近年來,塑膠製品的需求不斷增加,這也帶動了塑膠化工機械設備製造行業的發展。其中,齒輪箱、成型機和押出機等設備在生產塑膠製品時扮演著重要角色。

齒輪箱是塑膠成型機械中的關鍵部件之一,它能夠將旋轉運動轉換為直線運動,帶動機器進行各種操作。隨著技術的不斷升級,齒輪箱的耐磨性和耐用性也在不斷提高,能夠更有效地應對高強度的生產需求。

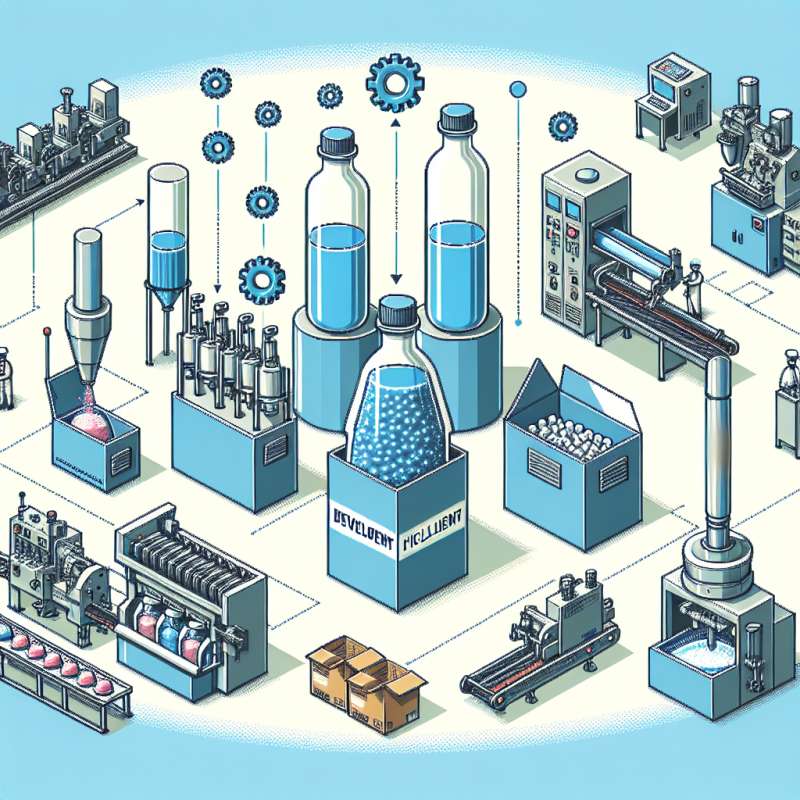

成型機和押出機則負責將加熱過的塑料原料塑造成各種形狀和尺寸的塑膠製品。隨著人們對環保產品的需求增加,塑膠製品的生產也更加講究節能減排,因此成型機和押出機的節能設計和高效率操作成為了設備製造商們的重要研發方向。

未來,隨著科技的發展和市場需求的變化,塑膠化工機械設備製造行業將會迎來更多機遇和挑戰。設備製造商需要不斷創新,提升產品的品質和性能,以滿足客戶日益增長的需求。

Keywords: Plastic, Gearbox, Molding machine, Extruder

Title: Future Development Trends of Plastic Chemical Machinery Manufacturing

Article: In recent years, the demand for plastic products has been increasing, driving the development of the plastic chemical machinery manufacturing industry. Among them, gearboxes, molding machines, and extruders play important roles in producing plastic products.

The gearbox is a key component in plastic molding machinery, converting rotational motion into linear motion to drive the machine for various operations. With continuous technological upgrades, the wear resistance and durability of gearboxes have been improved to effectively meet high-intensity production demands.

Molding machines and extruders are responsible for molding heated plastic raw materials into various shapes and sizes of plastic products. With the increasing demand for environmentally friendly products, the production of plastic products also emphasizes energy conservation and emission reduction. Therefore, energy-saving design and high-efficiency operation of molding machines and extruders have become important research and development directions for equipment manufacturers.

In the future, with the development of technology and changes in market demand, the plastic chemical machinery manufacturing industry will face more opportunities and challenges. Equipment manufacturers need to innovate continuously, improve the quality and performance of products to meet the growing demands of customers.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)