現代科技迅速發展,對於矽晶圓製造行業帶來了許多新技術和設備的革新。濕式清洗機、bench、塗佈機、以及顯影清洗機等設備在矽晶圓製造中扮演著重要角色。

濕式清洗機是一種高效的清洗設備,能夠將矽晶圓表面的污垢和雜質徹底清潔,保證產品的純淨度和品質。bench則是用來對矽晶圓進行測試和測量的工作台,能夠提高工作效率和準確度。而塗佈機則用於在矽晶圓表面均勻塗布薄膜,以實現特定功能。顯影清洗機則可對矽晶圓上的圖案進行清洗和顯影處理,使得圖案清晰可見。

在矽晶圓製造中,這些設備不僅能提高生產效率和品質,同時也有助於降低生產成本和減少浪費。隨著技術的不斷進步和創新,矽晶圓製造行業將會迎來更多新的設備和技術的應用,進一步推動行業的發展。

Translation:

Keywords: Wet Cleaning Machine, Bench, Coater, Developer Cleaning Machine, Silicon Wafer Manufacturing

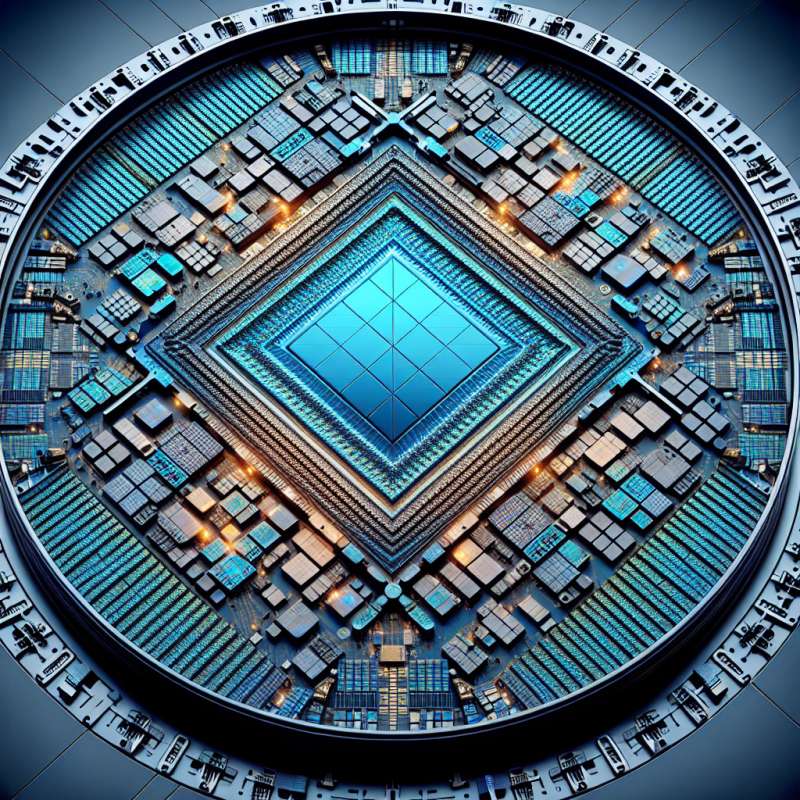

Title: Application of New Technology in Silicon Wafer Manufacturing

Article: With the rapid development of modern technology, the semiconductor industry has seen many innovations in terms of new technologies and equipment for silicon wafer manufacturing. Wet cleaning machines, benches, coaters, and developer cleaning machines play crucial roles in the manufacturing process.

Wet cleaning machines are efficient equipment used to thoroughly clean the surface of silicon wafers, ensuring purity and quality of the products. Benches are workstations used for testing and measuring wafers, increasing work efficiency and accuracy. Coaters are utilized to uniformly apply thin films on the surface of the wafers to achieve specific functions. Developer cleaning machines are used for cleaning and developing patterns on the wafers, making the patterns clearly visible.

In silicon wafer manufacturing, these equipment not only enhance production efficiency and quality but also help reduce production costs and waste. With continuous technological advancements and innovations, the semiconductor industry will witness the application of more new equipment and technologies, further driving the industry's development.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)