近年來,LED產業蓬勃發展,對環保和節能的需求讓LED照明產品越來越受到廣泛關注。LED燈具的核心組件之一就是LED晶圓,而晶圓的製造過程中繞線技術起著至關重要的作用。

晶圓是LED製造的起點,而其製造過程中需要將線圈嵌入其中,以完成LED元件的構造。為了提高製造效率和增強產品質量,金屬製品製造廠商通常會投資購買先進的繞線機。這些繞線機具有高速度和高精度的特點,能夠快速且精準地完成線圈的繞製工作。

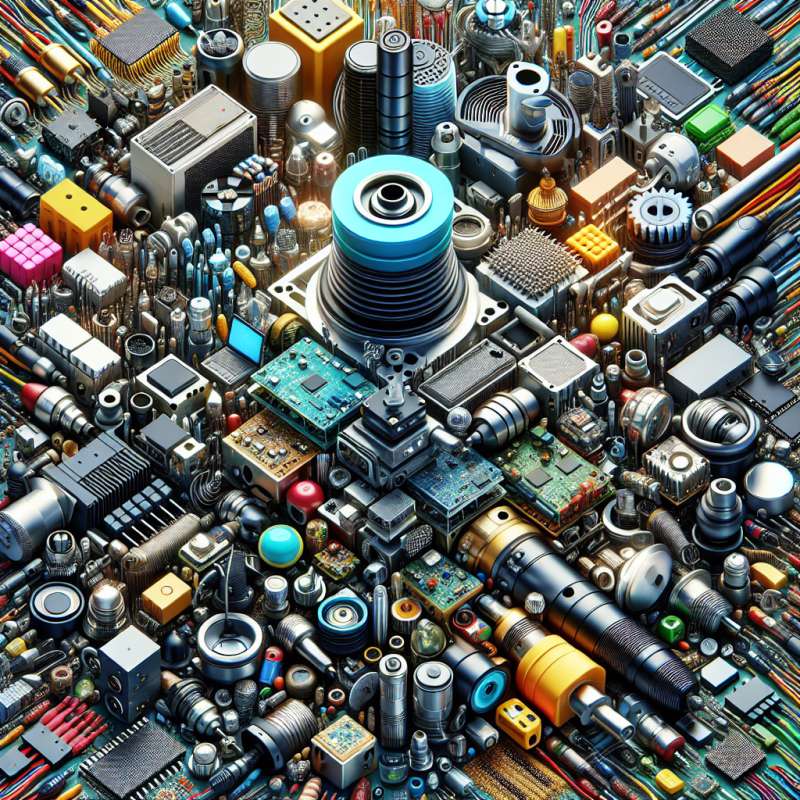

透過繞線機,LED製造廠商可以有效控制線圈的形狀和大小,確保LED元件的性能和品質。同時,繞線機也可以應用於其他產品的製造過程中,如繼電器、變壓器等電子元件的生產。

隨著LED產業的持續發展,繞線機在LED晶圓製造中的應用也將更加廣泛。金屬製品製造廠商可以通過提供先進的繞線機和相關技術服務,為LED製造廠商提供更多生產解決方案,進一步促進LED產業的發展。

Keywords: Wafer, LED, Winding Machine, Metal Product Manufacturing

Title: Application of Winding Machine in LED Wafer Manufacturing

Article: In recent years, the LED industry has been thriving, with increasing attention to environmental protection and energy efficiency driving the popularity of LED lighting products. One of the core components of LED fixtures is the LED wafer, and the winding technology plays a crucial role in the manufacturing process of wafers.

The wafer is the starting point of LED manufacturing, and during its production process, coils need to be embedded in it to complete the construction of LED components. In order to improve manufacturing efficiency and enhance product quality, metal product manufacturers often invest in advanced winding machines. These winding machines are characterized by high speed and high precision, allowing for rapid and precise winding of coils.

Through the use of winding machines, LED manufacturers can effectively control the shape and size of coils to ensure the performance and quality of LED components. Additionally, winding machines can be applied in the manufacturing processes of other products, such as relays, transformers, and other electronic components.

With the continuous development of the LED industry, the application of winding machines in LED wafer manufacturing will become more widespread. Metal product manufacturers can provide advanced winding machines and related technical services to offer LED manufacturers more production solutions, further promoting the development of the LED industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)