近年來,隨著科技的發展和市場需求的增長,金屬製品製造行業的機械加工成為了一個熱門話題。CNC加工、多軸鑽床加工、CNC銑床、以及CNC車床等先進的加工技術正逐漸取代傳統的手工加工,使製造流程更高效、精確。

其中,CNC加工技術不僅可以提高生產效率,還可以提高產品的精度和質量。這種技術可以應用於建材五金(螺絲、螺帽、鉚釘等金屬製品)的批發和生產,也可以應用於機械器具的批發業務中。因此,許多公司紛紛投資於引進這些先進的機械設備。

而隨著中壢、平鎮、桃園等地的金屬製品製造業愈發蓬勃,對機械加工技術的需求也愈發增長。儘管市場競爭激烈,但只有掌握了先進的技術和加工設備,企業才能在這個市場中脫穎而出。

因此,金屬製品製造行業逐漸走向全面智能化和自動化,機械加工技術的應用範圍正在不斷擴大。隨著市場需求的增長,這個行業有望迎來更大的發展空間。

Keywords: CNC machining, metal product manufacturing, wholesale of machinery and equipment

Title: Trends in Mechanical Processing in the Metal Product Manufacturing Industry

Article:

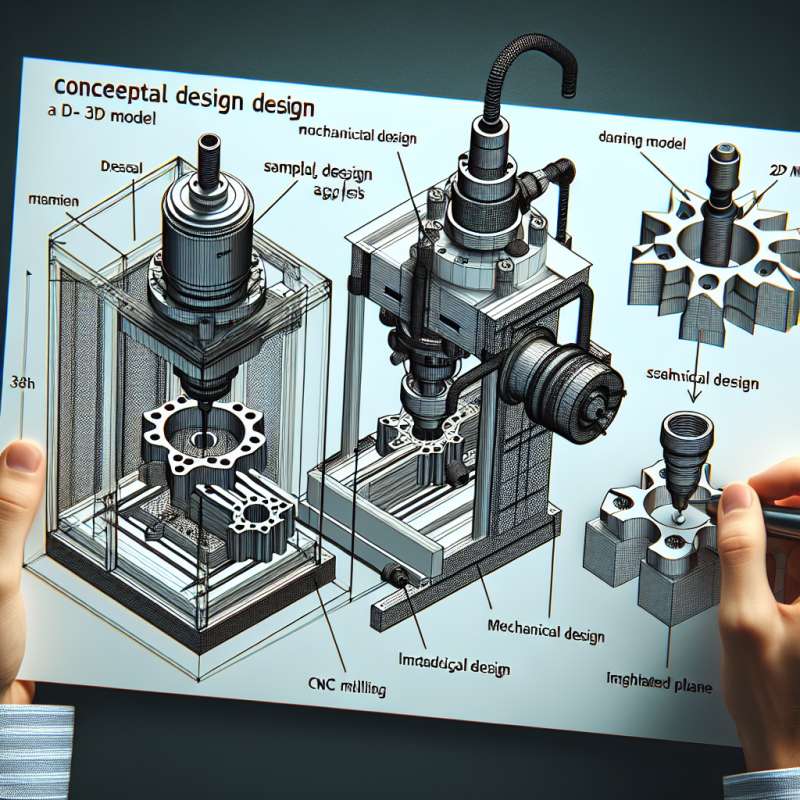

In recent years, with the development of technology and the growth of market demand, mechanical processing in the metal product manufacturing industry has become a hot topic. Advanced processing techniques such as CNC machining, multi-axis drilling, CNC milling, and CNC turning are gradually replacing traditional manual processing methods, making the manufacturing process more efficient and precise.

Among these techniques, CNC machining not only improves production efficiency but also enhances the precision and quality of products. This technology can be applied to the wholesale and production of building materials and hardware (such as screws, nuts, rivets, and other metal products), as well as in the wholesale business of machinery and equipment. Therefore, many companies are investing in the introduction of these advanced machinery.

As the metal product manufacturing industry in cities like Zhongli, Pingzhen, and Taoyuan continues to thrive, the demand for mechanical processing technology is also increasing. Despite fierce market competition, only by mastering advanced technology and processing equipment can companies stand out in this market.

Thus, the metal product manufacturing industry is moving towards comprehensive intelligence and automation, and the application range of mechanical processing technology is expanding. With the growth of market demand, this industry is expected to see greater development opportunities.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)