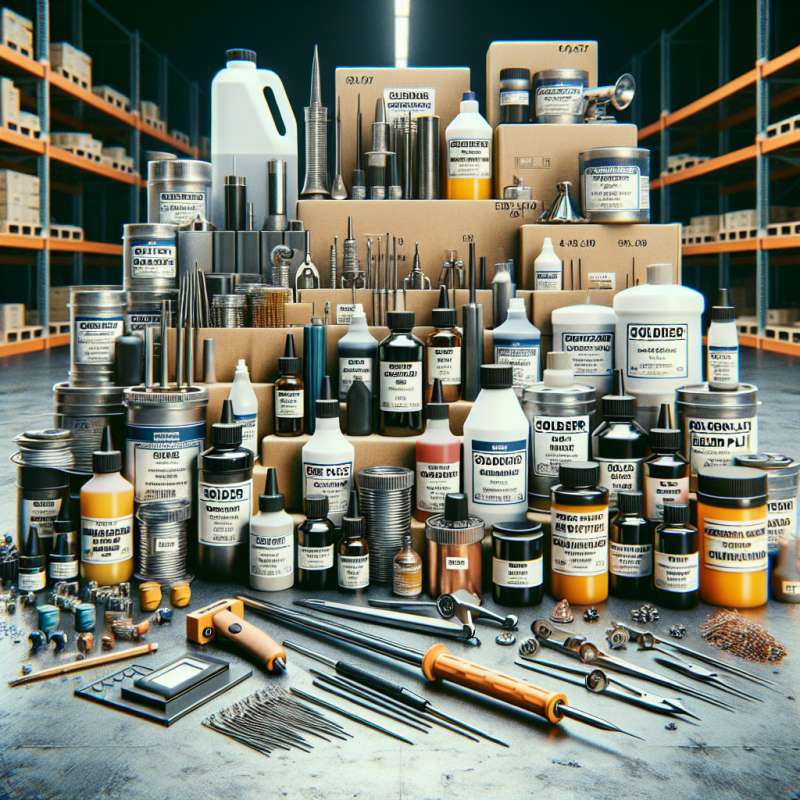

Metaliftoff則是一種用於去除光阻層的溶劑。光阻是一種用於製造電子元件的薄膜材料,它在製程完成後需要被去除。Metaliftoff的主要作用是將光阻溶解,使其易於去除。隨著製造技術的進步和要求的提高,Metaliftoff也需要不斷改進和升級。未來,Metaliftoff將繼續提高其去除光阻的效率和質量,並考慮可再利用性和環保性。

在機械設備維修和安裝行業中,通用機械設備維修和安裝是一個重要的領域。隨著各行業的發展,許多機械設備需要進行維修和安裝,以確保其正常運行和機械效能。然而,這也帶來了一些挑戰。首先,這些設備的技術和操作要求不斷變化,需要持續學習和更新知識。其次,市場競爭加劇,設備維修和安裝的價格壓力也增加。因此,機械設備維修和安裝業面臨著提高技術水平、提升服務品質和降低成本的挑戰。

未來,晶圓清洗機和Metaliftoff將繼續在電子製造行業中扮演重要的角色。隨著技術的不斷進步,它們將不斷升級和改進,以滿足越來越高的生產需求。同時,機械設備維修和安裝行業也將面臨著挑戰,需要不斷提升技術水平和服務品質,以應對競爭壓力。

關鍵字: Wafer cleaning machine, Metaliftoff, General machinery equipment maintenance and installation

Title: Future Trends and Challenges in Wafer Cleaning Machine, Metaliftoff, and General Machinery Equipment Maintenance and Installation

Article:

Wafer cleaning machine and Metaliftoff are essential machinery equipment in the electronic manufacturing process, playing crucial roles in wafer production and photoresist removal. With the advancement of technology and increasing demand, wafer cleaning machine and Metaliftoff are being upgraded and improved to meet higher production requirements.

The wafer cleaning machine is a device used to clean the surface of manufactured wafers. Its main function is to remove contaminants and residues from the wafer surface to ensure purity and quality. As wafer manufacturing technology advances, the wafer's surface becomes more complex, requiring higher precision cleaning machines to cope. In the future, wafer cleaning machines will adopt more advanced cleaning techniques such as ultrasonic cleaning and gas cleaning to achieve higher efficiency and better cleaning results.

Metaliftoff, on the other hand, is a solvent used for removing the photoresist layer. Photoresist is a thin film material used in the production of electronic components which needs to be removed after processing. Metaliftoff's main role is to dissolve the photoresist, making it easier to remove. With the improvement of manufacturing technology and higher requirements, Metaliftoff also needs continuous improvement and upgrades. In the future, Metaliftoff will continue to enhance its efficiency and quality of photoresist removal while considering reusability and environmental-friendliness.

In the general machinery equipment maintenance and installation industry, general machinery equipment maintenance and installation are critical. With the development of various industries, many machinery equipment needs maintenance and installation to ensure their normal operation and mechanical efficiency. However, this also brings challenges. Firstly, the technical and operational requirements of these equipment are constantly changing, requiring continuous learning and knowledge updates. Secondly, market competition intensifies, putting pressure on the price of equipment maintenance and installation. Therefore, the machinery equipment maintenance and installation industry faces challenges in improving technical capabilities, enhancing service quality, and reducing costs.

In the future, wafer cleaning machines and Metaliftoff will continue to play crucial roles in the electronic manufacturing industry. With the continuous advancement of technology, they will be continuously upgraded and improved to meet the increasing production demands. At the same time, the general machinery equipment maintenance and installation industry will also face challenges, requiring continuous improvement in technical capabilities and service quality to cope with competitive pressures.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)