自動化技術在塑膠設計中的環境影響及未來發展趨勢

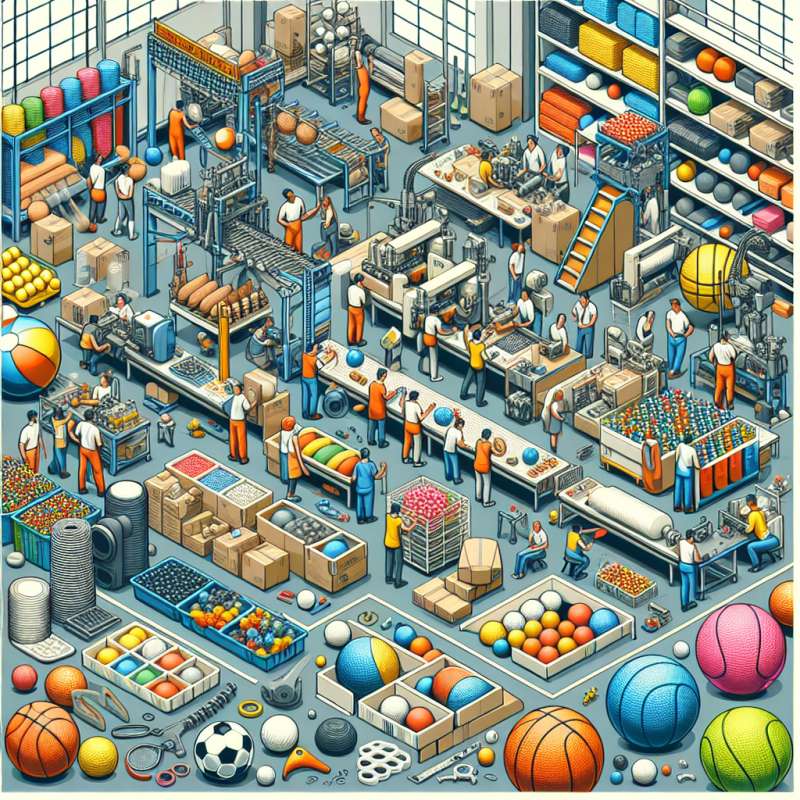

自動化技術的快速發展正在改變塑膠製造行業,並對環境產生重要影響。透過自動化的應用,塑膠設計和生產的效率得以提升,同時也減少了對環境的負面影響。下面將探討自動化技術在塑膠設計中所帶來的環境影響,以及未來發展趨勢。

首先,自動化技術的應用可以大大降低塑膠製品的生產成本。傳統上,塑膠製品的生產通常需要大量的人力和時間,造成了高昂的營運成本。但通過使用自動化設備,塑膠製品的生產可以實現無人化操作,從而降低了人力成本,提高了生產效率。

其次,自動化技術的應用還可以減少對環境的不良影響。傳統的塑膠製造過程通常需要大量能源和資源的消耗,並且會產生大量的廢物和污染物。然而,隨著自動化技術的應用,可以實現塑膠設計和生產的精確控制,減少了能源和資源的浪費,同時也減少了廢物的產生,減少了對環境的負擔。

未來,隨著自動化技術的不斷發展,塑膠設計將朝著更加智能化和環境友好的方向發展。AI人工智能技術的應用將提供更高效和精確的塑膠設計能力,同時還可以實現對設計過程的智能監控和優化,從而進一步提高生產效率和質量。

此外,隨著綠色環保意識的增強,塑膠設計和生產將更加注重環境友好性。在設計階段,將更加注重材料的可循環性和可降解性,以減少塑膠製品對環境的影響。同時,在生產過程中,將不斷尋求新技術和方法,以減少能源和資源的消耗,減少廢物的產生。

總結而言,自動化技術在塑膠設計中的應用正發揮著重要作用,同時也對環境產生了影響。未來,塑膠設計將朝著更加智能化和環境友好的方向發展,通過應用AI技術和注重環保,將實現更高效和環境友好的塑膠產品設計和生產。

關鍵字: Automation, Technical Services, Plastics, Environment, Design

Title: Environmental Impact and Future Development Trends of Automation Technology in Plastic Design

Article:

The rapid development of automation technology is changing the plastics manufacturing industry and has significant implications for the environment. Through the application of automation, the efficiency of plastic design and production is improved while also reducing its negative impact on the environment. This article will explore the environmental impact of automation technology in plastic design and discuss future development trends.

Firstly, the application of automation technology can significantly reduce the production costs of plastic products. Traditionally, the production of plastic products requires a considerable amount of manpower and time, resulting in high operating costs. However, through the use of automated equipment, the production of plastic products can be achieved through unmanned operations, thereby reducing labor costs and improving production efficiency.

Secondly, the application of automation technology can also minimize adverse environmental impacts. The traditional plastic manufacturing process often involves substantial energy and resource consumption and generates a significant amount of waste and pollutants. However, with the application of automation technology, precise control over plastic design and production can be achieved, reducing energy and resource waste and minimizing waste production, thereby reducing the environmental burden.

In the future, with the continuous development of automation technology, plastic design will evolve towards greater intelligence and environmental friendliness. The application of AI technology will provide more efficient and precise plastic design capabilities while also enabling intelligent monitoring and optimization of the design process, thereby further enhancing production efficiency and quality.

Moreover, with the growing emphasis on environmental conservation, plastic design and production will pay more attention to environmental friendliness. In the design stage, a greater focus will be placed on the recyclability and degradability of materials to reduce the environmental impact of plastic products. Meanwhile, in the production process, ongoing efforts will be made to seek new technologies and methods to reduce energy and resource consumption and minimize waste production.

In conclusion, the application of automation technology plays a crucial role in plastic design while also impacting the environment. In the future, plastic design will move towards greater intelligence and environmental friendliness, achieved through the application of AI technology and a focus on environmental sustainability, resulting in more efficient and environmentally friendly plastic product design and production.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)