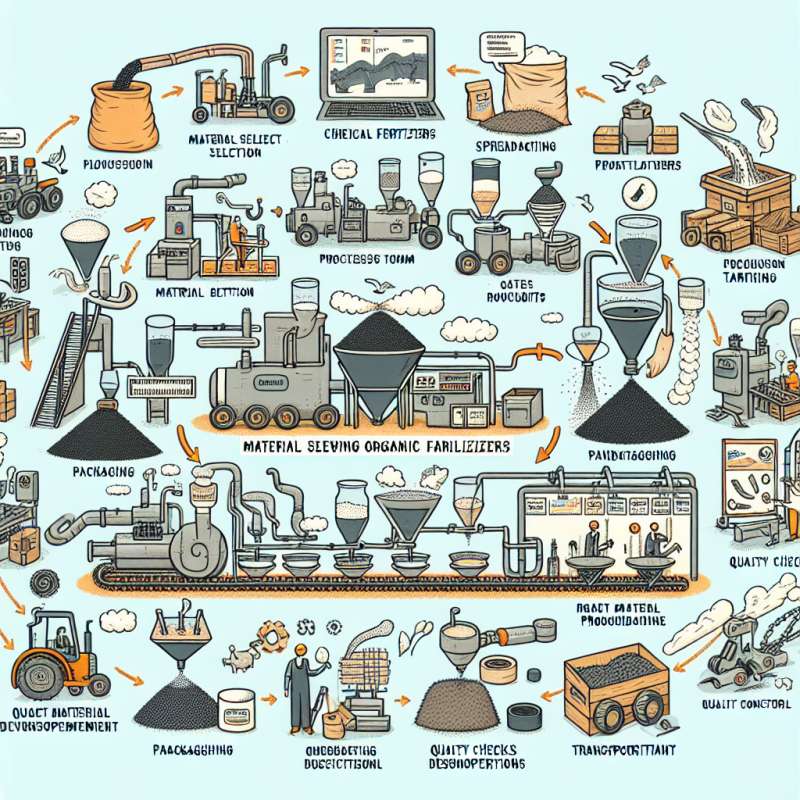

在農業生產中,複合肥料是一種非常重要的肥料形式。複合肥料可以滿足植物生長的多種營養需求,提高農產品的產量和質量。複合肥料的製造過程主要包括混合、配方、加工、撒布等多個步驟。

首先,選擇合適的有機肥料和化學肥料作為原料。然後利用混合機將這些原料混合均勻,形成混合肥料成分。接著根據要求,在混合肥料中添加適量的營養元素,製成具有特定配方的複合肥料。

在製造過程中,使用撒布機將複合肥料均勻地撒布在田地或農作物上。同時,在製造過程中需要對產品進行包裝、檢驗和質量控制,以確保生產的複合肥料質量符合標準。

為了提高生產效率,許多生產廠家都會引入输送线設備,將複合肥料在生產線上自動傳送,減少人力成本,提高生產效率。

通過以上的過程,最終生產出的複合肥料能夠有效地提高農業產品的產量和品質,為農業生產提供了有力的支持。

English:

Keywords: mixer, spreader, conveyor belt

Title: The production process of compound fertilizers

Article: In agricultural production, compound fertilizers are essential for providing a variety of nutrients to plants and improving crop yield and quality. The production process of compound fertilizers includes mixing, formulation, processing, spreading, and other steps.

Firstly, suitable organic and chemical fertilizers are selected as raw materials. These raw materials are then mixed evenly using a mixer to create the compound fertilizer components. Nutrient elements are added to the compound fertilizer to create a specific formulation as required.

During the manufacturing process, a spreader is used to evenly distribute the compound fertilizer in fields or on crops. Additionally, packaging, inspection, and quality control are necessary to ensure the produced compound fertilizers meet standards.

To enhance production efficiency, many manufacturers use conveyor belt equipment to automatically transport compound fertilizers on the production line, reducing labor costs and increasing efficiency.

Through these processes, the final compound fertilizers produced effectively improve agricultural product yield and quality, providing strong support for agricultural production.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)