近年來,隨著科技的迅速發展,工程領域和電腦科學的融合越來越緊密。特別是在專用機械設備製造和化工機械設備製造這兩個領域,工程和電腦的結合不僅提高了生產效率和精確度,還帶來了許多創新的可能性。本文將探討這一趨勢的未來發展以及與之相關的關鍵技術。

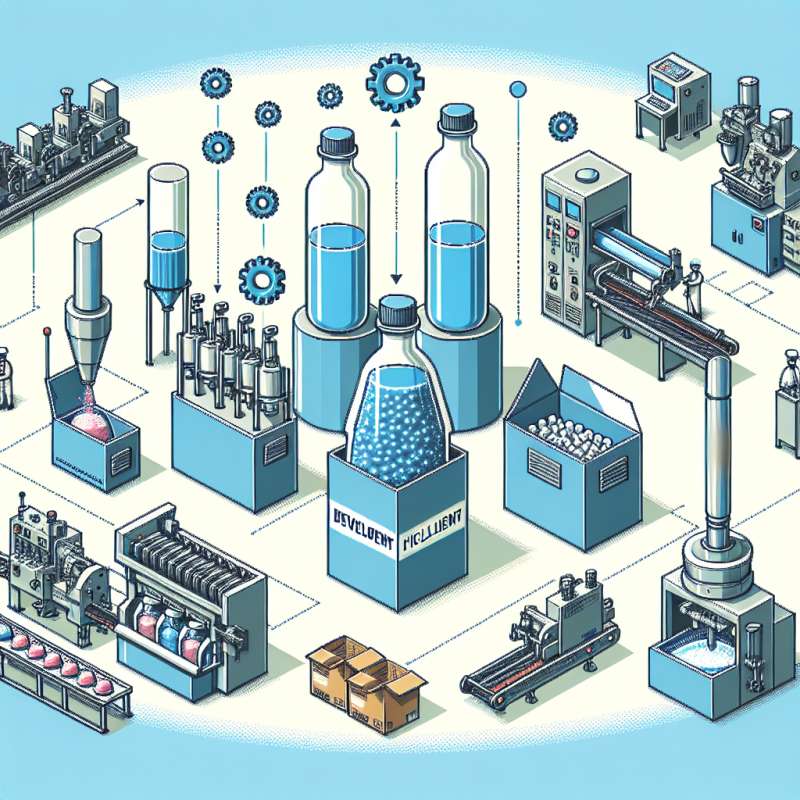

在未來的發展中,工程和電腦的融合將成為一個重要的趨勢。這種融合使得專用機械設備製造和化工機械設備製造更加智能化和自動化。例如,在工程領域中,智能機器人的應用已經大大提高了生產效率和產品品質。而在化工領域中,借助電腦的模擬和控制技術,可以實現更加準確和節能的生產過程。

除了智能化和自動化,未來還將出現更多創新的技術和機械設備。一個關鍵的趨勢是三維打印技術的應用。這種技術可以實現對機械零件的快速打印和定制化生產,大大縮短了生產週期和成本。同時,這種技術還可以實現一些傳統製造方法難以實現的複雜結構和設計。

此外,還有一些其他的關鍵技術值得關注。例如,物聯網技術的發展使得機械設備之間能夠實現實時監控和數據交換,從而達到更加高效的生產管理和維護。而人工智能的應用則可以實現機器自主學習和優化,從而進一步提高生產效率和品質。

總之,工程和電腦的融合將是專用機械設備製造和化工機械設備製造未來的發展趨勢。這種融合不僅提高了生產效率和品質,還帶來了許多創新的可能性。三維打印技術、物聯網和人工智能等關鍵技術的應用將使得工程和電腦的結合更加緊密,為未來的發展提供更多的機遇和挑戰。

Keyword: Engineering, Computer, Special Machinery Manufacturing, Chemical Machinery Manufacturing

Title: Future Development Trends in Special Machinery Manufacturing: Integration of Engineering and Computer

Article:

In recent years, with the rapid advancement of technology, the integration of engineering and computer science has become increasingly prominent. This is particularly evident in the fields of special machinery manufacturing and chemical machinery manufacturing, where the combination of engineering and computer technology has not only increased production efficiency and precision but also brought about numerous innovative possibilities. This article explores the future development trends in this area and the key technologies associated with it.

In the future, the integration of engineering and computer science will become a crucial trend in special machinery and chemical machinery manufacturing. This integration will make these fields more intelligent and automated. For instance, in the field of engineering, the application of intelligent robots has greatly enhanced production efficiency and product quality. In the chemical field, the use of computer simulation and control technology enables more accurate and energy-efficient production processes.

Alongside intelligence and automation, there will also be further innovative technologies and machinery equipment in the future. One key trend is the application of 3D printing technology. This technology enables the rapid printing and customized production of mechanical parts, significantly reducing production cycles and costs. Additionally, this technology allows for the realization of complex structures and designs that were difficult to achieve with traditional manufacturing methods.

Furthermore, several other key technologies are worth mentioning. For example, the development of the Internet of Things enables real-time monitoring and data exchange among machinery equipment, leading to more efficient production management and maintenance. The application of artificial intelligence enables machine autonomy, learning, and optimization, further enhancing production efficiency and quality.

In conclusion, the integration of engineering and computer science is a future development trend in special machinery manufacturing and chemical machinery manufacturing. This integration not only improves production efficiency and quality but also brings about various innovative possibilities. The application of 3D printing technology, the Internet of Things, and artificial intelligence further strengthens the bond between engineering and computer science, providing more opportunities and challenges for future development.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)