近年來,隨著科技的進步和製造業的發展,CNC銑床加工和CNC車床加工成為了機械製造業中不可或缺的一部分。這些先進的加工技術不僅提高了生產效率,還改善了產品的質量和精度。此外,OEM製造也在不斷發展壯大,成為了許多企業的重要業務之一。

CNC銑床加工和CNC車床加工使用電腦數控技術,能夠快速、精準地處理各種材料,包括金屬、塑料和木材。這些加工技術具有自動化、高效率和高精度的特點,可應用於各種行業,如汽車、航空航天、電子和能源等。隨著新材料和新技術的不斷推出,CNC加工技術也在不斷演進和創新。

OEM(原始設備製造)製造是一種專門為其他公司生產產品的製造業務模式。這種模式可以有效地提高生產效率和降低成本,同時讓企業專注於自己的核心業務。在機械製造領域,許多企業將OEM製造作為其主要業務之一,為客戶提供各種定制化的產品和解決方案。

零件加工中心是一種專門從事零件加工的機械廠。這些廠家擁有先進的加工設備和技術,能夠根據客戶的需求生產各種零件和零組件。隨著制造技術的不斷進步和客戶對產品質量和交貨時間的要求越來越高,零件加工中心的需求也越來越大。

除了上述關鍵字所涵蓋的機械製造業,還有一些未分類其他機械器具批發的企業也在不斷發展壯大。這些企業通常專門從事機械器具的批發和銷售,以滿足不同行業的需求。隨著經濟的發展和產業的多元化,這些企業的市場前景也非常廣闊。

總的來說,CNC加工和OEM製造是未來機械製造業的重要發展趨勢。隨著科技的不斷進步和製造技術的不斷創新,這些加工技術將繼續發揮重要作用,推動產業的發展和進步。同時,零件加工中心和未分類其他機械器具批發企業也將隨著市場需求的增加而迎來更好的發展機會。

Keyword: CNC milling machine, CNC lathe machine, OEM, parts processing center, wholesale of miscellaneous machinery and equipment

Title: CNC Machining and OEM Manufacturing: Future Trends in the Mechanical Industry

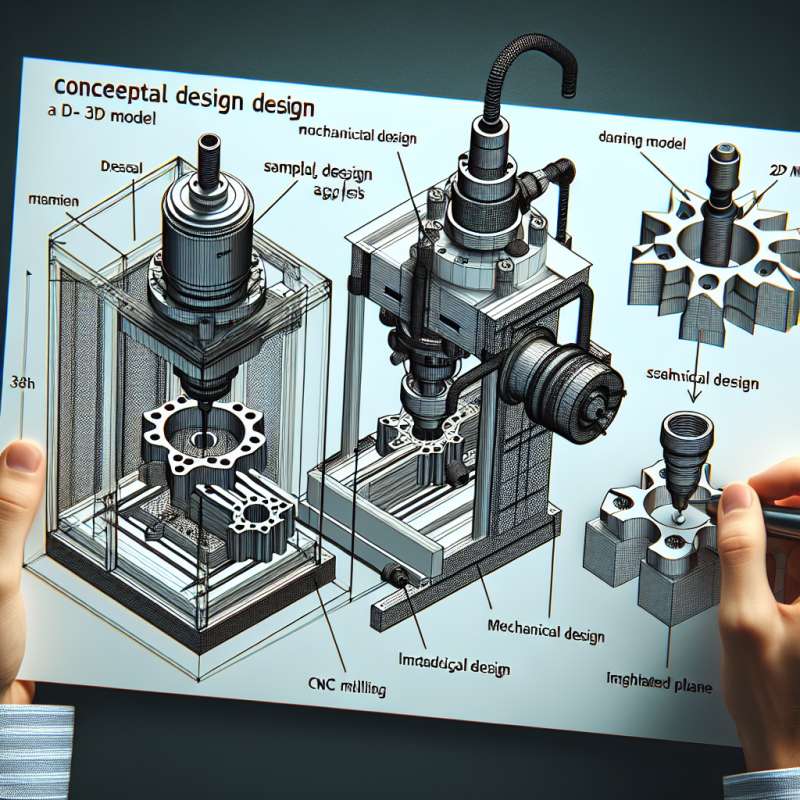

Article: In recent years, with the advancement of technology and the development of the manufacturing industry, CNC milling machine and CNC lathe machine have become essential parts of the mechanical manufacturing industry. These advanced machining technologies not only improve production efficiency but also enhance product quality and precision. In addition, OEM manufacturing is also growing and becoming an important business for many companies.

CNC milling machine and CNC lathe machine utilize computer numerical control technology to process various materials, including metals, plastics, and wood, quickly and accurately. These machining technologies are characterized by automation, high efficiency, and high precision, and they can be applied in various industries such as automotive, aerospace, electronics, and energy. As new materials and technologies are constantly introduced, CNC machining technology is also evolving and innovating.

OEM (Original Equipment Manufacturing) manufacturing is a business model specialized in producing products for other companies. This model can effectively improve production efficiency and reduce costs while enabling companies to focus on their core businesses. In the field of mechanical manufacturing, many companies consider OEM manufacturing as one of their main businesses, providing customers with various customized products and solutions.

A parts processing center is a mechanical factory specialized in parts processing. These factories have advanced processing equipment and technologies to produce various parts and components according to customer needs. With the continuous advancement of manufacturing technology and the increasing customer demands for product quality and delivery time, the demand for parts processing centers is also growing.

In addition to the mechanical manufacturing covered by the above keywords, there are also enterprises engaged in the wholesale of miscellaneous machinery and equipment that are constantly growing. These enterprises generally specialize in the wholesale and sales of machinery and equipment to meet the needs of different industries. With economic development and industrial diversification, these enterprises have broad market prospects.

In conclusion, CNC machining and OEM manufacturing are important trends in the future of the mechanical manufacturing industry. With the continuous advancement of technology and innovation in manufacturing technology, these machining technologies will continue to play a crucial role in driving the development and progress of the industry. Meanwhile, parts processing centers and enterprises engaged in the wholesale of miscellaneous machinery and equipment will also have better development opportunities with the increasing market demand.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)