鋼筋和棒鋼是建築業中常見的建材,它們在建築結構的加固和支撐中起著重要作用。這些材料主要是由專業的生產廠家進行製造,通過一系列的工藝過程製成。

首先,鋼筋和棒鋼的製造過程都需要用到高品質的鋼材作為原料。這些鋼材經過特殊的處理和加工,使其具有強度和彈性,以滿足建築物的需求。

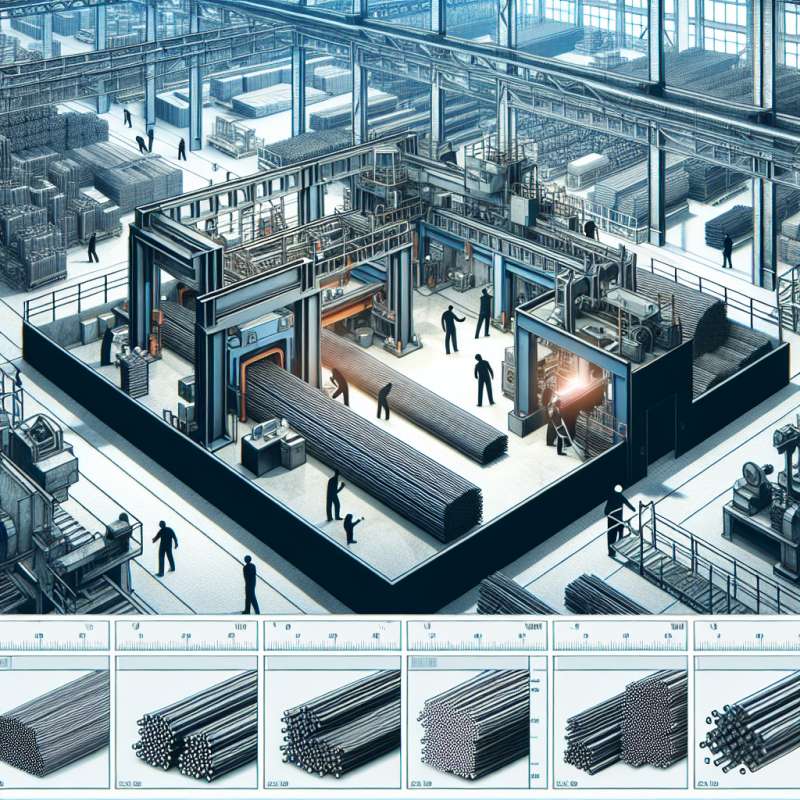

生產廠家會將原料鋼材進行加熱處理,然後通過機器將其拉拔成不同直徑和長度的鋼筋或棒鋼。這些產品在製造過程中需要具備一定的精度和強度,以確保其在建築中的使用效果。

製成的鋼筋和棒鋼會根據客戶的要求進行包裝和運輸,最終送達施工現場。這些材料被廣泛應用於樓宇、橋樑和其他建築工程中,為建築物的穩固提供了有力支持。

總的來說,鋼筋和棒鋼的製造過程需要嚴格的控制和專業技術,生產廠家扮演著重要的角色。只有通過不斷優化和提升製造工藝,才能生產出高質量的建築材料,為建築業貢獻力量。

Keywords: rebar, steel bar, manufacturing, production manufacturer

Title: Manufacturing and production of rebar and steel bar

Article: Rebar and steel bars are common construction materials that play important roles in reinforcing and supporting building structures. These materials are primarily manufactured by professional production manufacturers through a series of processes.

Firstly, the manufacturing process of rebar and steel bars requires high-quality steel as raw material. These steels are treated and processed to give them strength and elasticity to meet the needs of the buildings.

Production manufacturers heat the raw steel materials and then draw them into different diameters and lengths of rebar or steel bars using machines. These products require a certain level of precision and strength during manufacturing to ensure their effectiveness in construction.

The produced rebar and steel bars are packaged and transported according to customers' requirements and finally delivered to construction sites. These materials are widely used in buildings, bridges, and other construction projects to provide strong support for the structures.

In conclusion, the manufacturing process of rebar and steel bars requires strict control and professional techniques, with production manufacturers playing a crucial role. Only through continuous optimization and improvement of manufacturing processes can high-quality construction materials be produced to contribute to the construction industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)