近年來,隨著科技的進步和產業的發展,電子設備的需求不斷增長。在製造電子設備的過程中,點焊點銲、SCR控制板設計、氬焊機控制板設計和龍門點焊控制器等技術成為至關重要的一環。

點焊點銲是電子設備製造中常用的焊接方式,其穩定性和可靠性影響著產品的品質。SCR控制板設計則是用於控制電子設備中的功率轉換,保證設備的高效運行。而氬焊機控制板設計則是用於控制氬焊機的焊接過程,確保焊接的精準度和效率。龍門點焊控制器則是用於大型電子設備的焊接,提高了生產效率和品質穩定性。

隨著市場對電子設備的需求持續增長,這些控制技術的需求也在逐漸擴大。製造廠商需不斷提升技術水平,開發符合市場需求的產品,以滿足客戶對品質和效率的要求。機電、電信及電路設備安裝市場也將因此獲得更大的發展空間。

Key words: Spot welding, SCR control board design, Argon welding machine control board design, Gantry spot welding controller

Title: Market Demand Analysis for Electronic Equipment Control Technology

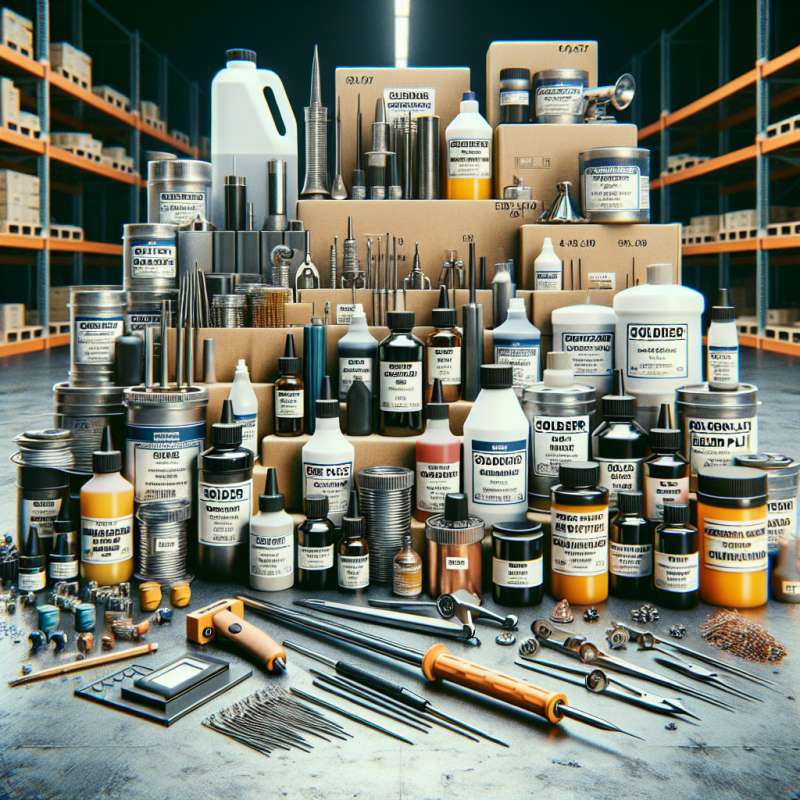

Article: In recent years, with the advancement of technology and the development of industries, the demand for electronic equipment has been continuously growing. In the process of manufacturing electronic equipment, technologies such as spot welding, SCR control board design, argon welding machine control board design, and gantry spot welding controller have become crucial components.

Spot welding is a commonly used welding method in the manufacturing of electronic equipment, and its stability and reliability directly impact the quality of the products. SCR control board design is used to control the power conversion in electronic equipment, ensuring its efficient operation. Meanwhile, argon welding machine control board design is crucial for controlling the welding process of argon welding machines to ensure precision and efficiency in the welding process. Gantry spot welding controller is used for large electronic equipment welding, improving production efficiency and quality stability.

With the continuous growth in market demand for electronic equipment, the demand for these control technologies is gradually expanding. Manufacturers need to constantly improve their technical capabilities and develop products that meet market demands to satisfy customers' requirements for quality and efficiency. The market for the installation of electromechanical, telecommunications, and circuit equipment will also have a greater room for development as a result.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)