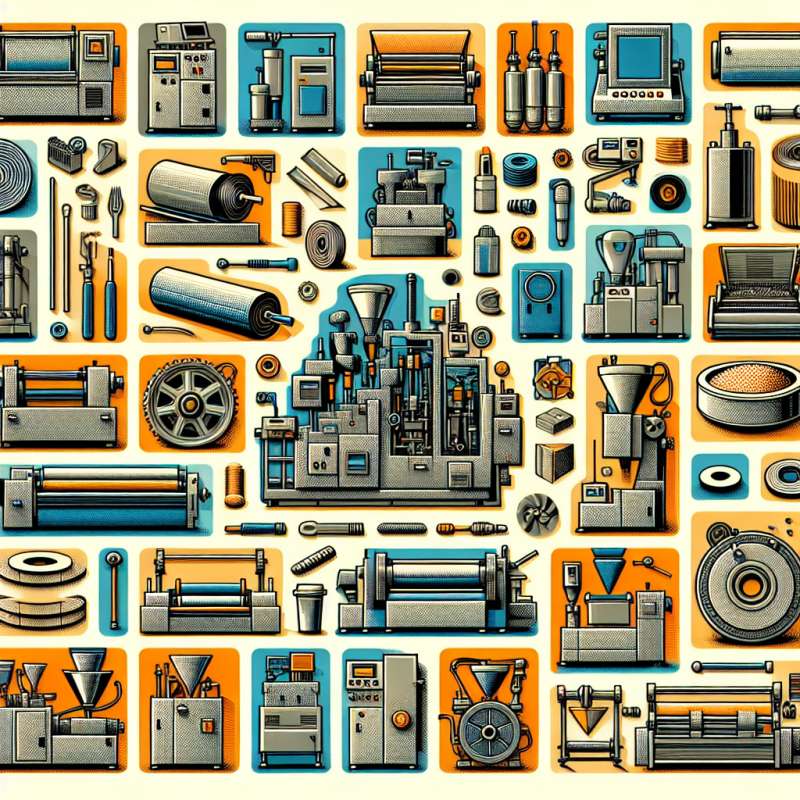

近年來,工業設備製造業在橡膠加工機械和塑膠注塑機領域展開了一系列的技術創新。通過提升自主研發能力和生產技術水平,機械設備製造商致力於提高產品品質和生產效率。

橡膠加工機械是農用機械和林用機械中不可或缺的一環,其主要作用是將原材料加工成各種橡膠製品。隨著科技的發展,橡膠加工機械產品在性能和精度上都有了顯著的提升,同時也更加節能環保。

而塑膠注塑機則是製造塑膠製品的關鍵設備之一。隨著人們對塑膠製品需求的不斷增加,塑膠注塑機行業也隨之發展。現代塑膠注塑機已經實現了數控化、自動化,大大提高了生產效率和製品質量。

機械設備製造業的技術創新不僅促進了製造業的轉型升級,也推動了整個產業的發展。未來,隨著科技的不斷進步,橡膠加工機械和塑膠注塑機將會迎來更多的創新和突破。

Keyword: Machinery Equipment Manufacturing, Rubber Processing Machinery, Plastic Injection Molding Machine

Title: Technological Innovation in Industrial Equipment Manufacturing Industry

Article: In recent years, the industrial equipment manufacturing industry has launched a series of technological innovations in the fields of rubber processing machinery and plastic injection molding machines. By enhancing independent research and development capabilities and production technology levels, machinery equipment manufacturers are committed to improving product quality and production efficiency.

Rubber processing machinery is an indispensable part of agricultural and forestry machinery, whose main function is to process raw materials into various rubber products. With the development of technology, rubber processing machinery products have significantly improved in performance and accuracy, while also being more energy-efficient and environmentally friendly.

Plastic injection molding machines are one of the key equipment for manufacturing plastic products. With the increasing demand for plastic products, the plastic injection molding machine industry has also developed. Modern plastic injection molding machines have achieved numerical control and automation, greatly improving production efficiency and product quality.

Technological innovation in the machinery equipment manufacturing industry not only promotes the transformation and upgrading of the manufacturing industry but also drives the development of the entire industry. In the future, with the continuous advancement of technology, rubber processing machinery and plastic injection molding machines will experience more innovation and breakthroughs.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)