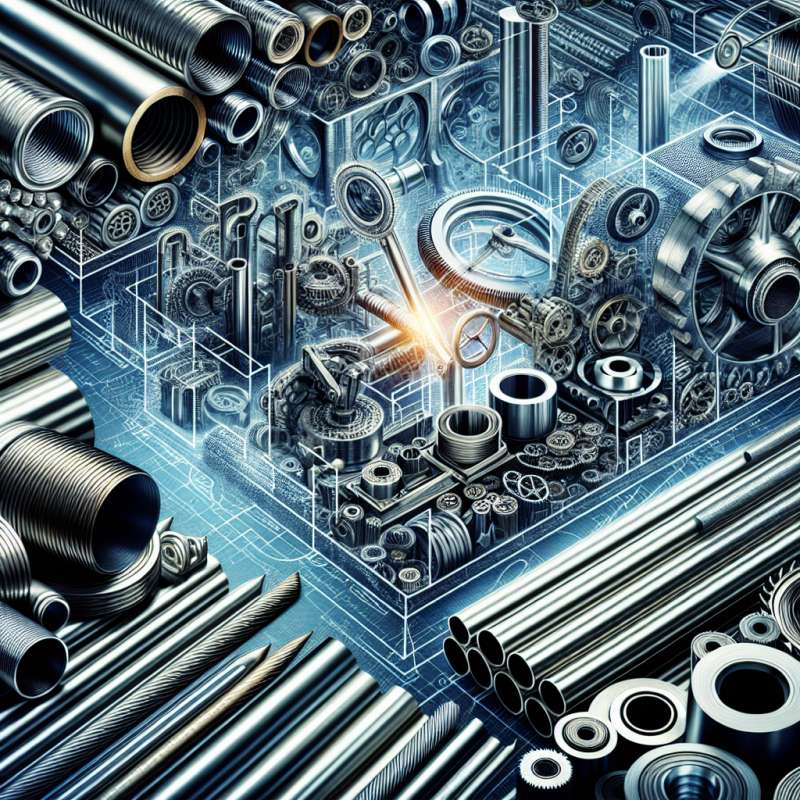

隨著科技的不斷進步和人們對醫療品質要求的提高,精密零件在醫療領域中的應用越來越廣泛。而不銹鋼作為一種耐腐蝕、耐高溫的材料,在製造精密零件方面具有獨特的優勢。本文將探討不銹鋼精密零件在醫療領域中的未來發展趨勢。

隨著科技的進步,醫療設備變得更加精密和高效。不銹鋼精密零件在這一趨勢下扮演著重要的角色。不銹鋼具有耐腐蝕、不易受汙染且易於清潔的特性,使其成為製造醫療設備的理想選擇。例如,不銹鋼的耐蝕性使其成為製造醫療器械和手術器械的理想材料。另外,不銹鋼能夠承受高溫,這使得它成為製造高溫消毒設備的首選材料。

不銹鋼精密零件在醫療領域中的應用不僅局限於設備和器械的製造,還延伸到人體內部。隨著微創手術和植入設備的發展,不銹鋼精密零件的需求將進一步增加。例如,在心臟導管手術中使用的支架和夾具通常由不銹鋼製成,以確保材料的耐壓性和耐磨性。此外,不銹鋼精密零件還廣泛應用於人工關節、植入式心臟起搏器和其他植入式醫療設備的製造中。

未來,不銹鋼精密零件在醫療領域中的應用將持續擴大。隨著醫療科技的不斷發展,對高精度和高可靠性的需求將逐漸增加。因此,不銹鋼精密零件的製造技術和工藝也將不斷進步。使用先進的製造技術,例如3D列印和精密加工,可以生產出更複雜和高品質的不銹鋼精密零件,以滿足不斷提高的醫療需求。

總結而言,不銹鋼精密零件在醫療領域中具有無限的潛力和發展空間。它們的耐腐蝕性和高耐磨性使其成為製造醫療設備和器械的理想材料。隨著醫療科技的不斷進步,不銹鋼精密零件的需求將不斷增加。未來的發展趨勢將集中在提高製造技術和工藝,以生產更高品質的不銹鋼精密零件來滿足日益增長的醫療需求。

關鍵字:stainless steel, precision, medical, parts, future development trends

Title: Future Development Trends of Stainless Steel Precision Parts in the Medical Field

Article:

With the continuous advancement of technology and the increasing demand for healthcare quality, the application of precision parts in the medical field is becoming more widespread. Stainless steel, as a corrosion-resistant and high-temperature resistant material, has unique advantages in manufacturing precision parts. This article explores the future development trends of stainless steel precision parts in the medical field.

With technological progress, medical equipment has become more precise and efficient. Stainless steel precision parts play an important role in this trend. Stainless steel's corrosion resistance, contamination resistance, and ease of cleaning make it an ideal choice for manufacturing medical equipment. For example, stainless steel's corrosion resistance makes it an ideal material for manufacturing medical instruments and surgical tools. Additionally, stainless steel's ability to withstand high temperatures makes it the preferred material for manufacturing high-temperature sterilization equipment.

The application of stainless steel precision parts in the medical field is not limited to the manufacturing of equipment and instruments but also extends to the human body. With the development of minimally invasive surgery and implantable devices, the demand for stainless steel precision parts will further increase. For example, stents and fixtures used in cardiac catheterization procedures are often made of stainless steel to ensure the material's pressure resistance and wear resistance. Furthermore, stainless steel precision parts are widely used in the manufacturing of artificial joints, implantable pacemakers, and other implantable medical devices.

In the future, the application of stainless steel precision parts in the medical field will continue to expand. As medical technology continues to advance, the demand for high precision and reliability will gradually increase. Therefore, the manufacturing techniques and processes for stainless steel precision parts will continue to improve. Advanced manufacturing technologies such as 3D printing and precision machining can produce more complex and high-quality stainless steel precision parts to meet the increasing healthcare demands.

In conclusion, stainless steel precision parts have unlimited potential and development space in the medical field. Their corrosion resistance and high wear resistance make them an ideal material for manufacturing medical equipment and instruments. With the continuous advancement of medical technology, the demand for stainless steel precision parts will continue to grow. Future development trends will focus on improving manufacturing techniques and processes to produce higher-quality stainless steel precision parts to meet the ever-increasing healthcare demands.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)